Development prospect

The pressure sensitive adhesive industry has been monopolized by international giants and multinational companies for a long time. Many domestic industries need high-end pressure sensitive adhesive products that rely on imports or joint ventures. Since the 1990s, domestic enterprises, scientific research institutes, and other enterprises and institutions gradually began to enter the independent research and development of products in this field. After years of technological accumulation, they have gradually obtained independent intellectual property rights in high-performance organic silicone, acrylic glue, anaerobic glue, epoxy resin glue and polyurethane glue, and other products, and their products are mainly aimed at replacing imports.

In the whole domestic pressure sensitive adhesive industry, there are more than 30 enterprises with independent research and development ability and a certain production scale [1], that own their own brands, and take pressure-sensitive adhesive products as their main business. Therefore, the domestic pressure sensitive adhesive has formed a comprehensive product structure and leading technology of multinational companies. Domestic enterprises focus on the segmentation of the field, and rapid growth, closely follows the competition pattern of foreign competitors, and the overall industry diversification is high.

Pressure sensitive adhesive is the high-end area of the adhesive industry, the requirements of enterprise research and development ability, product technology level, and sales channels are very high. After ten years of rapid growth, the growth of pressure sensitive adhesives has slowed down in recent years. The existing production capacity is excessive and the market competition is fierce, but the application field is constantly being developed, and the annual growth is still in double digits. The output of pressure sensitive adhesive has gradually increased in the past five years.

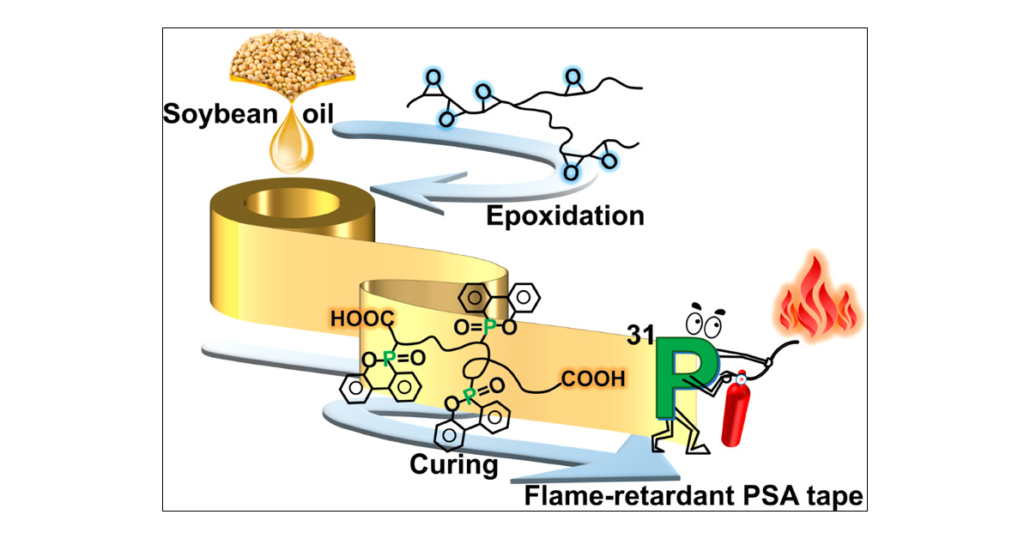

With the development and application of various new synthesis and curing methods, the performance of pressure sensitive adhesive has been greatly improved. At the same time, in order to meet the requirements of various applications, further development of its application field, but also developed many pressure sensitive adhesives with special functions and uses. The increasing demand for pressure sensitive adhesives in many industries further deepens the research on pressure sensitive adhesive, and the research and development of new pressure sensitive adhesives will be paid more and more attention to by people. In the future, pressure sensitive adhesive will be more environmentally friendly, more convenient, and in a higher performance direction.

What are the initial adhesion and peeling force of pressure sensitive adhesive?

Initial Tack force T (Tack), also called fast tack force, refers to the anti-separation ability shown when PSA products and adhesive are quickly separated immediately after contact with very light pressure.

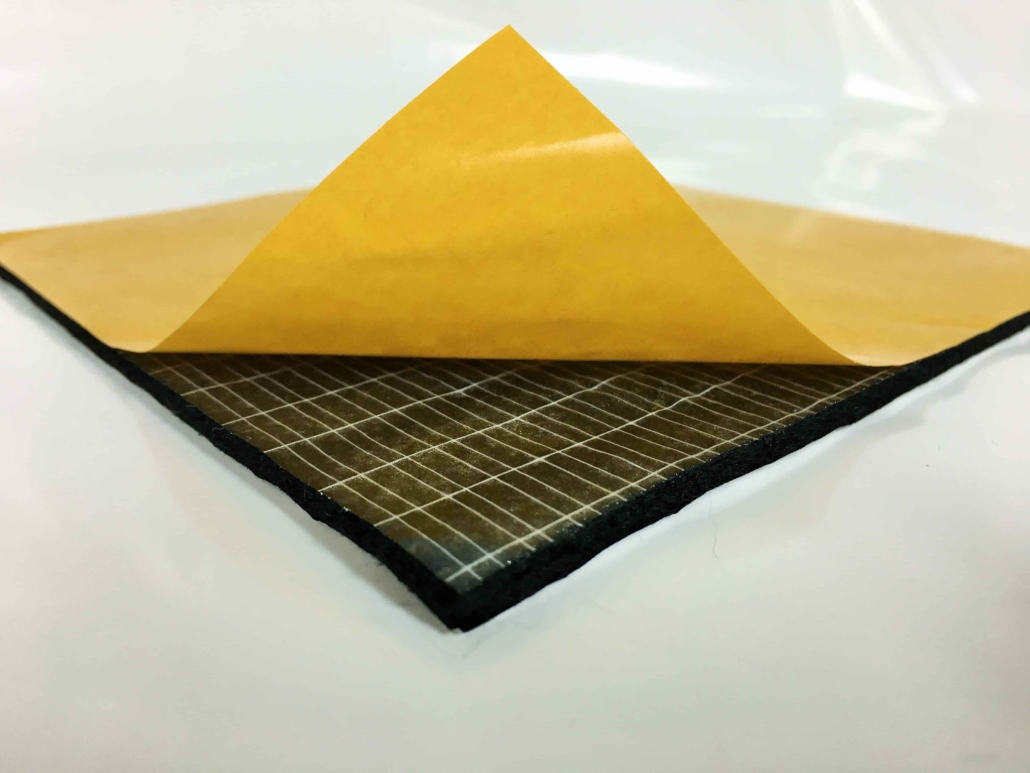

Adhesion A refers to the ability of adhesion to the PSA product and surface to resist interfacial separation by adhesion at appropriate pressure and time. C(cohesion) refers to the strength of the adhesive layer itself; Adhesive base force K (keying) refers to the adhesion between the adhesive and the substrate, or between the adhesive and the substrate and the substrate.

A good PSA must satisfy the balance of four adhesion properties, that is, T<A<C<K. This is because A must be greater than T, otherwise, PSA is not pressure-sensitive; C must be greater than A, otherwise, the adhesive layer will be destroyed when the tape is removed, resulting in adhesive pollution, sticky surface, wire drawing, and other defects; C must be less than K, otherwise the adhesive layer will be separated from the substrate.

The peeling force of the pressure-sensitive adhesive (the peeling force between the adhesive tape and the adhesive surface) < the cohesion of the adhesive (the force between the molecules of the pressure-sensitive adhesive) < the adhesive base force (the adhesion between the adhesive and the substrate). Such a pressure sensitive adhesive in the process of use will not have the phenomenon of degumming.