The traditional mobile phone battery fixing method is to directly fix the mobile phone battery with a double-sided adhesive on the base. When the mobile phone battery needs to be repaired and replaced, on the one hand, it is inconvenient to disassemble, on the other hand, disassembly will cause bending or damage to the battery, and even outflow of battery electrolyte, damage the mobile phone and human health.

Chinese patent CN 207418650 U discloses a kind of easy to tear tape wrapped battery, this kind of easy to tear tape can be wrapped into the mobile phone, when the need to repair or replace the mobile phone battery, only need to pull the removable film of easy-to-tear tape, the battery can be removed from the easy to tear tape, so as to realize the battery without damage disassembly. However, this method requires a double-sided adhesive to fix the easy-to-tear tape wrapped in the battery compartment of the mobile phone, which takes time to operate and increases the process and cost of battery packaging.

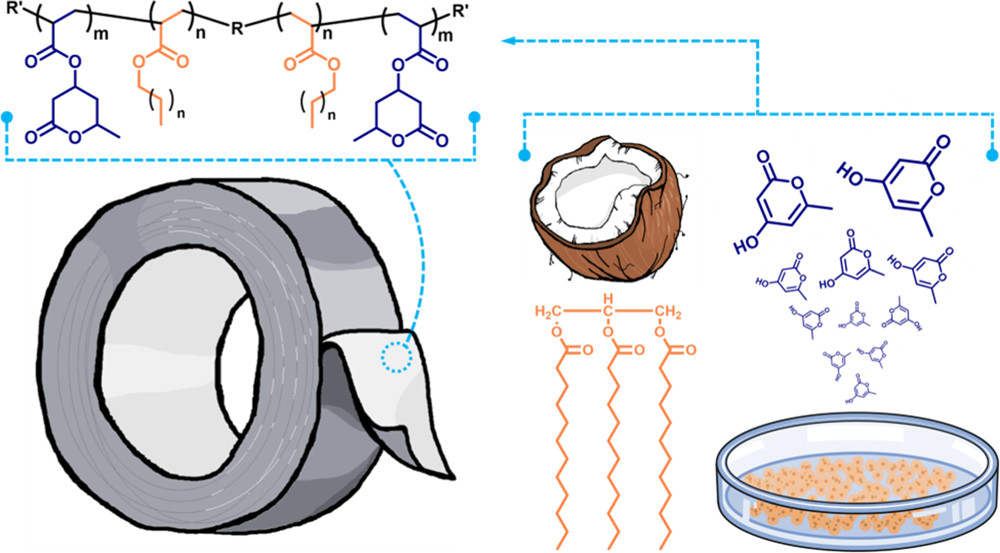

On this basis, it is necessary to provide a double-sided pressure-sensitive tape for fixing the mobile phone battery, which can realize the rapid and non-damaging disassembly of the battery, simplify the assembling process of the mobile phone battery, and at the same time realize the tape thinning and provide space for increasing the capacity of mobile phone battery. In order to solve the above technical problems, the invention adopts the following technical scheme: a double-sided pressure-sensitive tape comprises a first-release film, a first pressure-sensitive adhesive layer, a base layer, a second pressure-sensitive adhesive layer, and a second-release film arranged successively from bottom to top; The 180 degree peeling force of the first pressure-sensitive adhesive layer is 20N/24mm ~ 35N/24mm; The 180 degree peeling force of the second pressure-sensitive adhesive layer is 10N/24mm ~ 20N/24mm.

The invention also provides a preparation method for the double-sided pressure sensitive tape, including the following steps: Step S1: Prepare a first polyacrylate pressure sensitive adhesive and a second polyacrylate pressure sensitive adhesive; Step S2: the first polyacrylate pressure sensitive adhesive is coated on one side of the base, and then the base is put into the drying temperature of 75℃ ~ 85℃, 85℃ ~ 95℃, 95℃ ~ 105℃, 95℃ ~ 105℃, 85℃ ~ 95℃ and 75℃ ~ 85℃ in the oven drying, each drying time is 10s ~ 14s; The first polyacrylate pressure sensitive adhesive after drying to form a first pressure sensitive adhesive layer; The first pressure sensitive adhesive layer is coated with a first release film; Step S3: the second polyacrylate pressure sensitive adhesive is coated on the other side of the base, and then the base is put into the drying temperature of 75℃ ~ 85℃, 85℃ ~ 95℃, 95℃ ~ 105℃, 95℃ ~ 105℃, 85℃ ~ 95℃ and 75℃ ~ 85℃ in the oven drying, each drying time is 10s ~ 14s; The second polyacrylate pressure sensitive adhesive after drying to form a second pressure sensitive adhesive layer; The double-sided pressure sensitive tape is prepared by covering the second pressure sensitive adhesive layer with a second release film. After six dryings, the first pressure-sensitive adhesive layer and the second pressure-sensitive adhesive layer have a high drying degree and reduce the appearance of bubbles in the adhesive layer.