As a kind of adhesive material, tape has its special application, such as fixed bonding of materials, surface protection and so on. Nowadays, with the upgrading of the electronic industry is getting faster and faster, the requirements for electronic adhesive tape are getting higher and higher.

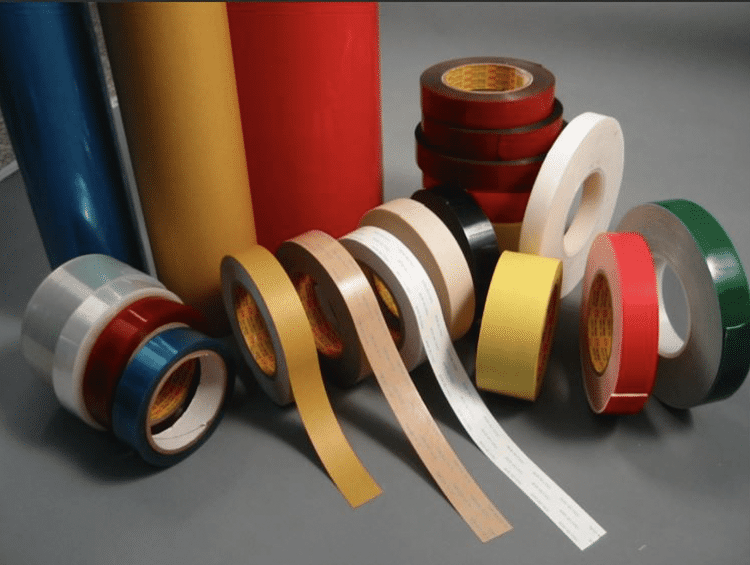

More electronic applications have put forward the tape not only needs high bonding strength, but also requires strong bonding of different surface energy materials. There are further requirements such as living reagent resistance, such as laundry detergent, sweat, alcohol, food grease and so on. These properties are precisely what most ordinary tape cannot achieve. Some high bonding strength tape has appeared on the market, such as 3M VHB tape, the foam tape is mainly composed of intermediate foam structural layer and two sides coated with high, medium and low surface energy type of high strength acrylic pressure sensitive adhesive, acrylic pressure sensitive adhesive provides high bonding strength, the intermediate foam layer provides stress dispersion, can bond different surface energy materials, and bond more firmly.

Also such as AB double-sided adhesive on the market, by using different surface energy adhesives on both sides of the PET film substrate coating, can bond low and medium surface energy plastic and high surface energy metal plate. As mentioned above, there are high bonding strength tapes on the market that can bond different surface energy materials, such as VHB foam tape produced by 3M.

This tape has high bonding strength and good stress dispersion, but it is not able to withstand living reagents. Another example is the high bonding strength AB tape, which can also be well bonded to different surface energy materials, but the same resistance to living reagents is poor, and the stress of the tape is easy to concentrate, resulting in a decline in bonding durability. Therefore, it is necessary to seek a special pressure sensitive adhesive composition and adhesive tape with high bond strength, good resistance to living reagents, and suitable for ultra-thin bonding occasions.

As a professional acrylic pressure sensitive adhesive supplier, Smprotectivefilm is committed to solving the glue problems encountered by customers due to different production equipment and processes.

Compared with traditional solvent-based pressure sensitive adhesive, our emulsion pressure sensitive adhesive has the advantages of environmental protection, safety and easy operation. Using deionized water instead of traditional solvent reduces the pollution to the environment and is an ideal environmental protection product.

By adjusting the proportion of curing agent, pressure sensitive adhesive with different adhesive force can be obtained to meet the needs of different applications. Suitable for a variety of materials, transparent after drying.