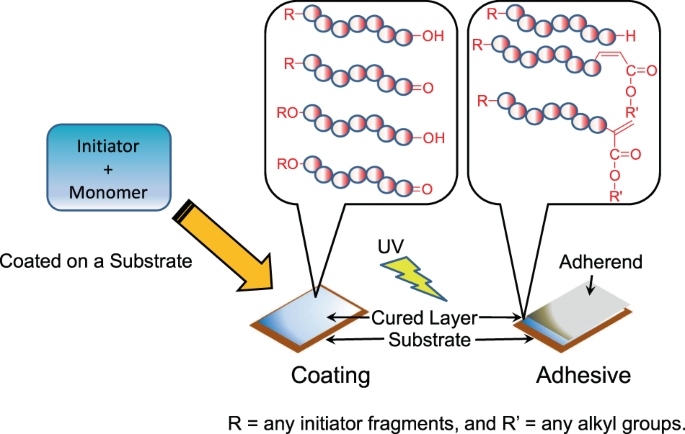

Preparation method of UV-curable pressure-sensitive adhesive

Example 1: 50 parts of methyl hydrogen silicone oil with hydrogen content of 3mmol/g and viscosity of 100cp at 25℃, 60 parts of toluene and 0.5 parts of Karstedt catalyst were added to the reactor equipped with mechanical stirring, thermometer, reflux condensation tube, drip funnel and nitrogen protection device. The temperature was heated to 120℃ while stirring. Then 20 parts of vinyltriethoxy-silane was slowly added to the solution under nitrogen protection for 20min. After the drip was completed, 3 parts of allyl methacrylate was slowly added to the solution for 5min. After the reaction was completed, toluene was removed by vacuum to obtain modified polysiloxane. Then take another reaction kettle equipped with mechanical stirring and nitrogen protection device, add modified polysiloxane, 35 parts pentaerythritol triacrylate, 30 parts isobornyl acrylate, 25 parts epoxy acrylate resin, 5 parts benzoin dimethyl ether and 2 parts of antifoaming agent, stir and mix evenly, and evenly coat the prepared adhesive on the polyester film. At the wavelength of ultraviolet light of 400nm, curing 40s.

Embodiment 2: The difference between this embodiment and Embodiment 1 is that the amount of allyl methacrylate is 2 parts and the rest are the same as in Embodiment 1.

Embodiment 3: The difference between this embodiment and Embodiment 1 is that the amount of allyl methacrylate is 1 part and the rest is the same as in Embodiment 1.

Embodiment 4: The difference between this embodiment and Embodiment 1 is that the amount of vinyl triethoxy-silane is 18 parts and the rest are the same as in Embodiment 1.

Embodiment 5: The difference between this embodiment and Embodiment 1 is that 16 parts of vinyl triethoxy-silane are used and the rest are the same as in Embodiment 1.

Leave a Reply

Want to join the discussion?Feel free to contribute!