Acrylate adhesives are commonly used in daily life. Acrylate hot melt adhesives have high bond strength and shear strength, and their oxidation resistance and weather resistance are good. In this paper, a large number of experiments and research work have been carried out based on the current development status of acrylate hot melt adhesives and the problems of adhesive removal in the bonding of waxed paper boxes and waste paper recycling.

The main research results include (1) Methyl methacrylate (MMA), laurel methacrylate (LMA), vinyl acetate (VAc), and acrylic acid as copolymers and potassium persulfate as initiation The re-dispersible acrylate hot melt adhesive was prepared by semicontinuous emulsion polymerization.

When the ratio of Op-10 to Span-80 of the paraffin composite emulsifier is 0.55/0.45, the paraffin emulsion can be prepared. When the contents of LMA, n-dodecyl mercaptan (NDM), and N-(methoxymethyl) acrylamide are 9%, 0.8%, and 0.3%, respectively, the reaction conversion rate can reach 95.59%, and the polymer has excellent thermal performance and bond strength.

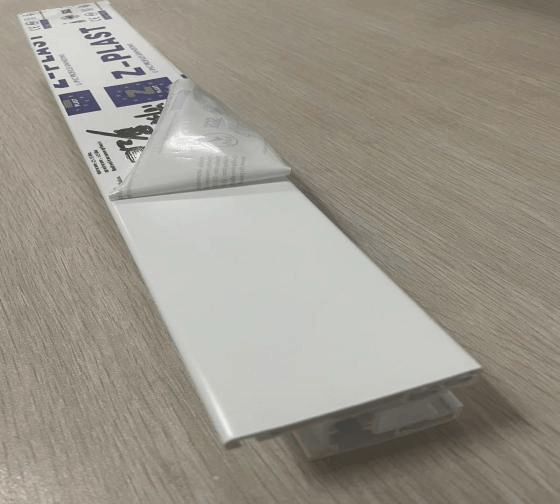

Adding dioctyl phthalate (DOP) and rosin continues to improve the melt fluidity and adhesion of hot melt adhesive, DOP and rosin content is 7.5% and 6% of the mass of the matrix polymer, respectively, redispersing acrylate hot melt adhesive has excellent thermal stability, low melt viscosity, high bond strength, good redispersing effect, used in paper products bonding and carton sealing, can be reduced It is difficult to deal with adhesive when recycling fewer paper products, so as to realize efficient recycling of paper products.

(2) Using VAc, MMA, acrylic acid, and butyl acrylate as the copolymer and potassium persulfate as the initiator, the low-temperature hot melt adhesive which can be used for the sealing of waxed paper box was prepared by semi-continuous emulsion polymerization. When the paraffin emulsion content is 10%, the composite emulsion is more stable and the polymer melting fluidity is suitable.

When the content of MMA is 5.2%, the reaction conversion rate is higher, the peel strength of the polymer can reach 55N/25mm, and the shear strength is higher. When DOP is added to improve the bonding strength and melting viscosity of the hot melt adhesive, the low-temperature hot melt adhesive prepared by DOP content is 10% of the mass of the matrix polymer has good comprehensive performance and can be used in the sealing bonding of the impregnated wax paper box. Low-temperature hot melt adhesive has excellent bonding strength, avoid the wax paper box nail caused damage to the goods in the box.

(3) The process flow chart of two kinds of hot melt adhesives is drawn, and the material balance and cost accounting are carried out respectively. According to the comparison with the hot melt adhesives sold on the market, the two kinds of low-temperature hot melt adhesives prepared in this experiment are reasonable in price, excellent in comprehensive performance, and competitive in the market.