We are a skilled PE protection film manufacturer committed to producing various types of protective film. Each blemish or scratch can reduce the product’s value and raise your costs for replacement or repair. We provide temporary surface protection for wood, carpets, aluminum, stainless steel, and more. Learn more about our available products below:

Available PE Protective Films

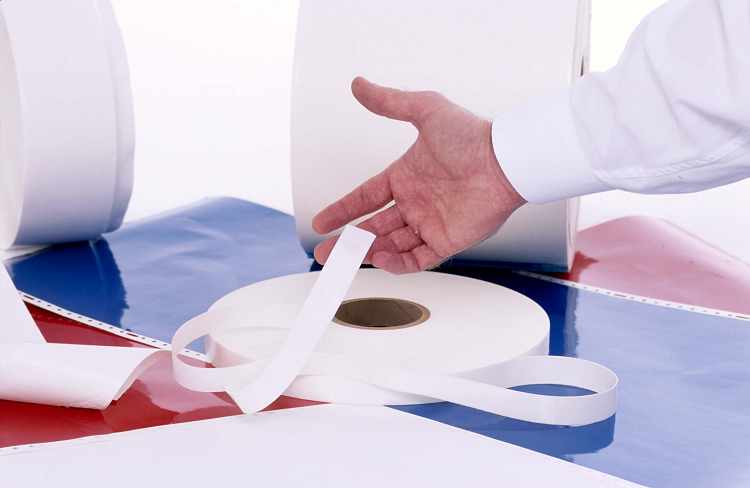

