Low-E Glass Protective Film

Low emissivity (Low-E) glass is one of the most popular and versatile building materials today, due to its excellent heat insulation effect and good light transmittance. This is where Low-E glass coatings come into play. This coating is comprised of extremely thin layers of silver or other metal compound materials. By reflecting the interior temperatures back inside, this coating achieves the effect of keeping the room warm or cold. While before processing into the insulating glass, the edge coating of off-line Low-E glass, which is processed by the method of Magnetron Sputter Vacuum Deposition (MSVD) is easily oxidized. This oxidization will affect the follow-up processing.

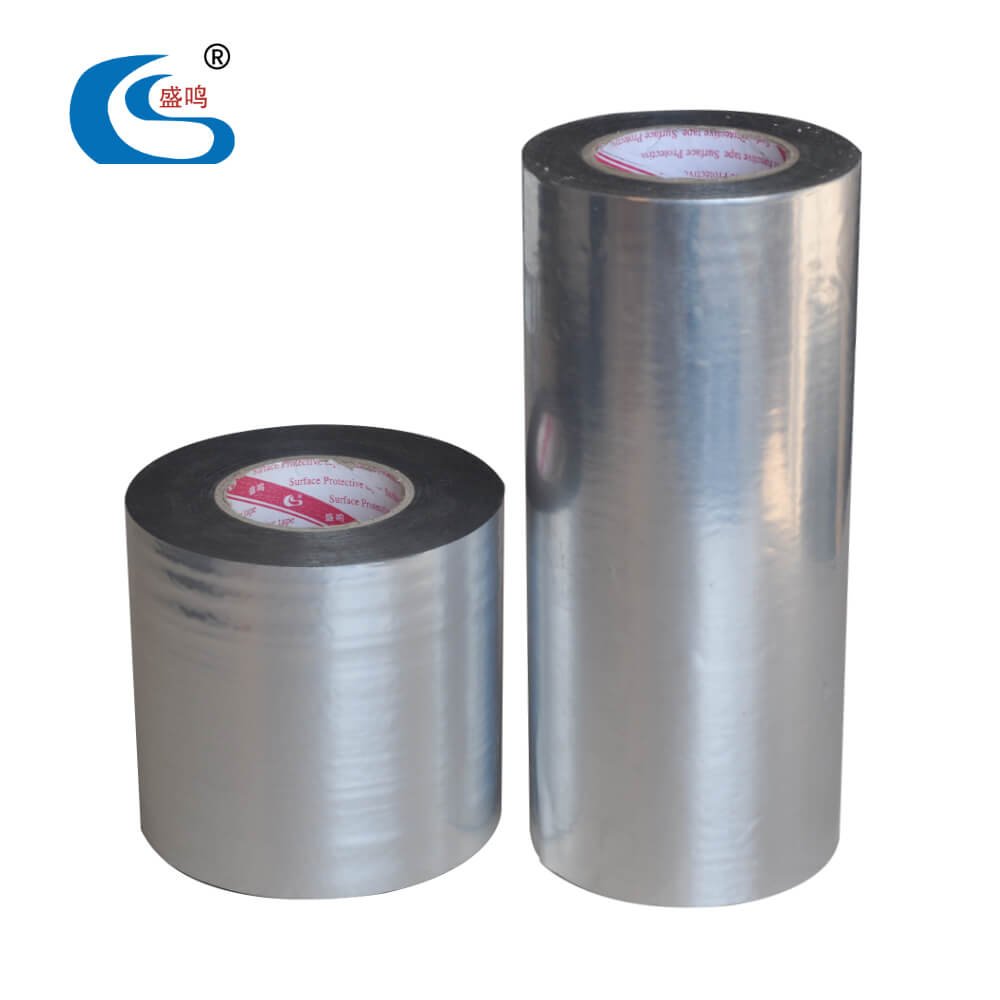

Our Low-E protective film is developed to play the role of sealing protection and finally to achieve anti-oxidation protection to offline Low-E glass. On the basis of the previous two products, through continuous breakthroughs and practice, the third generation of glass edge sealing film developed by our company has excellent puncture resistance, extensibility as well as sealing performance. The excellent anti-puncture performance can effectively avoid glass edges from cutting off the protective film causing air leaking. The suitable extensibility makes the protective film tightly affixed on Low-E glass during transportation, completely cutting off the contact between air, water and the Low-E coating, achieving anti-oxidation protection.

Compared with conventional glass protective film, the usage of our protective film for Low-E glass is quite different. It is used around the Low-E glass to prevent silver coating oxidization. It has a matte appearance and the logo and specification can be customized. With reasonable prices and amazing sealing performance, our protective tape for low radiation glass are very popular in domestic top 10 well-known glass enterprises.