When customers choose protective film products, they often face such choices: PE film or PET film, how to choose? Before we answer this question, let’s look at what PE/PET film are:

Polyethylene film (also known as PE film), is a plastic film made from ethylene, a hydrocarbon that is mainly obtained from natural gas or petroleum.PE film is the most common plastic that can be found everywhere. It is used for a wide range of applications, such as packing, labels, plastic bags and etc.

Polyethylene terephthalate ( also called PET film), is the most common thermoplastic polymer resin of the polyester family and is used in fibers for clothing, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fiber for engineering resins. While used for packing, it could be aluminized by adding a thin film of metal aluminum onto it to reduce its permeability, to make it reflective and opaque.

Although PE or PET protective film could be used for packing, there are differences between them:

Material: PE film is a soft material, while PET film is a hard one.

Extensibility: PE has extensibility, its elongation varies from 150% to 300%. While PET has no extensibility.

Tensile strength and friction resistance: These two properties of PET film are better than PE film.

Weather resistance and anti-aging resistance: PE film can withstand max 70 ℃ temperature, while PET film can withstand up to 240 ℃.

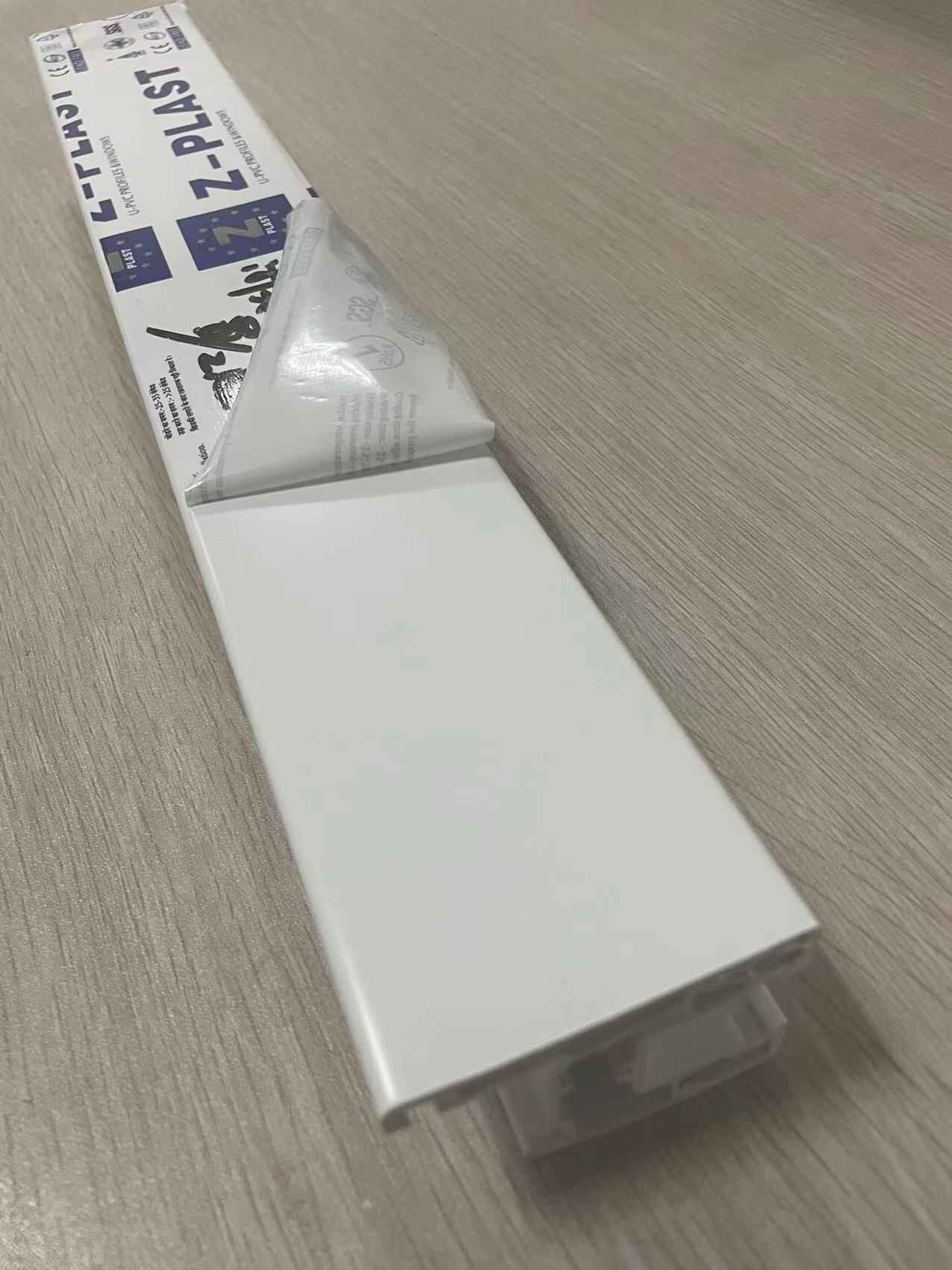

Our PE protective film is mostly used to supply temporary surface protection for aluminum window and door profiles, glass, and other building materials. Because of its softness, it could better fit protected surfaces than other materials. It is not only suitable for general material surfaces but is also recommended to use on rough surfaces like carpets, spray aluminum profiles, and other surfaces. However, it is not resistant to high temperatures and will break down under long-time sunlight. We usually suggest our customers tear them off asap, especially in summer. As the aluminum window and doors will absorb more heat, tearing them off asap could also help to avoid the risk of glue residue.

Our PET protective films have a double-layer composite structure. The first layer is an ordinary PET film, which can meet the needs of customized LOGO. The second layer uses the aluminized PET film mentioned above. It provides shading and sealing protection, so it could avoid the fading or aging of profiles to some extent. This film is recommended to use on PVC/UPVC profiles in high UV intensity / high-temperature areas. Through the feedback from the Xinjiang Branch of Zhongcai Profile, which is the leading manufacturer of PVC profiles in China, the outdoor anti-aging performance after 3 months is indeed better than other protective film products.

Each of the two materials has its own characteristics. Only when we totally understand customers’ demands, know what our customer’s most concerns are, and have full knowledge of the protected surfaces, can we provide customers with appropriate protective film solutions.