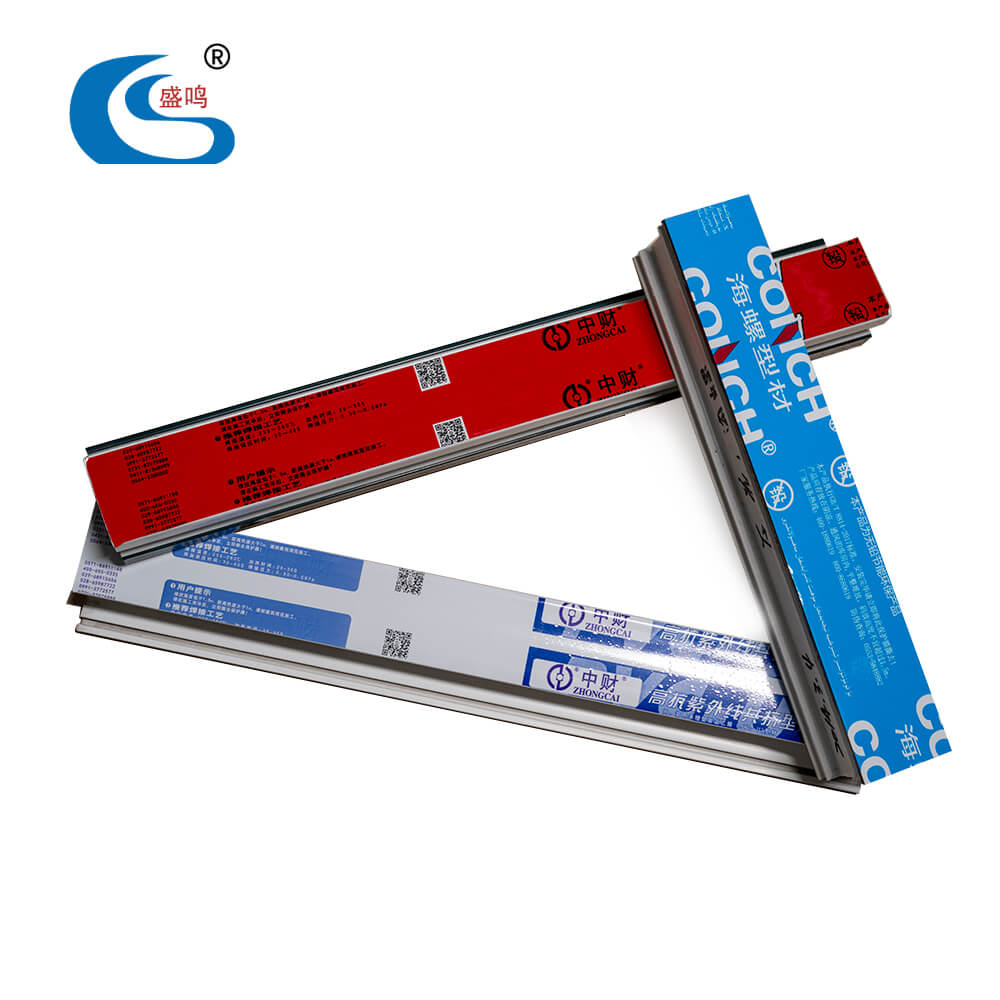

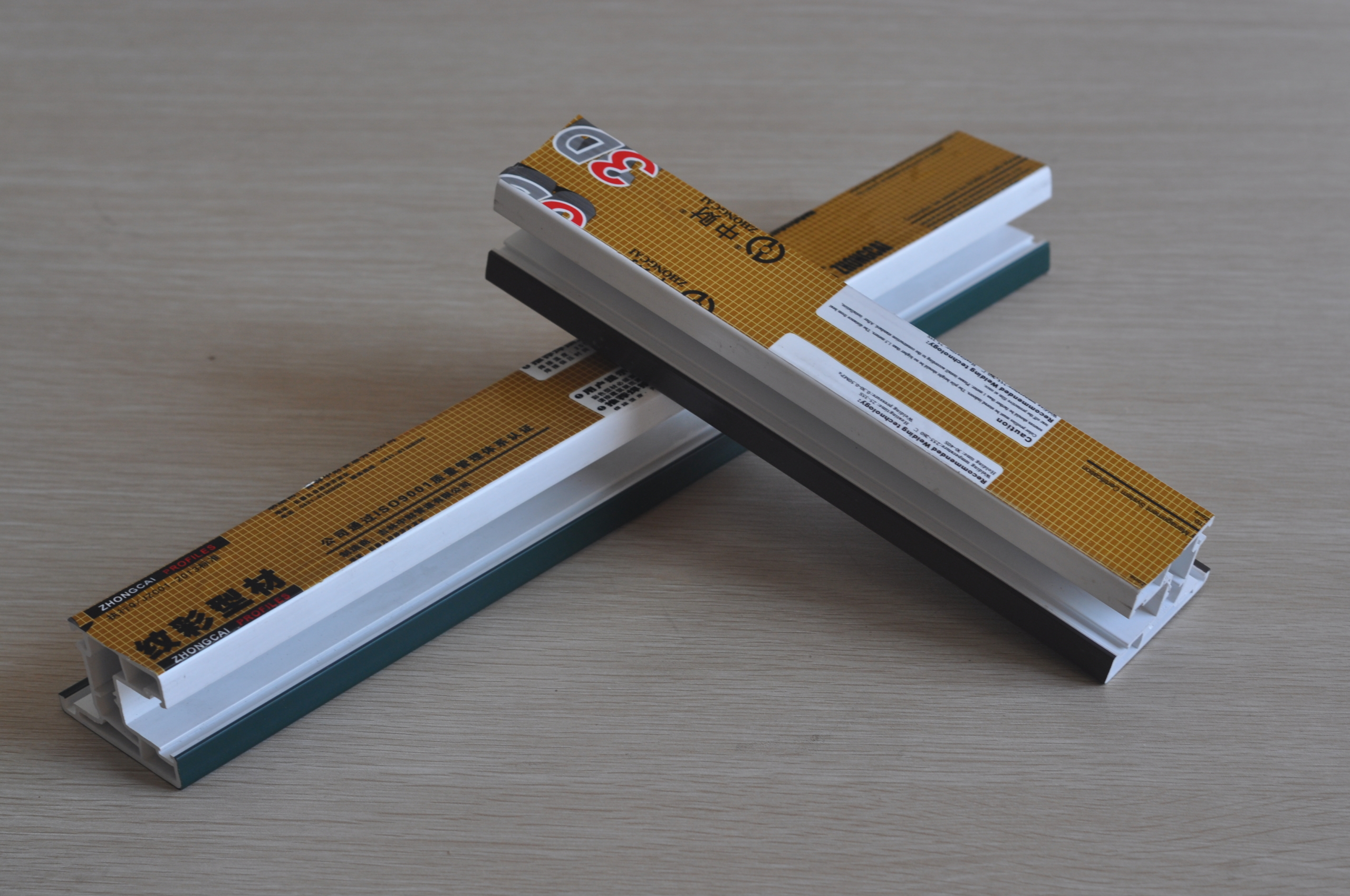

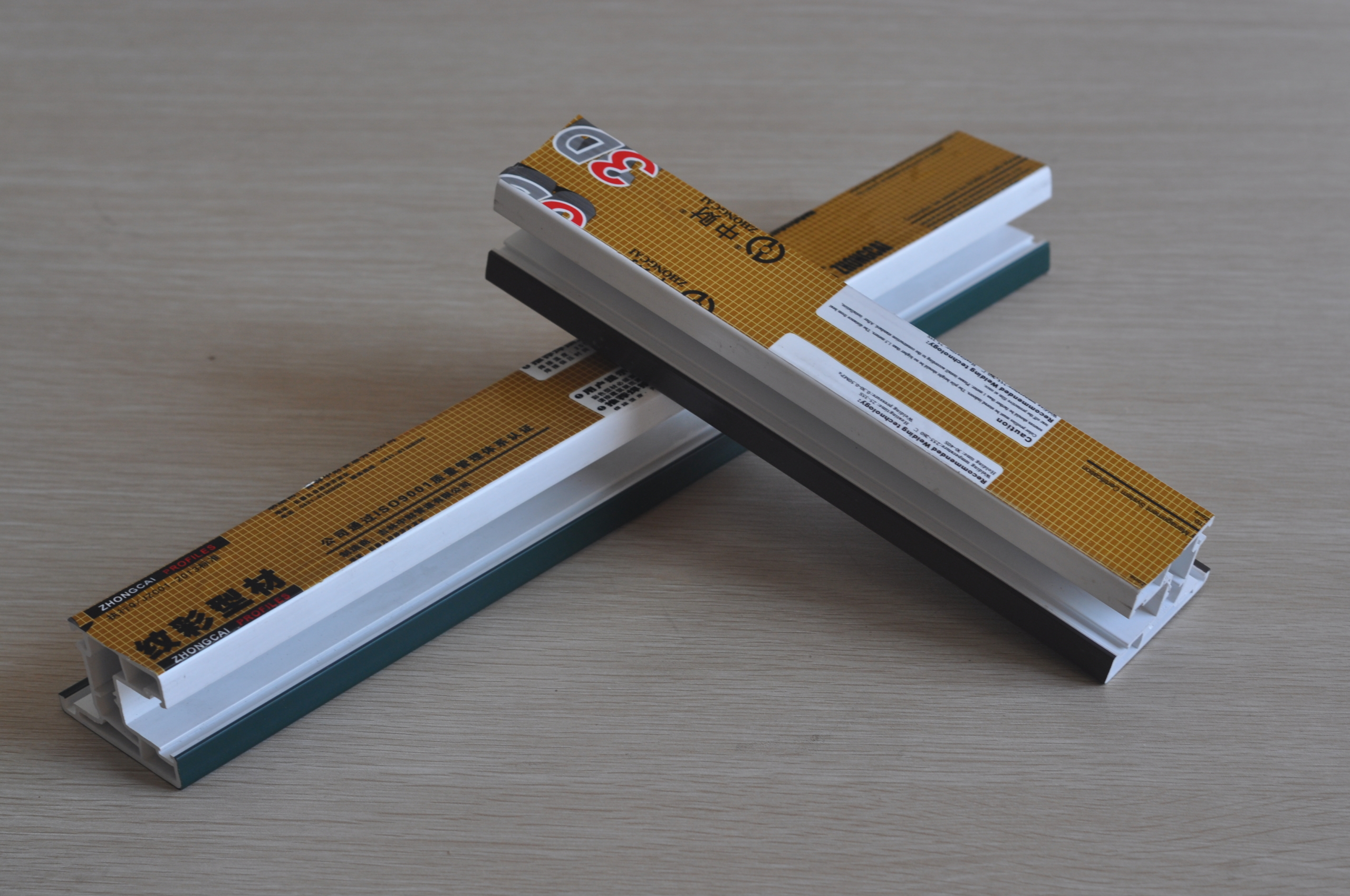

Medium adhesion PE protective films for aluminum profile

