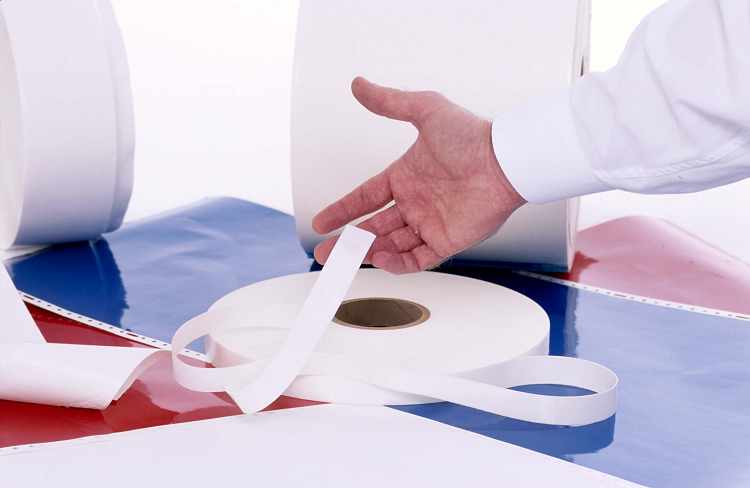

Protective films with release liners will increase costs

Indeed, in some cases, protective films with release liners can increase costs due to the silicone coating on the surface. Here are a few examples:

1. Optics and electronics: In certain high-precision optical and electronic applications, such as optical lenses, displays, or electronic components, protective films with release liners are required. The silicone layer on the release liner ensures complete separation between the protective film and the item’s surface, avoiding any residue or damage. However, the process and material costs of applying the silicone layer are higher due to the demanding requirements and specificity of these applications.

2. Automotive protection: In the automotive industry, it is common practice to use protective films with release liners to protect car paint. The silicone layer on the release liner provides better separation performance to ensure no damage to the car paint surface after removing the protective film. However, applying the silicone layer increases production costs, especially when covering large areas of automotive surfaces.

3. Building glass protection: In the construction industry, it is common to use protective films with release liners to protect glass surfaces. The silicone layer on the release liner ensures no residue or damage is left on the glass surface after removing the protective film. However, applying the silicone layer increases production costs, especially for large glass surfaces.

In these cases, the cost of protective films with release liners is higher due to the special application requirements and high precision protection needs. The silicone coating is applied to ensure complete separation between the protective film and the protected item, preventing any residue or damage. However, in other general applications where protection requirements are less stringent, choosing protective films without release liners may be more cost-effective.

Leave a Reply

Want to join the discussion?Feel free to contribute!