A pressure-sensitive adhesive (PSA) is widely used in different applications to protect surfaces from various problems. The applications of PSAs may vary in every industry which helps to maintain the quality of products. PSAs work well on several substrates with optimal performance. They involve different types, and industries should evaluate them properly to make informed decisions. Moreover, industries can select the right products that satisfy their requirements. While selecting PSAs, it is wise to consider certain things that allow users to accomplish their goals.

What are some variables to keep in mind when selecting PSAs?

PSAs are suitable for bonding purposes with a variety of materials by addressing their exact needs. However, industries should choose the best products that cater to the requirements of specific applications.

Here are some variables to consider when selecting PSAs.

- Understanding the PSA types

Industries should gather more details about PSA types before buying them. Furthermore, they can know how well adhesives adhere to various materials, which helps determine the best combination. For instance, a general-purpose rubber adhesive works very well with polyester urethane. An industry should determine the purpose while selecting PSAs.

- End-use requirements

PSAs may face a variety of situations during their lifecycle, and each situation may face various challenges. Therefore, industries should consider some important things while choosing PSAs for an application. They include humidity resistance, UV resistance, shear strength, chemical resistance, etc.

- Surface energy

Surface energy is another important factor to keep in mind when selecting PSAs. This is because picking the wrong surface may not produce an effective bond. Industries should make sure that the surface works well when it comes to adhesion.

- Construction

When selecting PSAs, industries should evaluate the construction process with more attention to ensure high efficiency and optimal performance.

What are the properties of pressure-sensitive adhesives?

- Good resistance

Pressure-sensitive adhesives have good resistance to varying temperatures, chemicals, UV rays, oxidation, etc.

- Adhesion

Most PSAs will have good adhesive properties that provide methods to protect the surfaces from unwanted problems.

- Cohesion

PSAs can stick together under stresses like high heat and shear. Apart from this, they are highly durable and help enhance the lifespan of surfaces.

What are the factors that can influence the performance of PSAs?

- Surface condition

An application’s surface may impact the performance of PSAs, and industries should consider the same with more attention. It is important to evaluate the surface energy of the substrate and understand the application’s surface condition before applying adhesives.

- Environmental conditions

Environmental conditions such as humidity, UV light, and temperature extremes can affect the performance of PSAs. Therefore, industries should ensure that PSAs withstand the necessary environmental conditions.

- Application condition

End users should consider the application condition before buying pressure-sensitive adhesives from the market to determine the adhesive’s success. An adhesive should withstand application conditions to form a successful bond.

- Bonding process

Many PSAs require minimal time to achieve bond strength due to instant adhesion. On the other hand, industries should evaluate the same while using PSAs for quick assembly applications.

- Reusability and removability

Some PSAs exhibit reversible adhesion, enabling the surfaces to meet exact requirements for repositioning and reusing. It will benefit the surfaces when they need temporary bonding or adjustments.

- Molecular structure and composition

Both molecular structure and composition will influence the performance of PSAs that need a deep study.

Wuxi Changsheng offers the best PSAs on the market.

Wuxi Changsheng is a reputed manufacturer of pressure-sensitive adhesives that offers a wide range of products for different applications. Our primary objective is to satisfy the needs of industries and other customers when they are looking for the best products. We provide high-quality adhesives for different industries to ensure better performance.

All our pressure-sensitive adhesives undergo various experiments and processes to make sure that they cater to the needs of end users. Our company’s product development team will study the latest market trends and requirements, including applications, before making PSAs.

