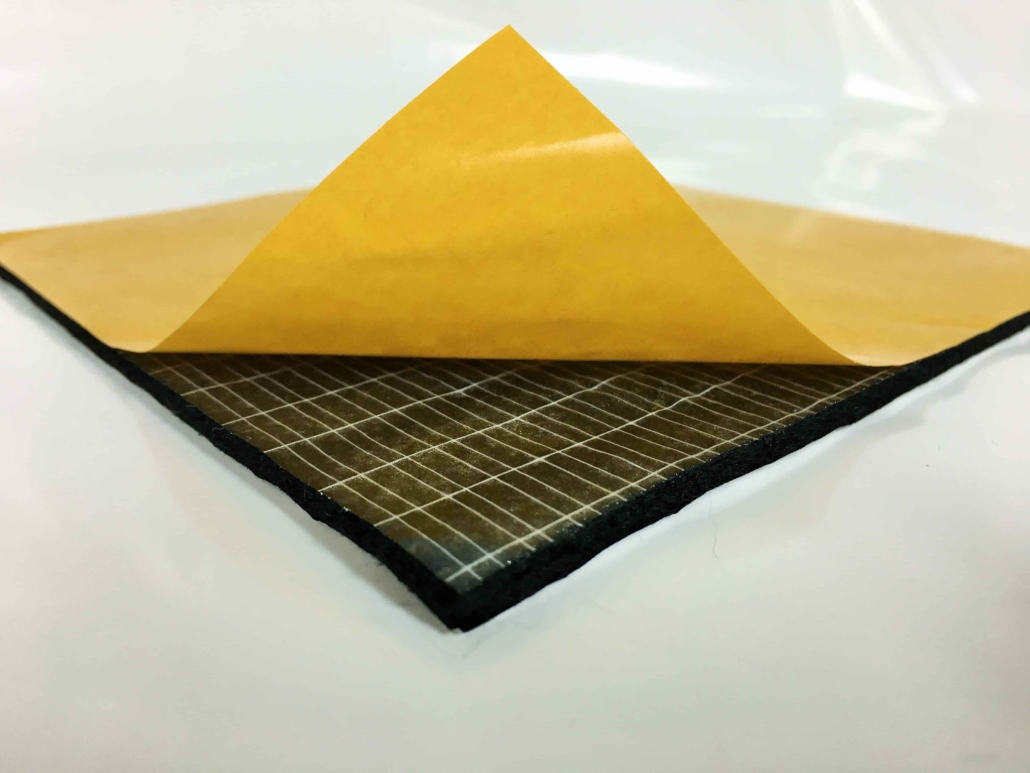

The full name of pressure sensitive adhesive is pressure sensitive adhesive, also known as self-adhesive, referred to as pressure sensitive adhesive. Pressure-sensitive adhesive products include pressure-sensitive adhesive tape and pressure sensitive adhesive label paper, and pressure-sensitive film in three categories. Their full name is a pressure-sensitive adhesive tape, pressure-sensitive adhesive label paper, pressure-sensitive adhesive sheet, commonly known as adhesive tape, self-adhesive label paper, and pressure-sensitive film.

This component is adjusted to achieve better performance of the product. In order to ensure the good adhesion and peeling strength of pressure-sensitive adhesive in the existing technology, a large number of chemical reagents are often added, which greatly increases the production cost and also produces a large number of toxic chemical raw materials.

As a professional acrylic pressure-sensitive adhesive supplier, Changsheng is committed to solving the problems encountered by customers in the use of glue due to different production equipment and processes.

Compared with traditional solvent-based pressure-sensitive adhesive, our emulsion pressure-sensitive adhesive has the advantages of environmental protection, safety, and easy operation. Using deionized water instead of traditional solvent reduces pollution to the environment and is an ideal environmental protection product.

By adjusting the proportion of the curing agents, pressure-sensitive adhesives with different adhesive forces can be obtained to meet the needs of different applications. Suitable for a variety of materials, transparent after drying.

Our acrylic pressure-sensitive adhesive is widely used in:

1. Fit of different film materials

Hot item: Glue FR-201

Advantages: Our laminating adhesive has strong peeling strength, suitable for laminating BOPP, CPP, PET, PE or other lightweight packaging film materials.

