UV degumming pressure sensitive adhesive for porous substrates

UV degumming pressure sensitive adhesive for porous substrates

Porous ceramic materials including anodized alumina are increasingly used in appearance parts in the consumer electronics industry. In the process of processing porous materials, it is necessary to use protective film such as tape for temporary protection. The surface of anodized alumina used in the back shell of mobile phones has a large number of nanoscale pores. The adhesive force of the typical protective film tape on the porous surface is very poor, and it is easy to fall off when the back cover is processed by computer numerical control (CNC), which does not provide adequate protection.

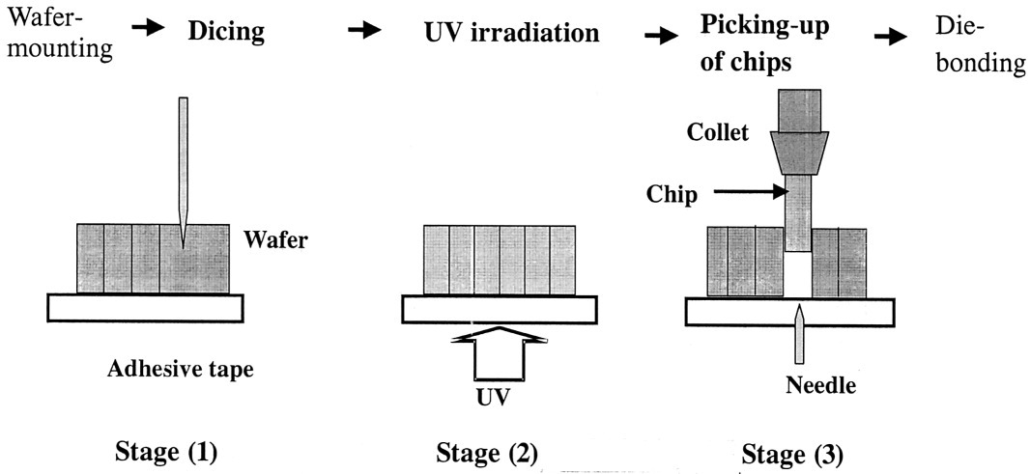

And the high viscosity of the protective film, the adhesive layer is easy to penetrate the microhole, when the removal of the protective film will form residual glue, and the removal force is large, the need for an additional cleaning process. Pressure sensitive adhesives that can be UV – bonded have been used for protective film tape. UV photodesinking pressure sensitive adhesive is also known as UV drinking adhesive, which refers to a class of pressure sensitive adhesives that can reduce the adhesion through UV photoexcitation. UV viscose has the characteristics of easy construction, high initial adhesion, and easy removal after UV viscose.

Existing UV adhesives typically consist of pressure sensitive adhesives, UV-polymerizable oligomers (also known as UV oligomers, or adhesives), and free radical-type photoinitiators. Pressure sensitive adhesive provides initial bonding. When UV light is irradiated, UV oligomers crosslinking under the action of free radical photoinitiator makes the overall modulus of the de viscose adhesive improve. In this way, the adhesive layer hardens and loses its adhesion. UV adhesive as a protective film tape has a good initial adhesive relay, and in CNC processing will not fall off.

After processing, the adhesive tape is reduced by UV light, which can be easily removed. However, due to the limitation of their adhesive formulation, the unglued UV oligomers migrate into micropores when applied to porous surfaces. UV unglued, glue will further remain on the surface, difficult to remove clean. When color particles are added to the pores by subsequent nano-injection molding techniques to improve the appearance of anodic alumina, the appearance of anodic alumina will be seriously affected by residual de viscose adhesives, especially those migrating into micropores.

Leave a Reply

Want to join the discussion?Feel free to contribute!