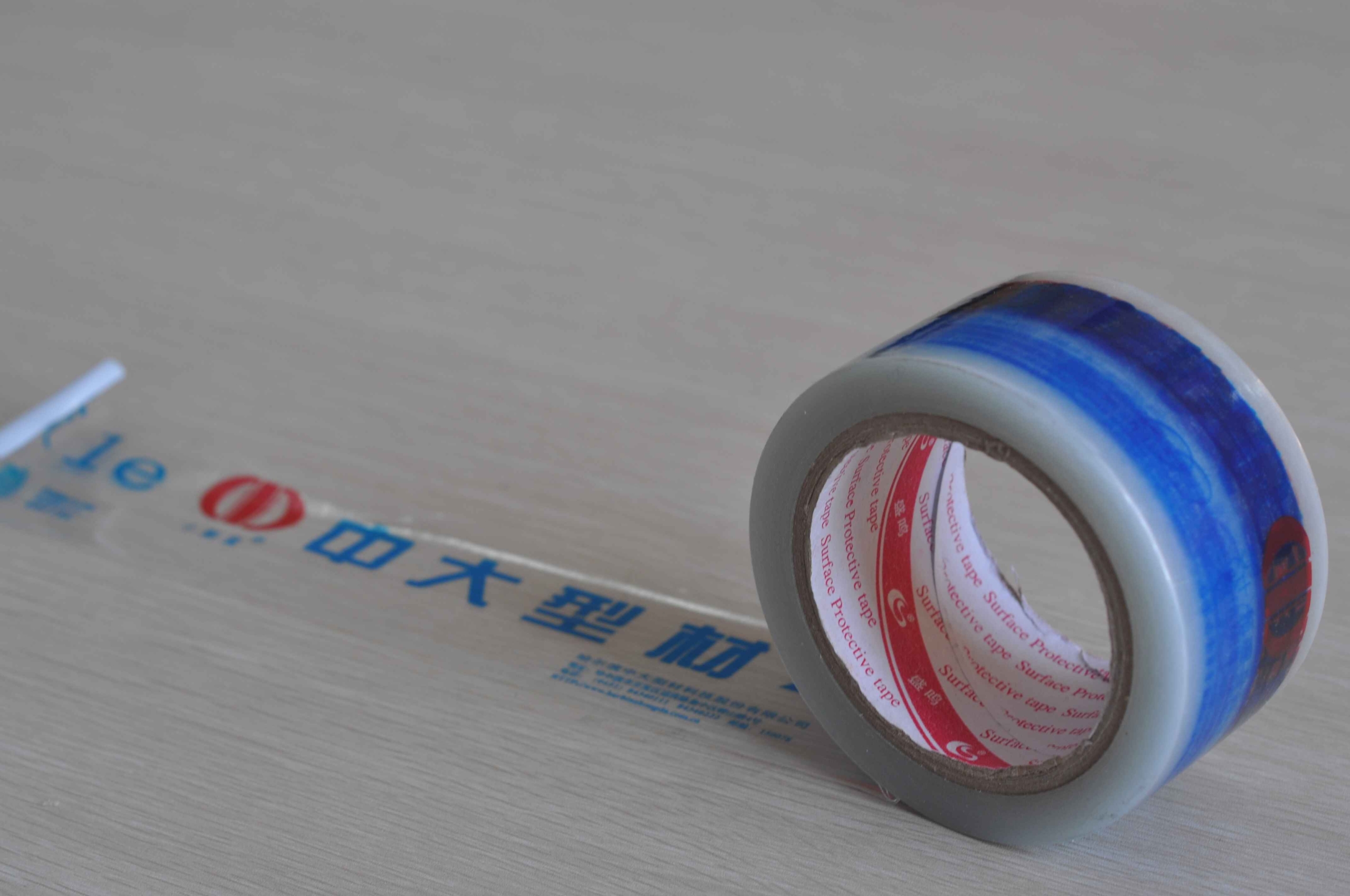

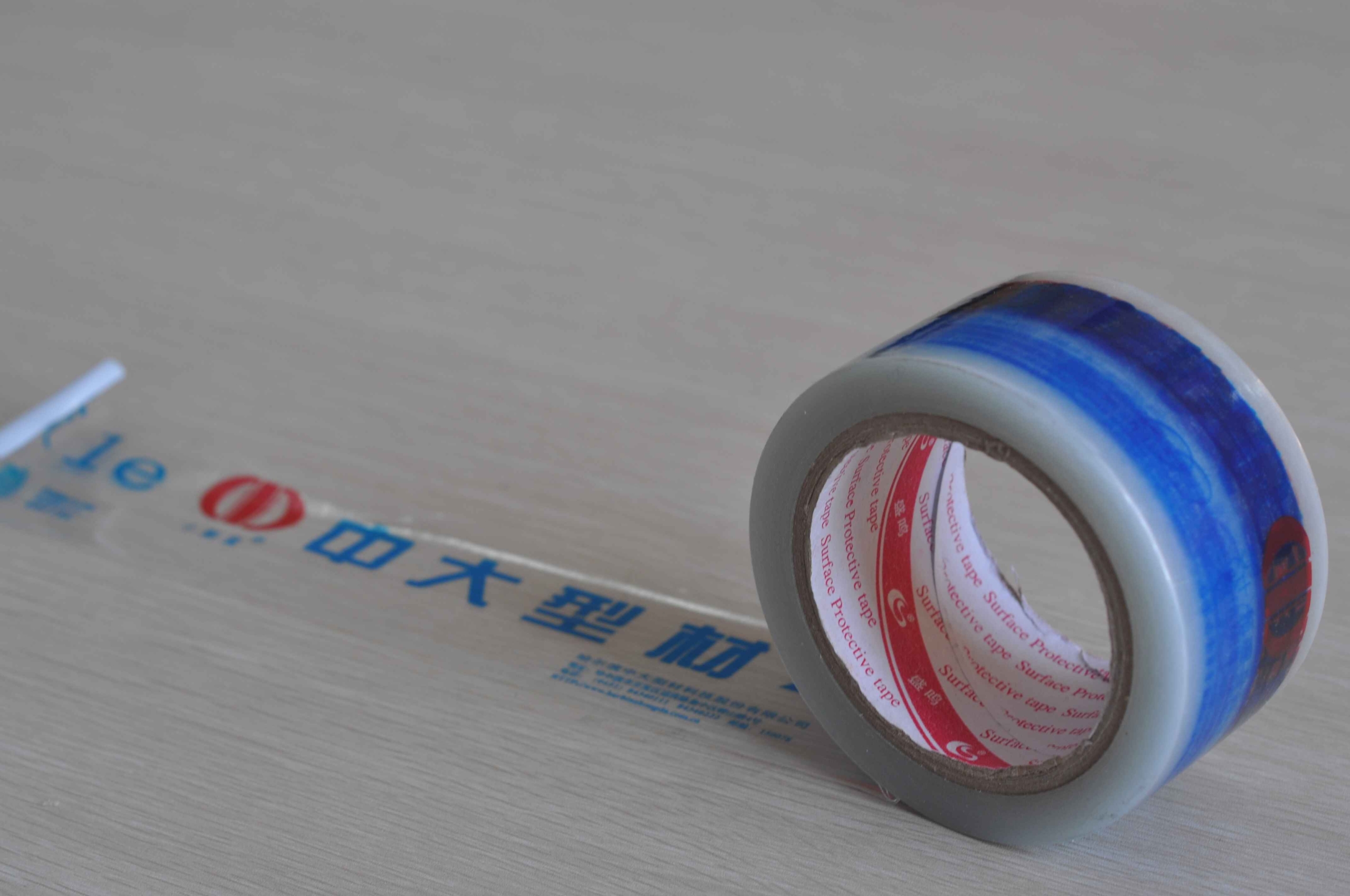

Our medium-adhesion PE protection film offers steady adhesion, simple usage, and no trace. The aluminum surfaces can be shielded efficiently from debris, scratches, and damage during manufacture, warehousing, transit, and assembly. It is more appropriate for designs with somewhat rough surfaces and stronger adhesion needs, like the alumina profile.

