Single layer PET protective film and double layer PET protective film feature introduction

PET properties: PET protective film material is transparent and colorless, the surface has been hardened; Data show that the general PET protective film material according to the different factory, the surface hardening value is between 3H~4H, which means that the better the surface hardening, the stronger its wear resistance. Another is the transmittance, which is also the main property of PET protective film material. The general transmittance is more than 90%. The transmittance determines the quality of a visual effect in the use of related instruments, and it has a good protective effect on the eyes.

PET protective film features:

- Surface resistance 107-109Ωcm, environmental protection, non-toxic and tasteless;

- No electrostatic material migration phenomenon on the surface of the product;

- 1000 level clean environment processing, excellent cleanliness;

- Excellent transparency, can be in the state of fitting protective material for optical film appearance inspection;

- Low viscosity, adhesive force changes little after attaching;

- Excellent anti-static effect, durable and stable performance;

- The product has single-side anti-static and double-side anti-static stripping voltage.

PET protective film can be divided into: single layer PET protective film, double layer PET protective film and three layers of PET protective film.

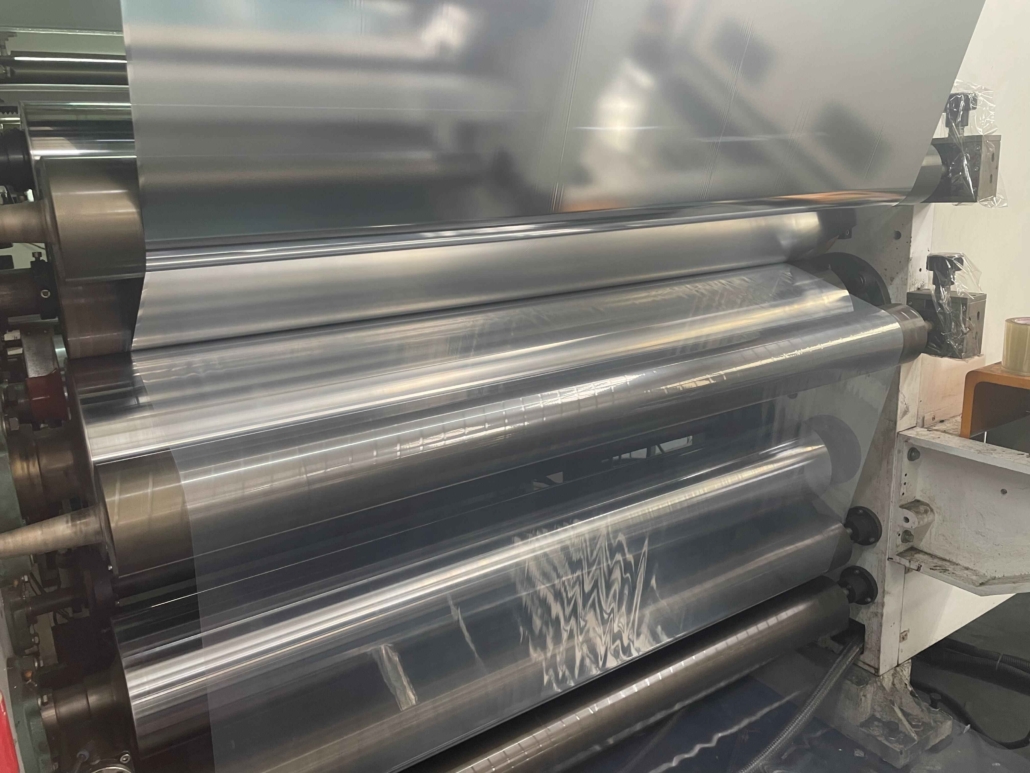

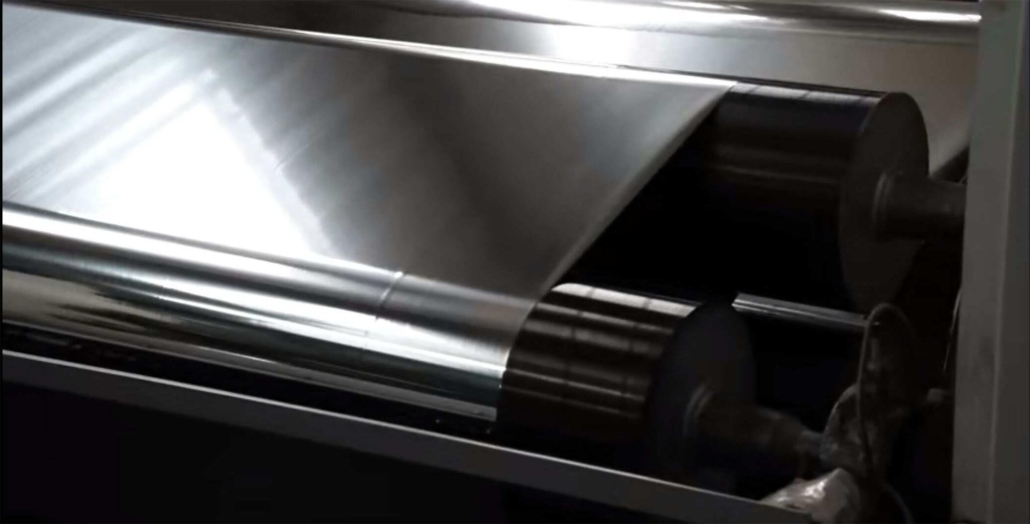

A, the structure of single layer PET: polyester film (PET) as a material, is based on polyethylene terephthalate ethanol fat as raw material, is made of extrusion thick sheet, and then made of bidirectional stretching film material, single coated silicone who made of single layer PET silicone protective film.

Thickness and viscosity of single layer PET protective film: thickness is 6C, viscosity is low viscosity, gram number is 1~2 grams.

Single layer PET use: mobile phone screen protection film, optical acrylic plate diffusion film, brightening film surface protection, liquid crystal panel, other smooth flat materials or workpiece processing protection.

Two, the structure of the double layer PET protective film: polyester film (PET) as the base material, polyethylene terephthalate as the raw material, the film material made by extrusion method; Single side coated silica gel, and release paper or release film and other release materials composite.

Characteristics of double layer PET protective film:

- Easy to peel, no residual glue, stable viscosity

- The protective film of the release material is dust-free coating, with high cleanliness

- Suitable for use in PC, PMMA, ABS, metal and glass material related products surface protection

Thickness and viscosity of double layer PET: the thickness is 6C, and the viscosity is divided into low viscosity and medium viscosity (the gram number of low viscosity is 1~2 grams).

The use of double layer PET: mobile phone lens, polarizer, LCD optical film during the process of surface protection film liquid crystal display panel, touch screen process protection, photoelectric material molding after the temporary carrier. The characteristics of double layer pet protective film are widely used, and as consumables in industrial production and life has been widely used.

Leave a Reply

Want to join the discussion?Feel free to contribute!