Ten tips to select the right protective films for electronic devices

Electronic devices need high protection from scratches, damage, UV rays, and other issues to enhance their lifespan. A protective film is ideal for electronic devices to prevent unwanted problems. However, electronic industries should understand how to select the right protective films with more attention. This will help them ensure electronic device safety from potential threats.

How do you pick the right protective films for electronic devices?

- Evaluating the device type

Electronic devices involve different types, and a manufacturer should evaluate certain things while selecting a protective film. They include the device type, size of the device, and screen type. This is because different devices have different screen types and sizes. For instance, television sets require custom-made protective films, and gadgets need a full-screen or non-full-screen type.

- Selecting the best material and craftsmanship

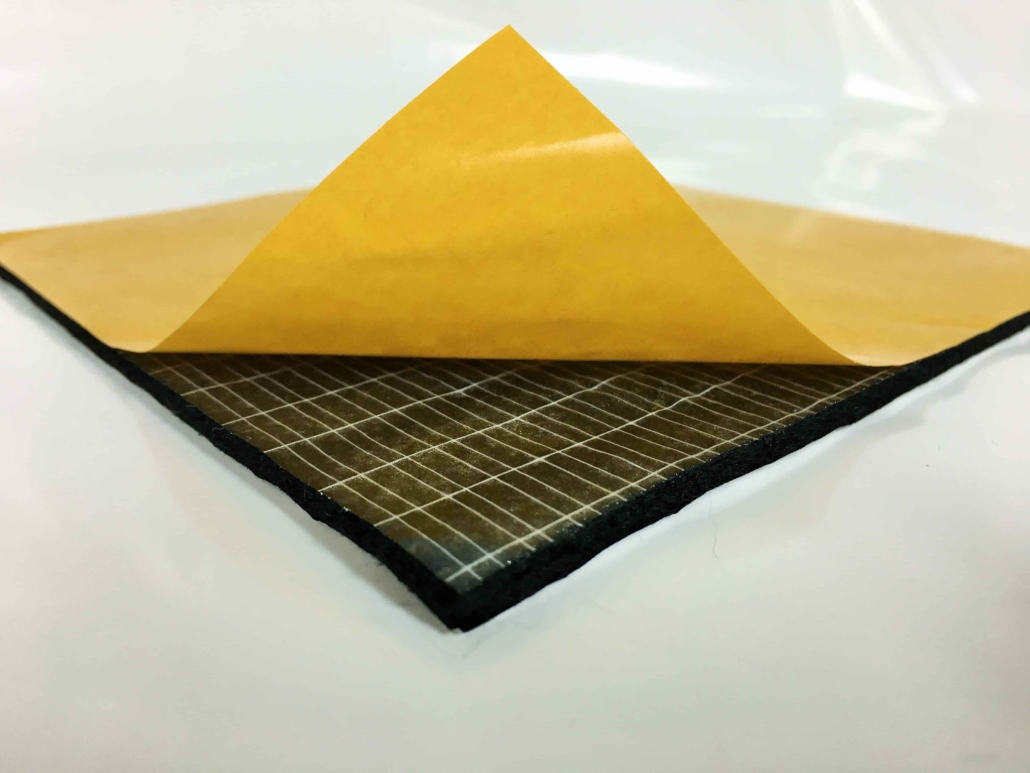

Electronic manufacturing industries should select the best protective films that suit their applications. Some common protective films that are available on the market include PET, tempered glass, TPU, etc. A manufacturer should identify the right material for a device to enhance its durability.

- Ease of application

Ease of application is an important factor when selecting protective films for electronic devices. While self-applied films are easy to install, some films need professional installation. The self-applied films are the right choice for industries to overcome problems during the installation process.

- Level of protection

Electronic industries should consider the level of protection properly because it may vary depending on the usage. They should select a film that offers the maximum protection against environmental impact and other problems.

- Touch sensitivity

Touch sensitivity is another factor to keep in mind when selecting a protective film, and the industry should check the ratings. Some protective films provide ways to maintain the touch sensitivity of electronic devices.

- Light transmission and clarity

A protective film should ensure clear visibility on a device’s screen without impurities or other problems. Hence, the electronic manufacturing industries should give more importance to light transmission and clarity.

- Reputation of a manufacturer or supplier

Nowadays, many manufacturers offer protective films for the electronic industry that cater to their needs. At the same time, not all of them are the same, and customers should check the reputation of a manufacturer or supplier. Electronic industries should compare the reviews of protective film manufacturers to get more ideas.

- Quality

The electronics industry should evaluate the quality of protective films before investing money in them. They should ask for samples from a manufacturer or supplier to know the quality of the films.

- Price

While buying protective films, the electronic manufacturing industry should consider the prices in detail. Since the prices may vary from one manufacturer to another, knowing the costs enables industries to make informed decisions.

- Storage requirements

Protective films should comply with certain requirements in the storage process. Electronic manufacturing units should know the temperature and other things to keep them in perfect condition for a long time.

Leave a Reply

Want to join the discussion?Feel free to contribute!