What are the ways to deal with PE protective film waste?

PE protective film is widely used for various applications to protect surfaces from potential threats. However, it may cause substantial waste while being used, which needs more attention. It is wise to know how to deal with the PE protective film waste properly, which helps protect the environment. Furthermore, industries can focus more on enhancing the production process, which gives ways to achieve better results. Implementing effective recycling and disposal strategies enables industries to maintain their surroundings in a clean state for a long time.

How to manage PE protective film waste?

- Organizing a waste audit

Before using PE protective films, industries should consider organizing a waste audit to evaluate waste generation patterns. Moreover, they should identify the areas that need improvement.

A waste audit allows industries to get more information about various things that help make the best decisions. Aside from that, it provides methods to develop effective waste reduction strategies that address the problems in specific areas.

- Choosing high-quality film

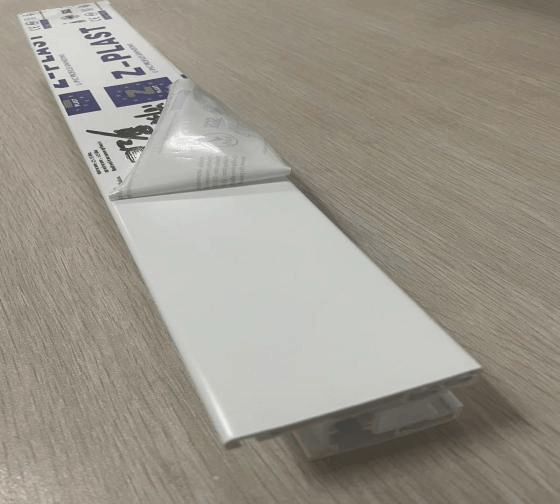

Using high-quality PE protective films allows industries to improve durability and reduce damage during transit. Users should know the options that are available for their specific needs and make sure that they comply with industry standards. They can assess the quality of films before purchasing them from a manufacturer or supplier.

- Applying pre-stretching technology

Applying pre-stretching technology can reduce the amount of stretch film used, which doesn’t affect product protection. Another advantage of this technology is that it provides ways to reduce manual handling injuries to a greater extent.

- Using the right amount of film

Overusing PE protective films can lead to excessive waste, and industries should evaluate the amount needed for the goods during transportation. Implementing the correct wrapping techniques and picking the films with appropriate thicknesses can help reduce waste.

- Knowing more about recycling programs

Recycling is one of the ways to reduce PE protective film waste, and industries should know more about recycling programs from different sources. Besides, companies should seek support from their waste management provider to choose proper recycling techniques that will work well during the manufacturing process. Many companies nowadays offer eco-friendly PE protective films that are tailored to the specific needs of industries.

- Creating awareness among employees

Companies should create awareness about the reduction of waste among employees in several ways that help overcome unwanted problems. Also, employees will follow the best practices while using PE protective films, which provide methods to achieve the desired outcomes.

- Implementing proper packaging methods

Proper packaging methods can reduce the waste of PE protective films, and companies should implement them to lower unwanted problems. Furthermore, they provide more protection for products to reduce damage.

Where to buy eco-friendly PE protective films?

Anyone who wants to buy eco-friendly PE protective films should select a reputed supplier or manufacturer in the market. Wuxi Changsheng is a leading producer of PE films that offers high-quality products at an affordable price. They are eco-friendly and allow industries to avoid environmental pollution and other issues.

Leave a Reply

Want to join the discussion?Feel free to contribute!