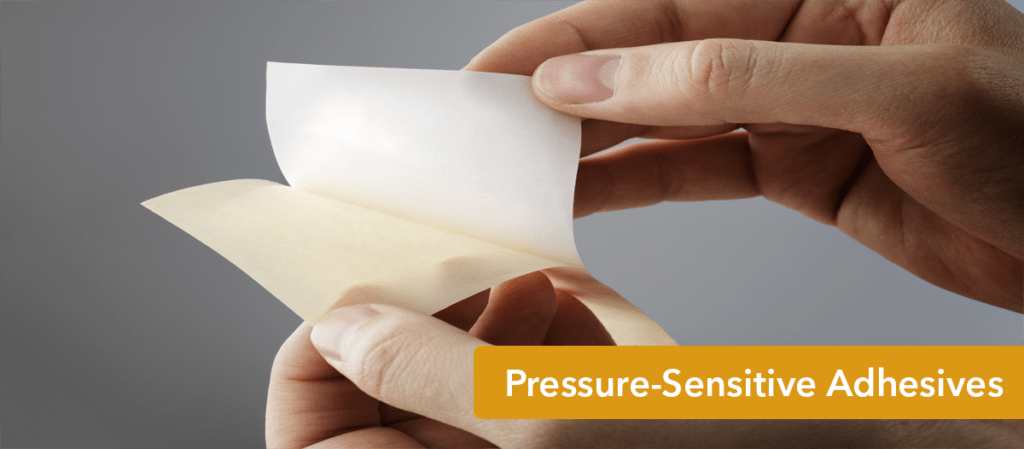

Pressure sensitive adhesive, as the name implies, is a pressure sensitive adhesive, it is a kind of adhesive without the aid of a solvent, heat, or other means, only needs to apply mild pressure, and can be firmly bonded with the adhesive. Pressure-sensitive adhesive is characterized by easy adhesion, uncovering is not difficult, stripping is not damaged, and the adhesive layer will not dry up over a long time, so the pressure-sensitive adhesive is also known as self-adhesive.

It is because of the above characteristics of pressure sensitive adhesive, pressure sensitive adhesive products have a very wide range of uses. Acrylate pressure-sensitive adhesive is the most widely used pressure-sensitive adhesive at present, it is the copolymer of an acrylate monomer and another ethylene monomer.

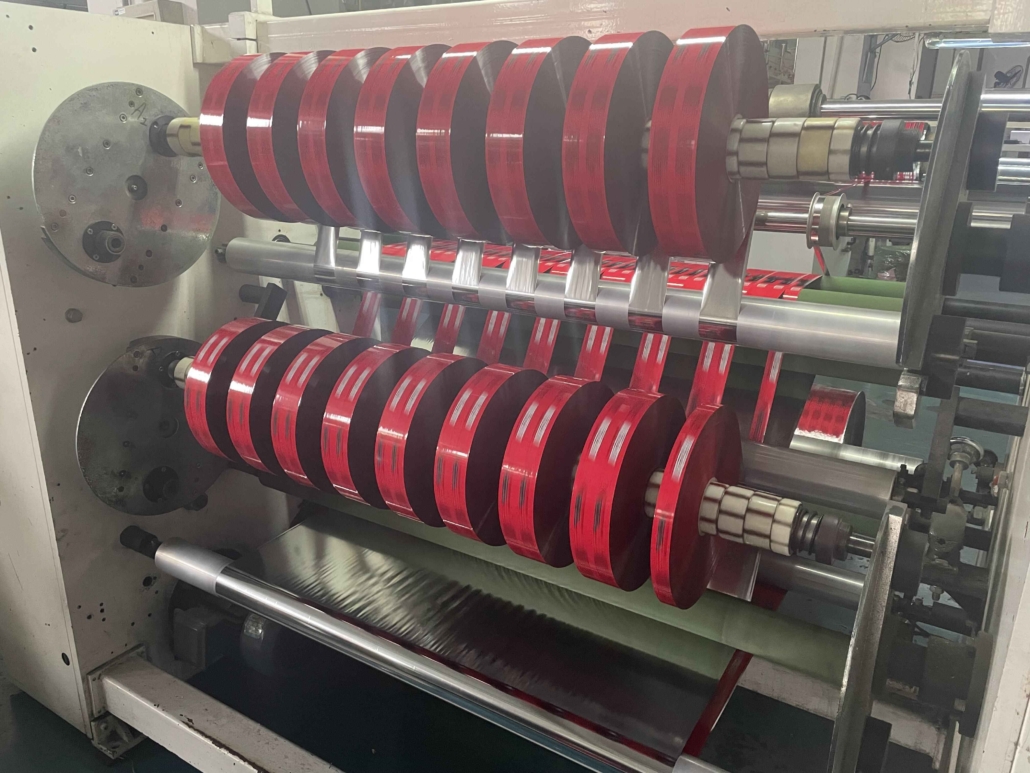

Acrylate pressure-sensitive adhesive mainly includes solvent pressure-sensitive adhesive and emulsion pressure-sensitive adhesive. Among them, solvent-based pressure-sensitive adhesive has been widely used in many fields, and their dosage accounts for more than 65% of the whole pressure-sensitive adhesive.

Especially in the past two decades, this kind of pressure-sensitive adhesive has developed very rapidly and gradually replaced the position of natural rubber pressure-sensitive adhesive. Widely used in packaging, coating, transportation, electronic communications, electrical appliances, building materials, machinery, aerospace, light industry, medical, family life, and many other fields.

However, the current use of pressure-sensitive adhesive still has the following problems: 1. The peeling force and adhesion of pressure-sensitive adhesive are not high enough, and the bond firmness is not enough;2. The pressure-sensitive adhesive has poor plasticizer resistance and temperature resistance; 3, the synthesis of pressure-sensitive adhesive using benzene, toluene, and other solvents, high toxicity, and no environmental protection, limits its use.

Smprotectivefilm is also committed to the emulsion pressure-sensitive adhesive research and development, production, and sales of the company. We can effectively solve the problems that customers encounter in the use of glue because of different production equipment and technology.

We specialize in the production of the protective film and pressure-sensitive adhesive for many years, with our own R & D team. In the future, through continuous research and development and summing up experience, our glue can be applied to more product application fields.

Our acrylic pressure-sensitive adhesive is widely used in:

- Fit of different film materials

Hot item: Glue FR-201

Advantages: Our laminating adhesive has strong peeling strength, suitable for laminating BOPP, CPP, PET, PE or other lightweight packaging film materials.

- Protective film for household appliances

Hot stuff: Glue FR-07; Glue FR-102-2

Advantages: The series of adhesive peeling force increase small, does not leave residue, good anti-scalding performance.

The FR-07 is suitable for smooth surfaces of stainless steel, and the FR-102-2 is suitable for slightly rough surfaces.

- Outdoor protective film

Hot stuff: Glue FR-04; Glue FR-W78-1; Glue FR-091-6

Advantages: This series of glue has the advantages of temperature resistance (including high and low temperature), moisture-proof, and waterproof performance. Their adhesive force is different and can meet different bonding requirements.

Glue FR-091-6 is especially suitable for carpets, fluorocarbon spray aluminum profiles, and another rough surface.

- Off-line Low-E glass protective film

Hot item: FR-08-J7

Strength: It has the characteristics of strong stripping strength and moderate unwinding performance.