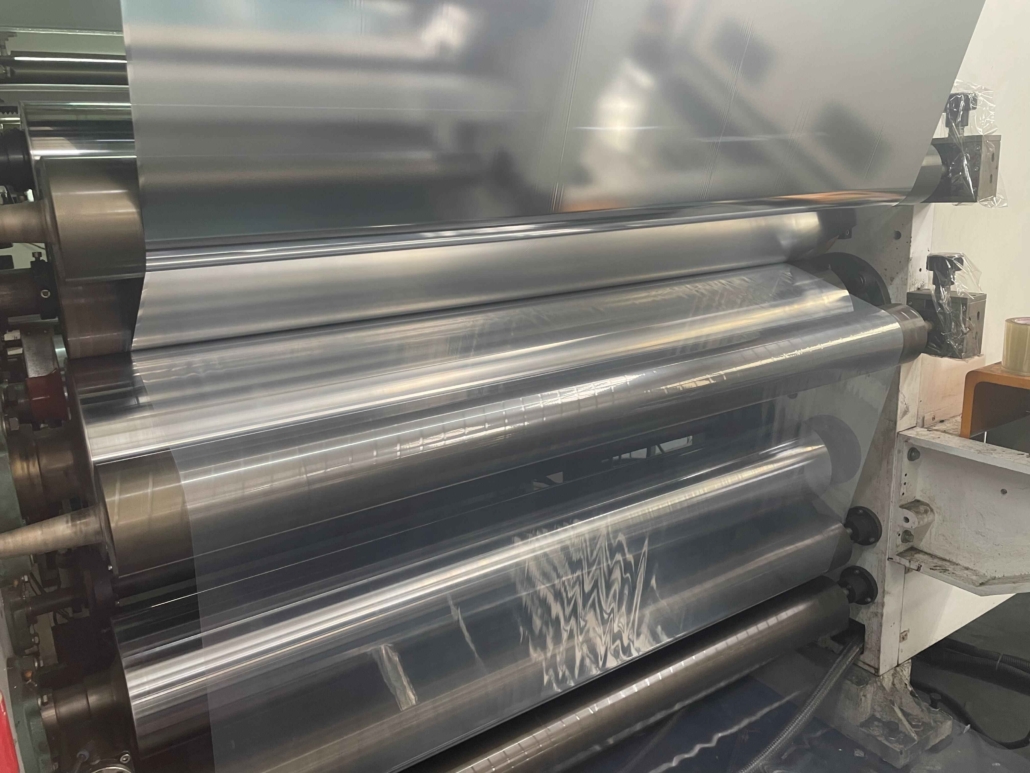

How to tear the protective film to prevent the film from breaking

When tearing the protective film, ensure that the proper methods and techniques are followed to reduce the risk of film fragmentation.

Here are some tips to help prevent the film from breaking:

- Slow and steady tearing: do not tear the protective film too hastily or too forcefully. A slow and steady force is used to prevent the film from being over-stretched and damaged.

- Pull at an Angle: If possible, try to pull the protective film at an Angle rather than vertically. This reduces stress concentration on the membrane surface and reduces the risk of fragmentation.

- Use a nail or tool: Use a nail or an appropriate tool, such as a fine-pointed plastic scraper, to gently push away one corner of the protective film. This creates a gap at the edge, which is easy to start tearing, reducing the stretching and twisting of the film.

- Pre-heating: If in a cold environment, you can consider using a slight heat source, such as a hair dryer, to pre-heat the protective film. Warm membranes stretch more easily, reducing the risk of fragmentation.

- Wet protective film: Gently apply a small amount of water or wet paper towel on the surface of the protective film, sometimes can reduce the viscosity of the film, making it easier to tear.

- Find the tear point: Sometimes, the protective film may have a designated tear point, and by finding this point, you can more easily start tearing.

- Avoid sudden pulling: Avoid sudden pulling of the protective film, which may lead to sudden tearing of the film.

- Practice and be careful: If you are tearing the protective film for the first time, you can practice in a less important place first to familiarize yourself with the feeling and technique of tearing.

In short, care and patience are the keys when pulling the protective film. Following the above recommendations to tear the protective film with the appropriate method and force can reduce the risk of fragmentation and maintain the integrity of the film. If the protective film breaks, it may cause difficulty in removing, adhesive failure, or affect the cleanliness of the protected surface.

If you are interested in our products, please contact us!

Leave a Reply

Want to join the discussion?Feel free to contribute!