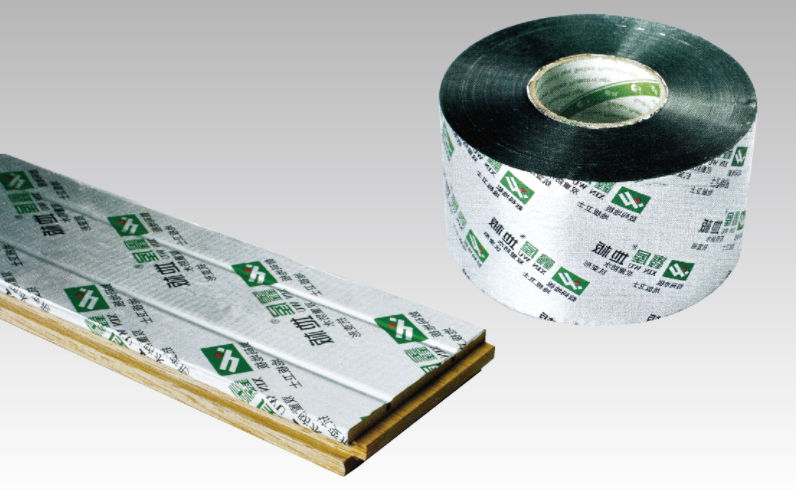

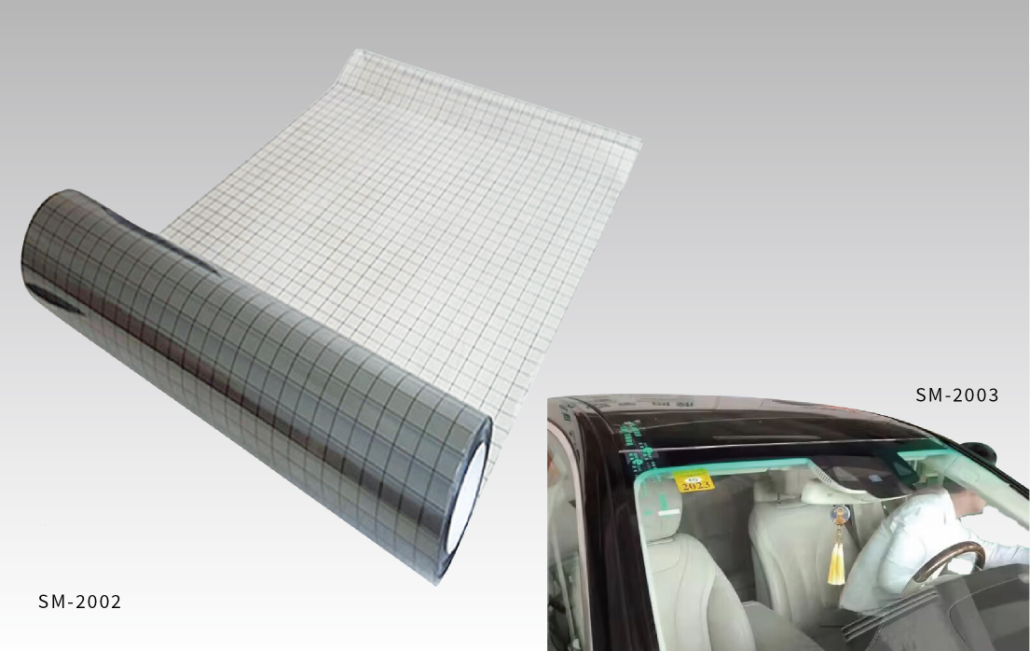

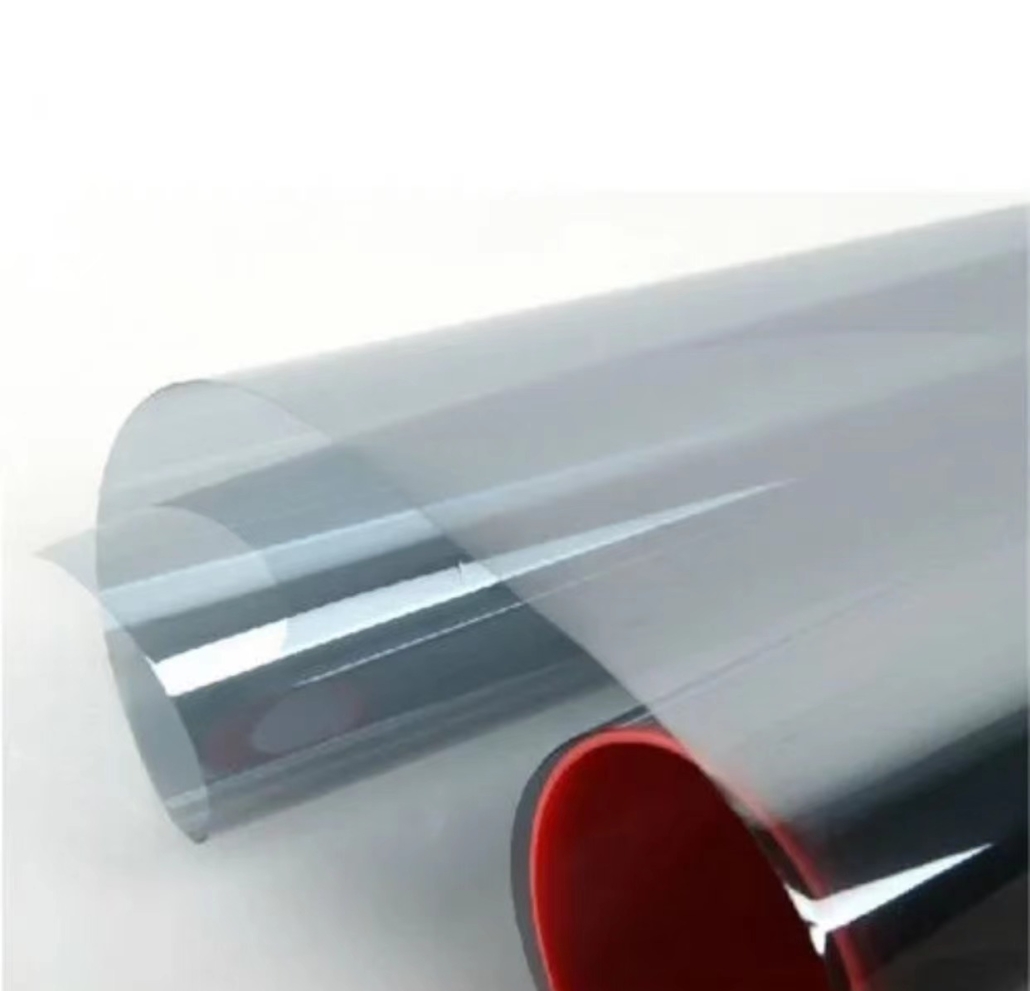

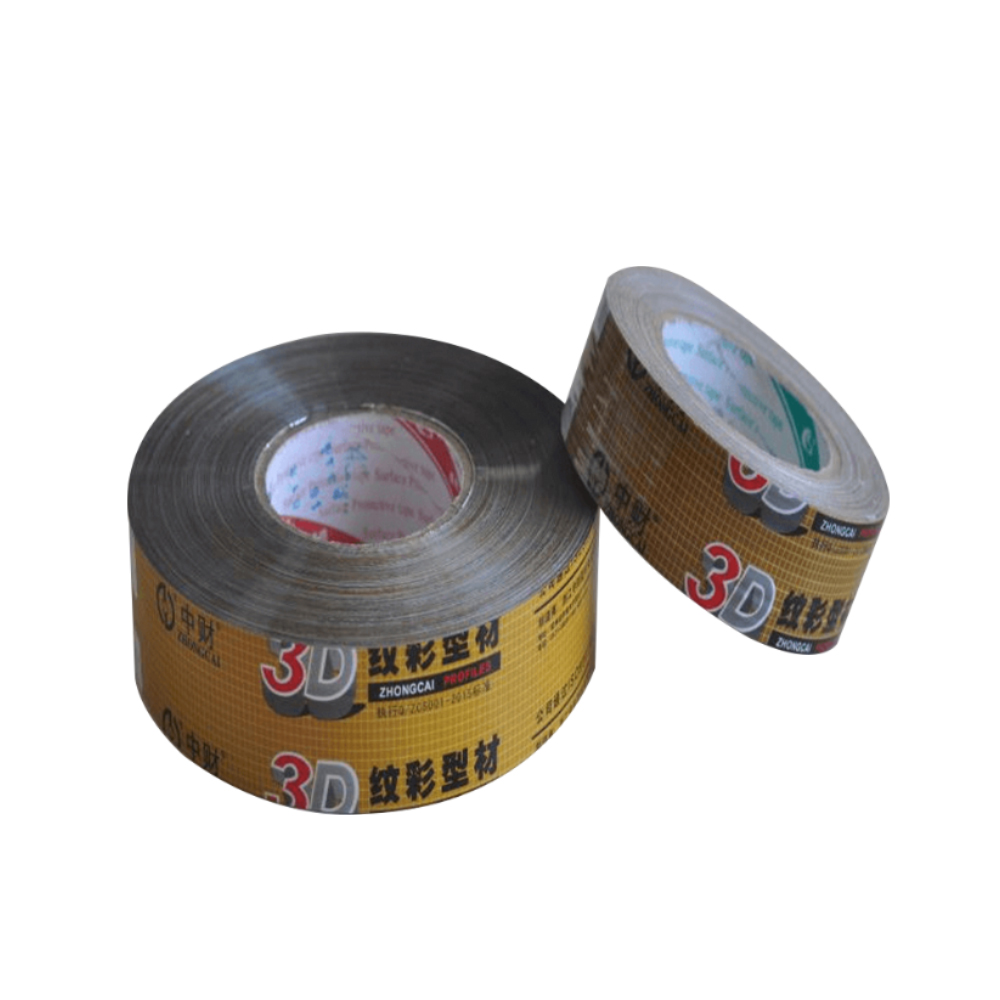

Our PSAs are suitable for packaging, manufacturing, and other industries to ensure high-level protection for the surfaces. They are durable, resistant, eco-friendly, and affordable, enabling end users to gain more advantages.