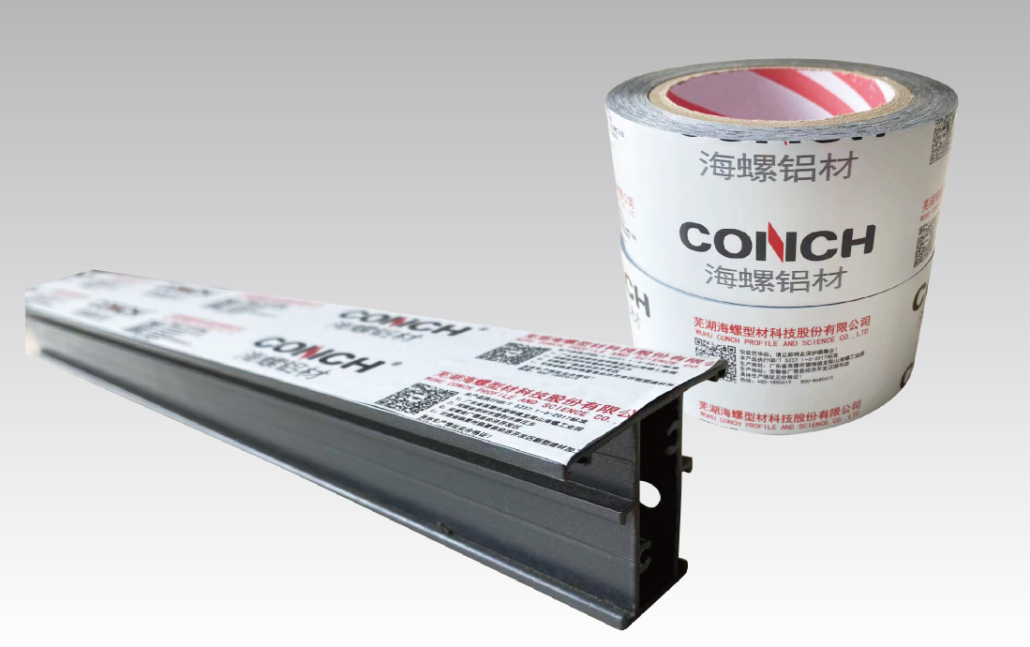

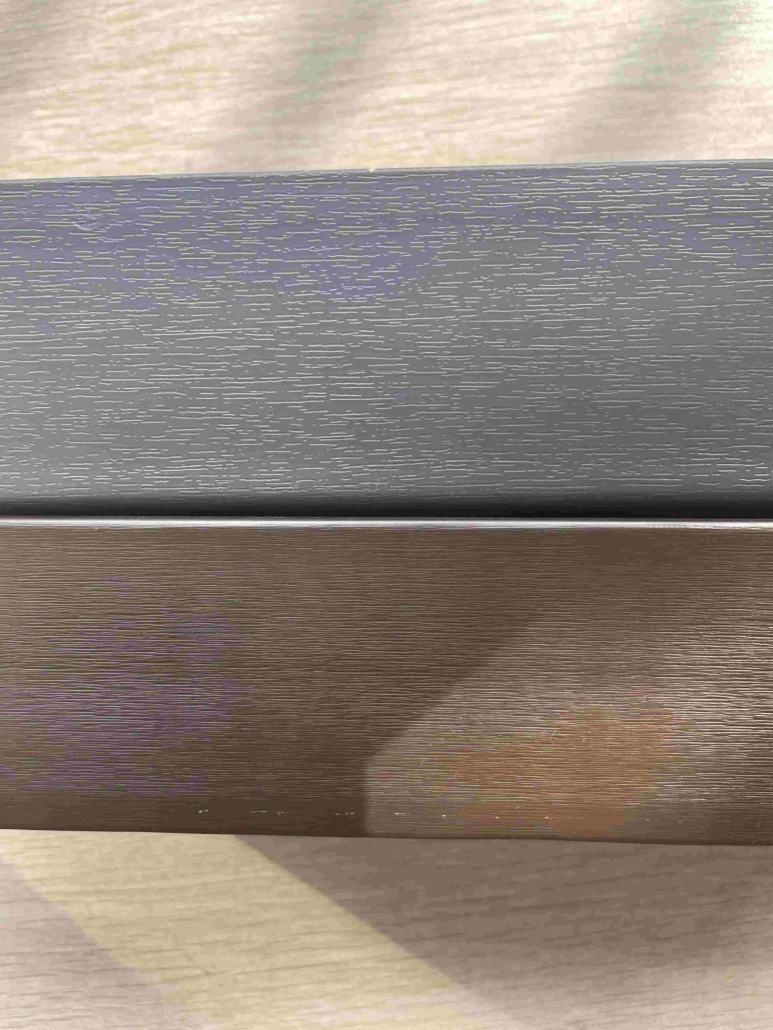

PE protective film for aluminum profiles with smooth surfaces

The entire production, shipping, or installation process has several possible risks. Dust and grime may contaminate it, as can sprays and markings, and harsh handling can damage it. You can prevent these issues by using our PE protection film.

