Molecular defoamer suitable for water-based pressure sensitive adhesive

What is defoamer?

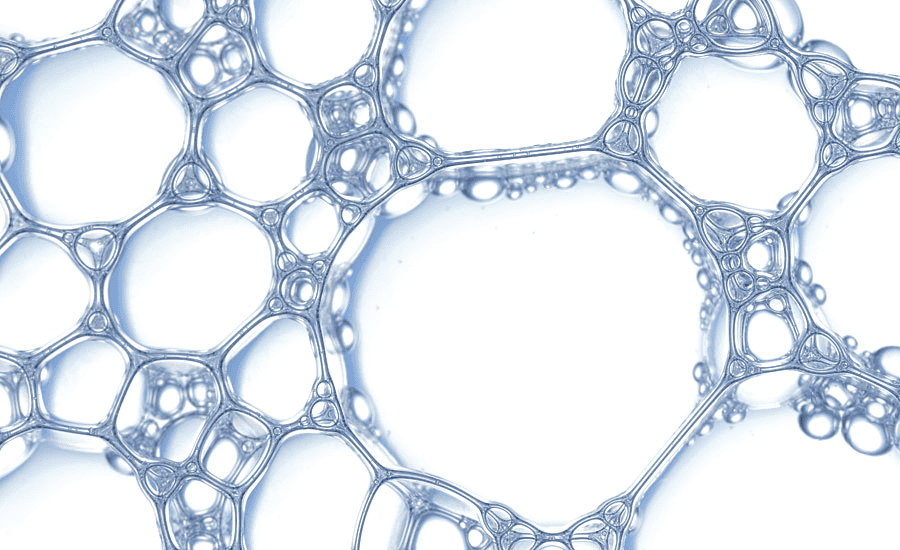

Defoamer is a substance with low surface tension and high surface activity, which can inhibit foam in liquid, that is to say, defoamer can reduce the surface tension of water, solution, suspension, etc., to prevent foam from producing or making the original foam.

What is Long-time defoaming?

Long-time defoaming is also known as defoaming, the length of defoaming time is the main symbol of the quality of the defoaming agent. In most cases, the use of a defoamer is to take advantage of its anti-bubble properties, rather than the initial defoamer. Defoaming and defoaming are relative, and the relative defoaming performance of products with good defoaming performance will be poor. In practical application, it depends on the specific situation. Therefore, from the point of view of the defoaming effect, the defoaming agent includes the defoaming agent, defoaming agent, and defoaming agent, which are called the defoaming agent.

Why need to use a defoaming agent?

Some components of water-based adhesives are easy to produce bubbles and have a stable and lasting tendency. In addition, the production of rapid mixing and the use of high-speed brushing construction will also contribute to the generation of foam, so that production can not proceed normally, and affect the quality of the product. The formation of foam in the production and coating of tape to great difficulties, and make the rubber layer appear as pores, affecting the product outside and adhesive properties, so we must try to destroy the foam or prevent the generation of foam, quite effective method is to use a defoaming agent.

Two main categories of defoamer

There are many varieties of defoamer used in the water-based adhesive industry, but there are mainly two categories: polysiloxane defoamer and non-siloxane defoamer.

Polysiloxane defoaming agents have strong defoaming and anti-foaming abilities and are widely used in the coating industry. In the water-based adhesive industry, especially the emulsion types low viscosity systems, such as film adhesive, and pressure sensitive adhesive, it is very easy to cause shrinkage and fisheye problems. In addition, after the emulsion film formation, due to the surface migration of silane, it will cause a decline in the later bonding strength and affect the bonding effect, so it is rarely used.

In the water-based pressure sensitive adhesive and coated adhesive industry is generally used in mineral oil defoamer. It is mainly composed of mineral oil, hydrophobic particles, low carbon alcohol, emulsifier, and so on. The quality of this kind of product is easily affected by the brand and batch difference of mineral oil. As the whole system is thermodynamically unstable, it is easy to stratify and provide defoaming effect mainly by dispersing in the emulsion.

Affected by small molecular additives and surfactants in emulsion, mineral oil defoaming agent is easy to float oil in these systems, which will cause a serious decrease in defoaming effect. The uneven distribution of mineral oil will also affect the coating effect, which brings great trouble to our production and application.

Smprotectivefilm–Wuxi Changsheng Adhesive Products Co., LTD.

Wuxi Changsheng Adhesive Products Co., LTD., the company specializes in R & D, production, and sales of pressure-sensitive adhesive series products, if you need to consult, you are welcome to inquire or Email.

Leave a Reply

Want to join the discussion?Feel free to contribute!