Solvent-free silicone pressure sensitive adhesive can be cured by silane addition reaction

Solvent-free organosilicon pressure-sensitive adhesive compositions can be cured by silane addition reaction. A pressure-sensitive adhesive laminate product prepared by curing the composition on a substrate can be used in electronic device applications for protection and/or masking during processing.

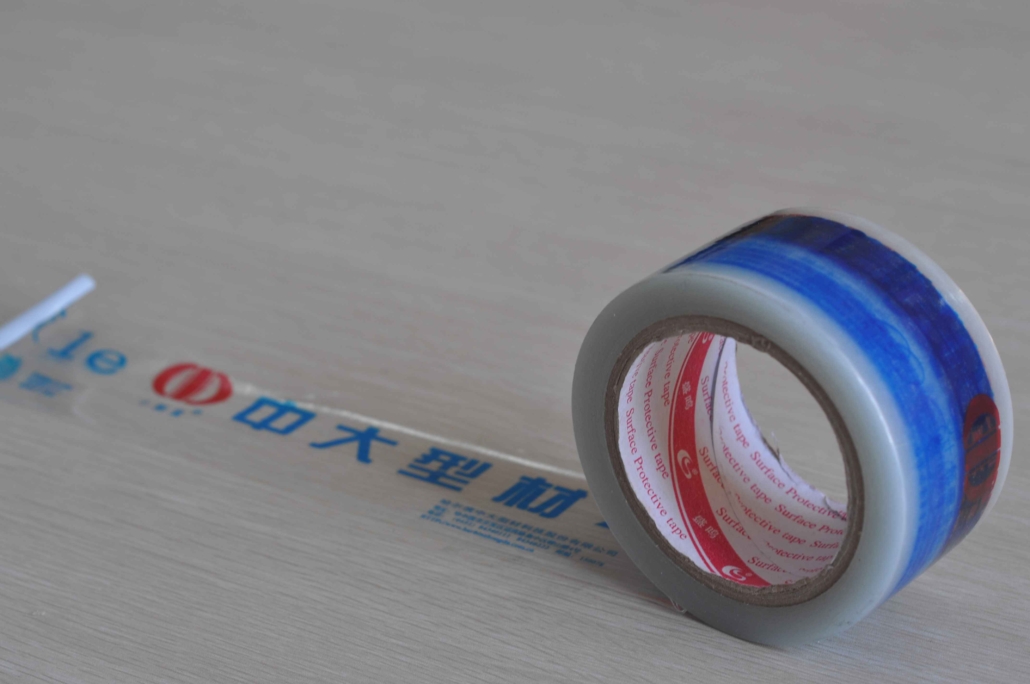

Protective film and carrier tape are the two main applications of organosilicon pressure-sensitive adhesives in the electronic device manufacturing industry. Generally, the thickness of the protective film and bearer tape medium pressure sensitive adhesive (PSA) is relatively thinner than that of traditional tape applications. Commercially available Psas for these applications are primarily solvent-based.

Consumers want solvent-free PSA because of environmental concerns and restrictions on volatile organic compounds. Relatively low viscosity is desirable for certain coating methods, such as those used to coat a relatively thin PSA layer to the substrate. For low viscosity, organosilicon polymers with short chains can be used in solvent-free PSA. However, solvent-free Psas with low viscosity can introduce a variety of problems, including electrostatic-induced or surface tension-induced flow of PSA compositions on the substrate surface, resulting in uneven adhesive coverage on the substrate and therefore uneven adhesive-coated surfaces.

The uneven adhesive covering on the substrate can suffer from the disadvantage of having too high adhesion for the protective film, in which case solvent-free PSA can cause damage to the protected substrate when the protective film is removed. In addition, uneven adhesive surfaces can suffer from the disadvantage of having unstable adhesion to the bearer band during machining protection, in which case surface damage or quality problems can result in surface protection and/or process masking when the bearer band is removed. Solvent-free pressure-sensitive adhesives with one or more of the following characteristics are required in the electronic device manufacturing industry: good machinability, suitable peeling strength, and a flat surface for the pressure-sensitive adhesive coating.

Leave a Reply

Want to join the discussion?Feel free to contribute!