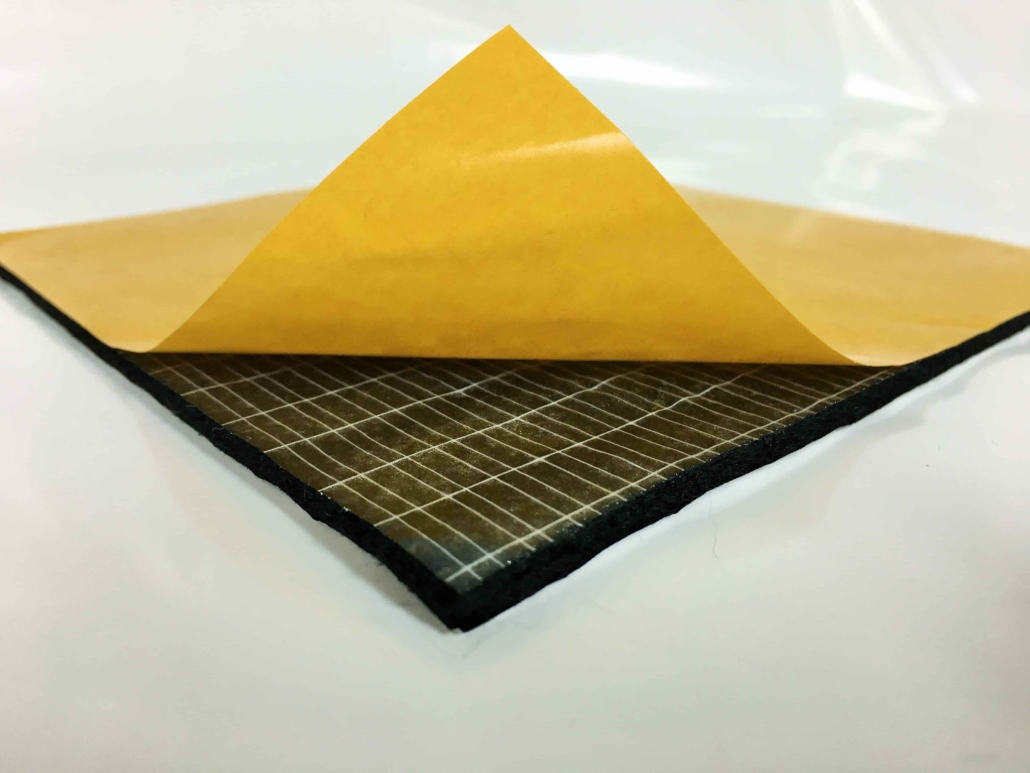

Under what circumstances will the protective film be easily torn

There are several situations where a protective film is prone to tearing when being peeled off:

1. Fragile material: Some protective films may be made from fragile materials that are prone to breakage or tearing when peeled off. This could be due to the inherent characteristics of the material, such as polyethylene film, polyvinyl chloride film, etc.

2. Strong adhesion of the protective film: If the protective film has excessive adhesion during use or if the adhesion increases over time, it can result in tearing or fragmentation when peeled off.

3. Environmental factors: Special environmental conditions such as high temperatures, low temperatures, or humidity can affect the performance of the protective film, making it more fragile and susceptible to tearing.

4. Aging of the protective film: When a protective film is exposed to sunlight or UV radiation, or undergoes repeated use over a long period, it may experience aging and degradation, making the film more brittle and easier to tear.

5. Improper peeling method: Using inappropriate force or methods, such as peeling too forcefully or hastily, can cause the film to tear or fragment.

To avoid issues with protective film tearing, consider the following:

1. Use high-quality protective films and select materials and specifications suitable for the application.

2. Peel off the protective film within a suitable timeframe to avoid prolonged exposure and aging.

3. Set and control the usage environment based on environmental conditions and the characteristics of the protective film.

4. Use appropriate peeling methods to avoid excessive force or rapid.

If you are interested in our products, please feel free to contact us!

Leave a Reply

Want to join the discussion?Feel free to contribute!