Nine tips to follow when buying PE protective films for die-cutting purposes

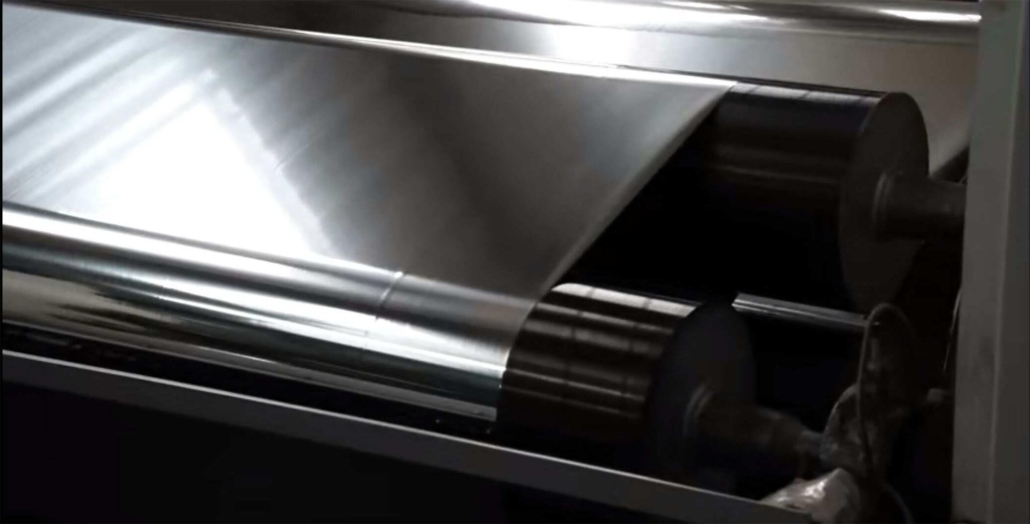

Die-cutting is a procedure followed in the manufacturing process to get the desired shape and size of a product. Manufacturing units use different types of products in the process to ensure the best results. However, some of them may not be aware of polyethylene (PE) protective films because they offer several advantages. On the other hand, buying PE protective films for die-cutting should meet certain requirements that help obtain the desired outcomes.

What are the steps to follow when buying PE protective films for die-cutting?

- Evaluating the transparency

Before buying PE protective films for die-cutting, users should check their transparency with more attention. It is difficult to check the transparency with the naked eye, and they can use optical instruments for this purpose. One can check the whiteness of a film by placing it in the middle of a desktop. The next step is to open a Word document to determine the whiteness of the blank document in different areas, and films that have the brightest levels are the best.

- Checking the fogging

Fogging is another factor to consider when buying PE protective films for die-cutting that help gain more advantages. Manufacturers can apply some techniques to check fogging with high efficiency. They should make sure that the films are anti-fogging and enhance visual clarity.

- Knowing the static electricity

Those who want to use PE protective films for die-cutting applications should evaluate the static electricity with certain experiments. By doing this, they can make informed decisions that help improve the production process.

- Estimating the scratch resistance

Users should consider estimating the scratch resistance of PE protective films during the die-cutting process. They can use a 3H pencil for this purpose, which helps determine the resistance effectively.

- Anti-finger point

The screens of several products are becoming larger over time, and PE protective films should have an anti-finger point feature. Manufacturers should check whether they provide the facility during the die-cutting process.

- Quality

Quality is an important factor to keep in mind while purchasing PE protective films for die-cutting applications. Not all films are the same, and users should check the quality using certain techniques. Selecting the best PE protective films allows industries to overcome unwanted problems.

- Strength

Manufacturers should evaluate the strength of PE protective films because they play a key role in preventing damage during the cutting process. They can compare the strengths of films before buying them, which helps them select them based on their requirements. Furthermore, users can get more insights into products to proceed further.

- Identifying a reliable manufacturer or supplier

Anyone who wants to buy high-quality PE protective films should consider choosing a reliable manufacturer or supplier on the market. They should make a detailed study of various manufacturers online to select the right one.

- Cost

The cost of PE protective films may vary from one manufacturer to another in a given location. Therefore, customers should compare them to order products that suit their budget and needs.

Leave a Reply

Want to join the discussion?Feel free to contribute!