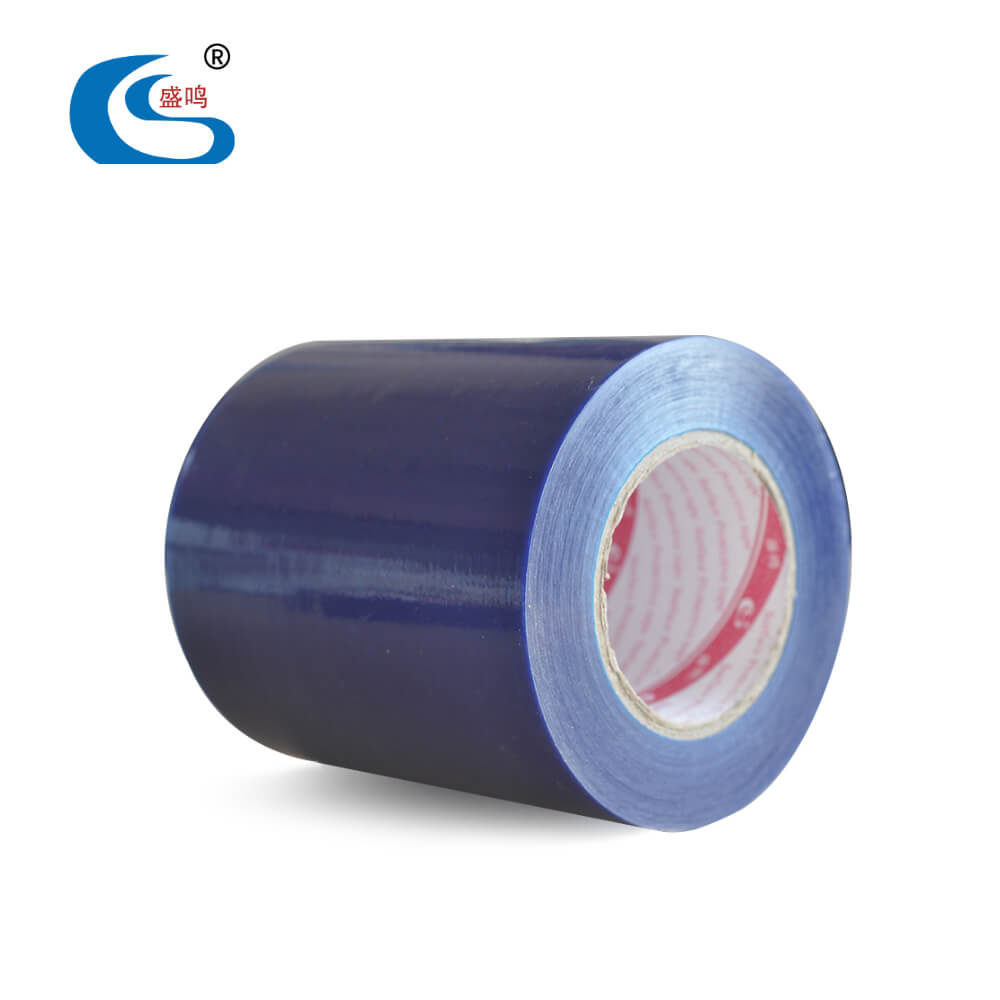

2. Protective film for household appliances

Hot stuff: Glue FR-07; Glue FR-102-2

Advantages: The series of adhesive peeling force increase small, do not leave residue, good anti-scalding performance.

The FR-07 is suitable for smooth surfaces of stainless steel, and the FR-102-2 is suitable for slightly rough surfaces.

3, outdoor protective film

Hot stuff: Glue FR-04; Glue FR-W78-1; Glue FR-091-6

Advantages: This series of glue has the advantages of temperature resistance (including high and low temperature), moisture-proof, and waterproof performance. Their adhesive force is different and can meet different bonding requirements.

Glue FR-091-6 is especially suitable for carpets, fluorocarbon spray aluminum profiles, and other rough surface.

4. Off-line Low-E glass protective film

Hot item: FR-08-J7

Strength: It has the characteristics of strong stripping strength and moderate unwinding performance.

Wuxi Changsheng Adhesive Products Co., Ltd. is also committed to emulsion pressure-sensitive adhesive research and development, production, and sales of the company. We can effectively solve the problems that customers encounter in the use of glue because of different production equipment and technology.

We specialize in the production of the protective film and pressure-sensitive adhesive for many years, with our own R & D team. In the future, through continuous research and development and summing up experience, our glue can be applied to more product application fields.