Classification and research progress of traditional acrylic pressure sensitive adhesive

Traditional acrylate pressure-sensitive adhesives can be divided into three categories according to the curing method: non-crosslinked type, additional crosslinked dosage type, and self-crosslinked type. Non-crosslinked pressure sensitive adhesive coating has thermoplasticity after drying, so the cohesion is generally poor, and the adjustment of bonding property is difficult, in industrial production is not much application; Additional cross-linked acrylate pressure sensitive adhesive can be divided into peroxide cross-linked curing, isocyanate cross-linked curing, epoxy resin cross-linked curing, aziridine cross-linked curing, metal salt cross-linked curing, amine resin cross-linked curing pressure sensitive adhesive, etc., the use of external curing agent cross-linked acrylate pressure sensitive adhesive products more; Self-crosslinking acrylic pressure sensitive adhesive is prepared by introducing self-crosslinking monomers such as N-hydroxymethyl acrylamide and acrylic glycidyl ether copolymerization in the formula. Acrylate pressure-sensitive adhesive can be divided into solvent type, emulsion type, hot melt type, and radiation curing type.

Solvent-based acrylic pressure-sensitive adhesive

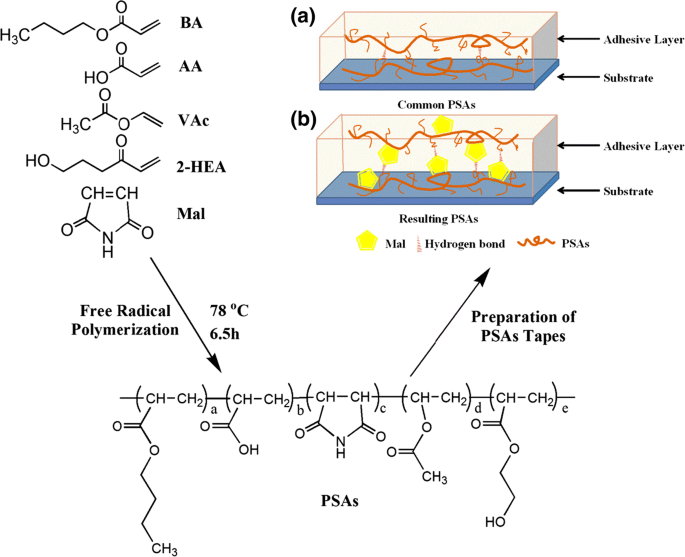

The solvent-based acrylic pressure-sensitive adhesive has the advantages of low molecular weight, good wettability, high initial viscosity, fast drying, and good water resistance, etc., it is widely used in the fields of pressure-sensitive label, packaging tape, stationery tape, and double-sided tape. Solv-based acrylate pressure-sensitive adhesive is mainly prepared by polymerization of the soft monomer, hard monomer, functional monomer, and solvent. The solvents used are mainly ethyl acetate and toluene. The chain transfer constants of acrylate monomers in different solvents are different, and the solvent has significant effects on molecular weight and distribution, viscosity, reaction rate, chain termination rate, etc. The properties of pressure-sensitive adhesives can be adjusted by changing the ratio of monomer and solvent, the type of initiator, reaction temperature, and polymerization process.

Emulsion acrylate pressure-sensitive adhesive

Emulsion acrylate pressure sensitive adhesive has the advantages of a simple production process, safe and convenient use, friendly to the environment, low cost, no pollution, short production cycle, good adhesion to all kinds of materials, colorless and transparent coating, but also has the disadvantages of poor high temperature and humidity resistance, poor water resistance, slow drying after coating, so it needs to be modified to improve its related performance.

At present, emulsion acrylate pressure-sensitive adhesive is developing in the direction of functionalization and diversification. The research direction is mainly modified by adding viscosifying emulsion, applying various new emulsifiers, adding organosilicon modification, and using the “core-shell emulsion polymerization” which can design and control the particle size of emulsion pressure-sensitive adhesive. Through the application of various modification methods, At the same time, the emulsion acrylate pressure-sensitive adhesive system with special functions is introduced to obtain emulsion pressure-sensitive adhesive with different functions, so as to meet the requirements of different fields.

Leave a Reply

Want to join the discussion?Feel free to contribute!