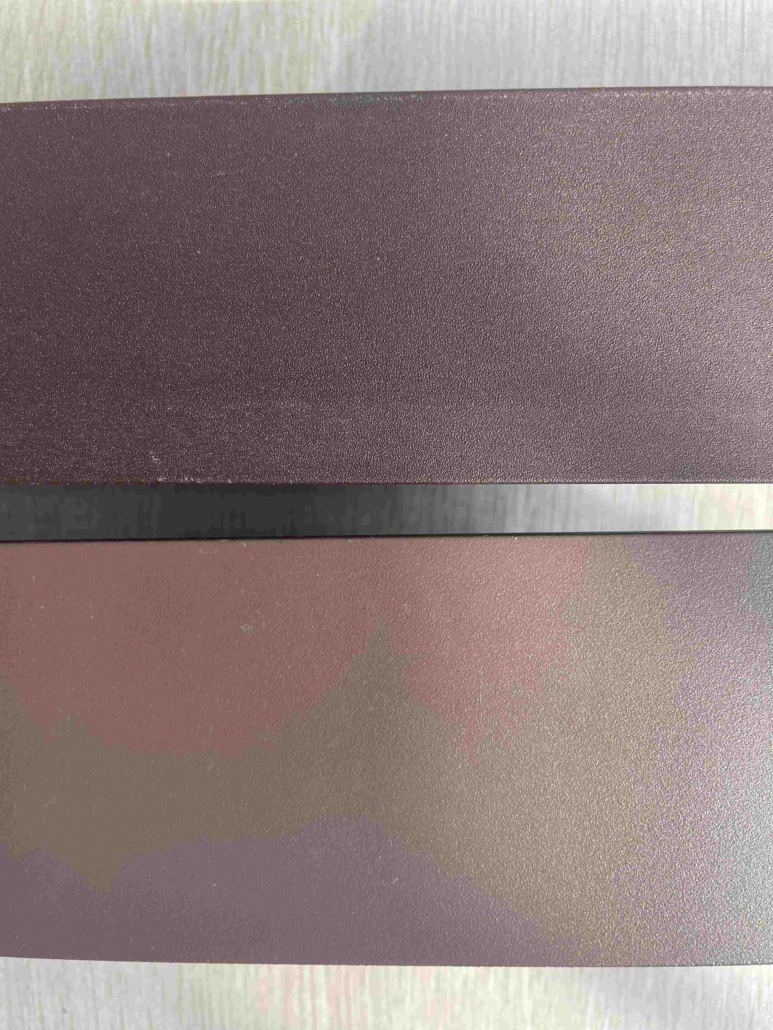

PE protective film for rough surface aluminum profiles

The adhesive performance of PE protective film will be superior to that of other material protective films because PE film is a soft material, regardless of whether it is a conventional profile or a special-shaped profile. As a result, our PE protection film for Rough Surface Aluminum Profiles is better suited for a rough surface that needs greater adherence, including Aluminum that has been sprayed or Aluminum that has been brushed.

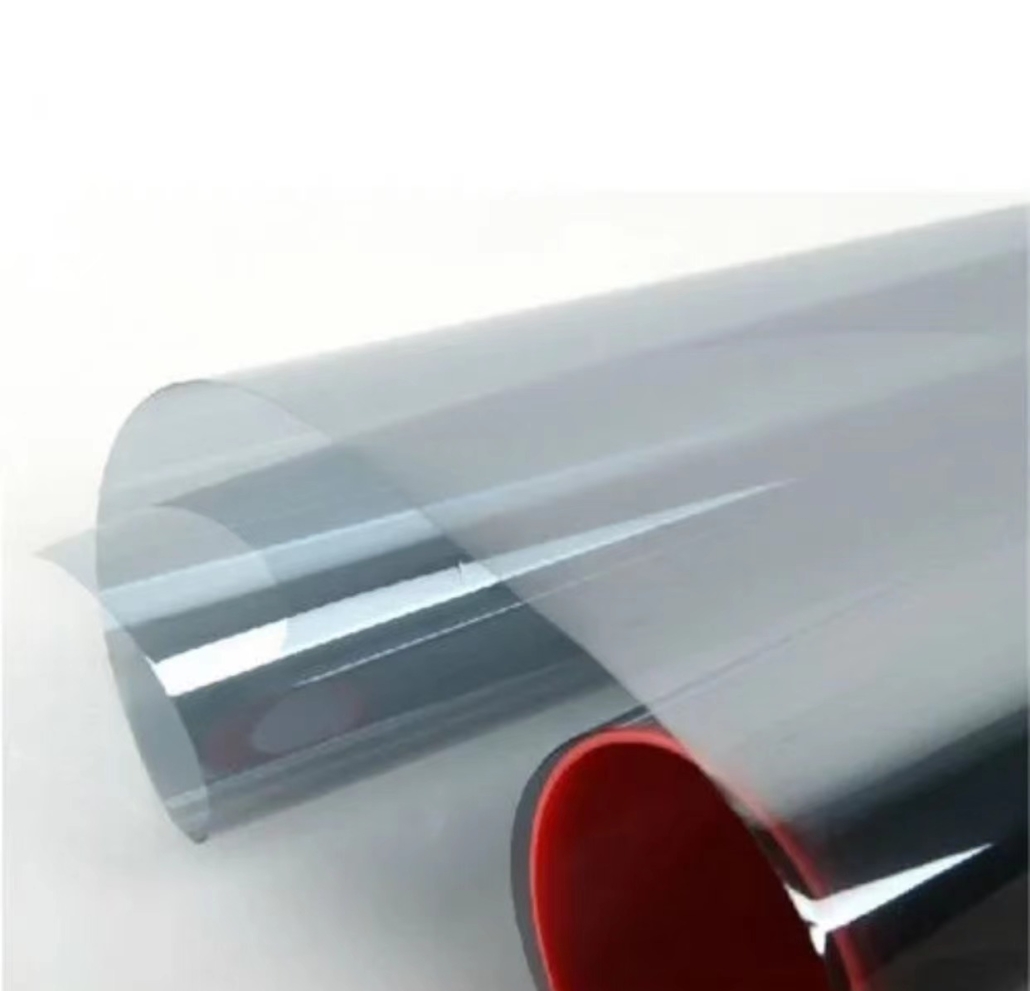

PE protective film for glass

It will aid in shielding your windows against spray paint, other sundries, and other activities, regardless of whether you use it for building, remodeling, repair, or other reasons! In addition, low-viscosity PE protective film can fulfill the viscosity criteria for glass since it has a smooth finish.

