How to prepare an aqueous acrylic adhesive with high adhesion value and low residual value

A pre-emulsion containing 28 parts BA, 22 parts EHA, 1.5 parts AA, 1.0 part HEA, 0.5 parts AM, 0.6 parts Mon0 pol NP1018, 0.2 parts SE-10N, and 20 parts deionized water was prepared in a glass or stainless steel reactor.

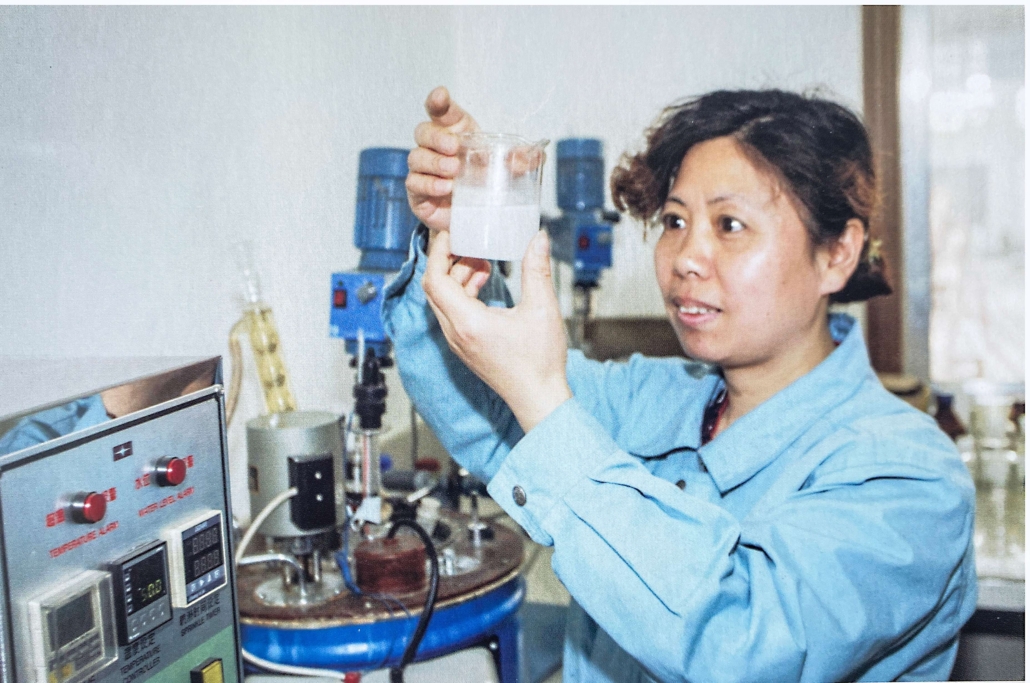

To the polymerization reactor equipped with a reflux condenser, thermometer, and stirrer, 10% of the prepared pre-emulsion, 5 parts of deionized water, and 5 parts of polyester resin AQ1045 (Eastman Chemical Co.) were added, followed by thorough stirring of the resulting mixture at 75°C. To this mixture, the remaining 90% of the above pre-emulsion was slowly added over a period of 5 hours.

The remaining 90% of the above pre-emulsion and an initiator solution containing 15.85 parts of deionized water, 03 parts of ammonium persulfate, and 0.05 parts of sodium phosphate was slowly added to this mixture over 5 hours for the polymerization reaction. After all the reactants were added, the temperature was raised to 80°C and the reaction mixture was reacted for another 1 hour.

After cooling, the pH of the mixture was adjusted to 5.5-6.0 using an 8% solution of zinc ammonium bicarbonate (Billion AB) prepared with ammonia, zinc oxide, and ammonium bicarbonate, and then the viscosity of the mixture was adjusted to 3500 cps using a tackifier to produce an aqueous acrylic adhesive.

The aqueous acrylic adhesive is applied to one side of a PET film as described above, and the volatiles is removed from the adhesive in a drying chamber to produce an adhesive layer. The tape was prepared by attaching a glass wool mesh to the adhesive layer and reapplying the aqueous adhesive to the glass wool mesh attached to the adhesive layer to form another adhesive layer, resulting in an adhesive strength value of 790 g/26 mm and a residual value of 3.0%.

Leave a Reply

Want to join the discussion?Feel free to contribute!