The Difference Between Regular Edge Film and Aluminum-Coated Film for LOW-E Glass

LOW-E (Low Emissivity) glass is a type of glass that reduces energy transfer and improves thermal insulation by coating special thin film layers on the glass surface.

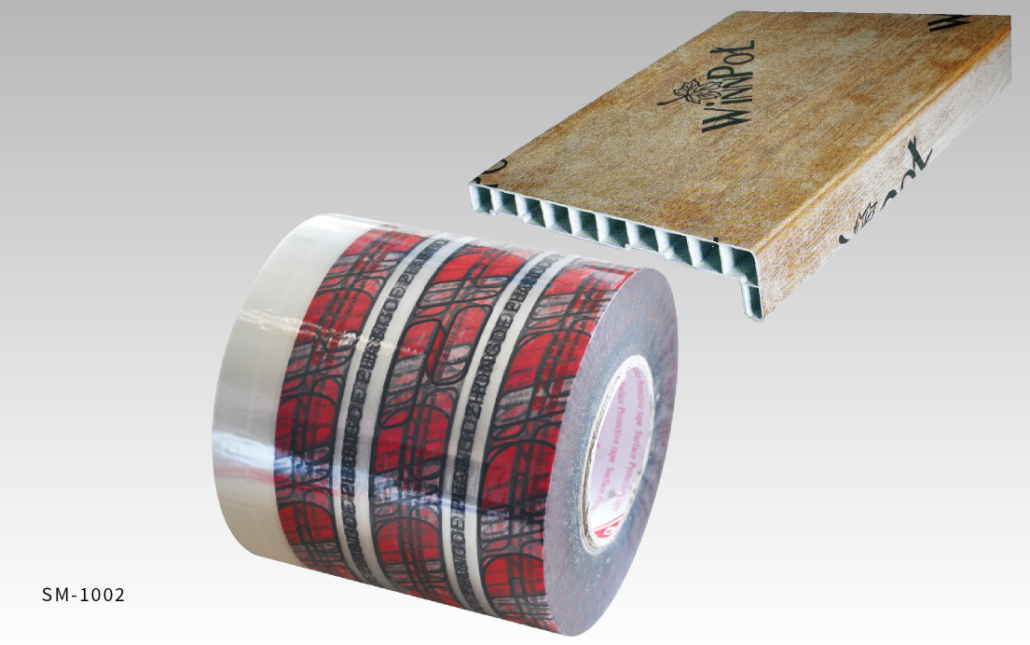

In the manufacturing process of LOW-E glass, two different types of films are commonly involved: regular edge film and aluminum-coated film. They have some differences:

-

Material Composition:

– Regular Edge Film: Regular edge film is typically a transparent and colorless thin film. Its primary function is to reduce the glass’s thermal radiation, thereby improving its insulation performance.

– Aluminum-Coated Film: Aluminum-coated film includes a layer of aluminum, which helps in reflecting thermal radiation, enhancing the glass’s thermal insulation performance.

-

Optical Characteristics:

– Regular Edge Film: The regular edge film tends to have a more transparent appearance on the glass, causing minimal change in the glass’s color or light transmittance.

– Aluminum-Coated Film: Aluminum-coated film may produce some reflective effects on the glass surface, and its metallic properties may create a reflective effect at certain angles.

-

Performance Impact:

– Regular Edge Film: It primarily enhances the glass’s thermal insulation performance by reducing thermal radiation.

– Aluminum-Coated Film: Due to the presence of the aluminum layer, the aluminum-coated film not only reduces thermal radiation but also reflects a portion of solar radiation, improving UV resistance.

-

Production Cost:

– Regular Edge Film: Generally, the production cost of regular edge film is relatively lower.

– Aluminum-Coated Film: Aluminum-coated film often involves depositing aluminum onto the glass surface through a vapor deposition process, which may result in relatively higher production costs.

The choice between regular edge film and aluminum-coated film typically depends on specific application requirements and budget considerations. In some cases, regular edge film may be sufficient to meet insulation requirements, while aluminum-coated film might be chosen for applications requiring higher thermal insulation performance and UV resistance.

If you are interested in our products, please feel free to contact us!

Leave a Reply

Want to join the discussion?Feel free to contribute!