PE protective film for stainless steel

Any wear or damage will lower the value of stainless steel, and customer replacement will cost more money and take longer. To prevent stains, scuffs, or dust, our protective stainless tape may offer temporary protection for stainless plates during bending, stamping, installations, etc., to maintain the quality of stainless steel.

PE protective film for carpet

During construction, restoration, repair, or any other time, our carpet protection film will guard your carpet against dirt, dust, foot traffic, paint splashes, and other hazards. Because of its straightforward directions, this film is simple to apply and can be used by experts and novices. It is also simple to uninstall and leaves no trace behind.

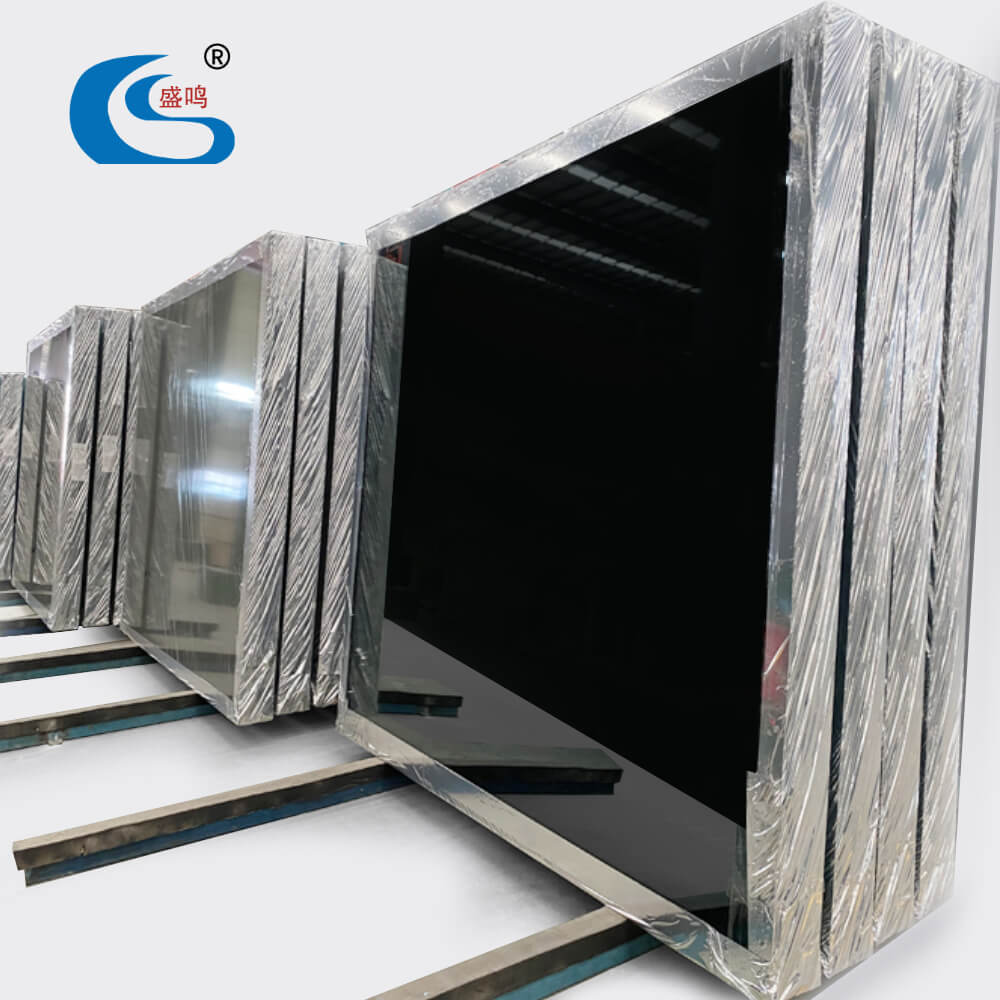

PE protective film for mirror

Its application is entirely distinct from other surface protection films and is made on the rear of the mirror. It is also known as mirror safety backing film. There is no need to remove it after installation because it is firmly attached to the rear of the silver-plated glass mirror. The mirror’s high viscosity and soft substance can aid in collecting the fragmented pieces when it is unintentionally damaged, minimizing the harm to the body.

Conclusion:

Our temporary surface protection film avoids recycled materials and uses only 100% of the original raw materials. In addition, our PE protective films come in different colors, and we can provide stunning logo printing to meet your needs. Contact us for more information regarding our PE films.