Pressure sensitive adhesives that can be vulcanized by heat

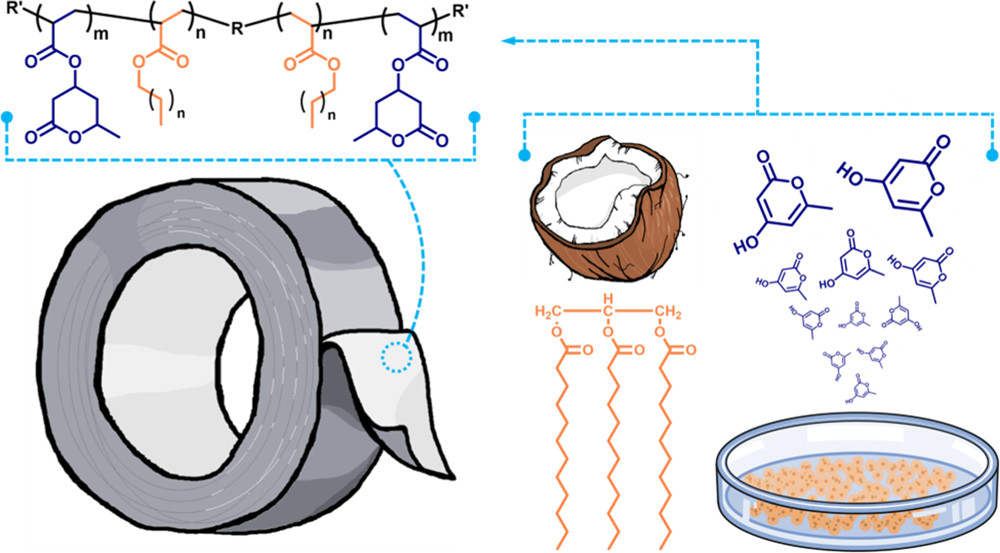

Pressure-sensitive tapes that can be thermally vulcanized are known. Patent EP 877 069 A describes a pressure-sensitive adhesive sheet based on a thermovulcanized polyester rubber. The disadvantage is a specific aspect of the manufacturing operation: the polyester reaction is initiated with a liquid starting material. By gradually cross-linking the reaction, the polymer is formed only during the coating period.

This has the following disadvantage: the coating speed is limited because the reaction mixture coated on the stripped liner or the carrier material cannot be wound, or at least cannot be wound at a constant layer thickness, while it is still liquid or paste. Only solid polymer films can be wound with constant layer thickness. Therefore, the reaction product cannot be wound until the reaction mixture is solidified. The coating speed must be set to a correspondingly slow rate. Moreover, polyester rubber has the potential disadvantage of easy hydrolysis and splitting.

The rubber described in DE 38 30 895 A consists of at least two starting polymers chemically connected to each other by an ester group and at least one of which is unsaturated in the alene group.

The rubber has in principle disadvantages similar to the possible base elastomer of a pressure-sensitive tape that can be thermally vulcanized. The same applies to liquid or spreadable (spreadable) vulcanizable rubber mixtures described in EP 0 356 715 A, which are based on polyester polymers, at least one of which is unsaturated in the genus alene. Polybutadiene-polyurethane pressure sensitive adhesive is described in JP 59230076A.

Polybutadiene-polyols with 2.2-2.4 functionalities react with polyisocyanates at a NCO/OH ratio of 0.2-0.65 to form polyols with a molar mass of 5000 to 30000 and a functionalities of 2.2-2.4. The polyol was then mixed with polyisocyanate at a NCO/OH ratio of 0.6-1.0 and reacted accordingly to form the desired product. There is no indication of a base polymer that may be used as a pressure sensitive adhesive that can be thermally vulcanized, which will be prepared solvent-free in the mixing and coating operation.

For such use, the pressure-sensitive adhesive will have the disadvantages of being cross-linked initially and therefore unsuitable for coating operations, or being liquid at room temperature and therefore unsuitable as a base elastomer for coating operations where very low NCO/OH ratios are operated within the limits specified in the patent and therefore no cross-linking occurs.

Leave a Reply

Want to join the discussion?Feel free to contribute!