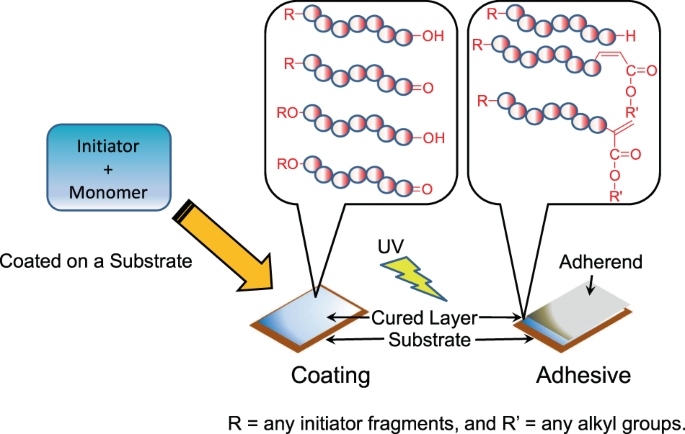

(1), 65 g beta-acryloyl oxygen radicals propionic acid, 90 g butanone, 2. 4 g disulfide are two butyl xanthate ester, 0. 3 g azodiisobutyronitrile added to the reactor, mix again after vacuum at room temperature, ventilation with nitrogen gas, reaction 72 h under 65 ℃, three ethanol amine neutralization, and pH value of 7, Adding 35g hexafluorobutyl acrylate, 0.3g diisobutyronitrile, through nitrogen, reaction at 65℃ for 12h, and then vacuum at 60℃ to remove butyl ketone, fluorophile amphiphilic block oligomers were obtained.

(2) Weigh 1.5g fluoro-containing amphiphilic block oligomers prepared in step (1), add them into 70g deionized water, and stir at constant temperature to obtain an emulsifier aqueous solution. Then to slow in 160 g of methyl methacrylate, 40 g different borneol acrylate, butyl acrylate, 60 g 1 g trifluoro ethyl acrylate, 1 g trifluoro ethyl methacrylate, 1 g five fluorine propyl acrylate, 15 designed.the gn-hydroxyethyl acrylamide, 0. 6 g is amyl alcohol, 3 g ammonium persulfate, stirring 40 min, The stirring speed was 400r/min, and the monomer preemulsion was obtained.

(3) Add 20g deionized water to the reactor and heat it to 80℃, add 3.53g monomer preemulsion prepared in step (2) and react for 20min, then add the remaining monomer preemulsion to the reactor for 5h to react, and keep it warm at 80℃ for 1h after the drip, and then cool it to 65℃. Said take 1 g hydroxy acetic acid and sulfonic acid disodium dissolved in deionized water, 10 g within 30 min and added to the reaction kettle, 30 min insulation, cooling below 45 ℃ in BS-adjust pH value to 7, 168 then add 0. 6 g silicone wetting agent, 1 g of organic silicon class defoaming agent mixing 30 min, filter the material, Low surface hydrophobic acrylic pressure sensitive adhesive is obtained.