Why choose us for buying PSAs?

- A variety of products

Our company offers a variety of pressure-sensitive adhesive products that come with better performance.

- Our PSAs are available in various sizes

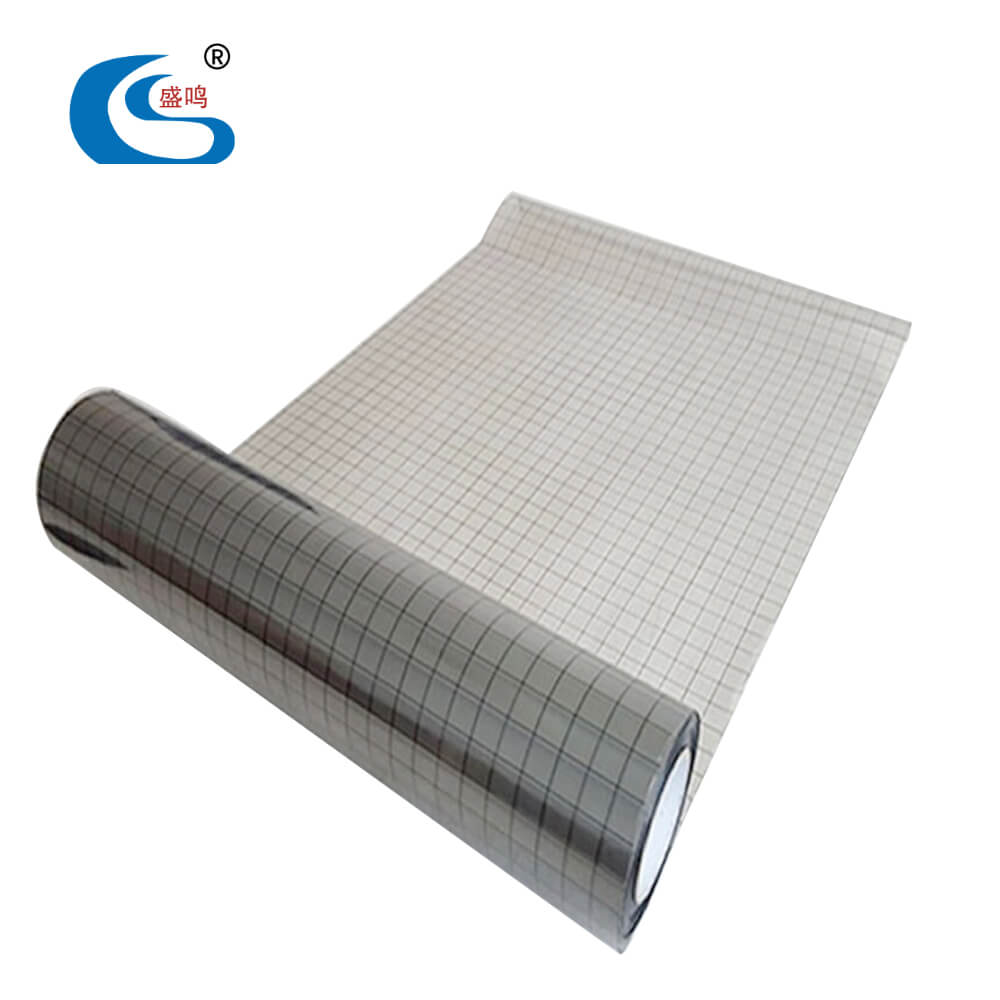

We provide PSAs in various sizes that suit the requirements of industries when they want to protect the surfaces of products from potential hazards.

- Satisfaction Guarantee

Satisfaction guarantee is the primary goal of our company while delivering pressure-sensitive adhesives to customers.

- Easy to use and remove

All our PSA products are easy to use on surfaces, and industries can remove them without any difficulties.

Industries and suppliers can contact us through email to learn more about our products in detail.