The Dyne value of membrane material refers to an index of the adsorption effect of the surface of the material, which can reflect a key parameter of the adhesion of the membrane material. Generally, the corresponding value of the Dyne pen can be used for detection. Dyne pens come in a variety of Dyne values, ranging from the high 30s to the high 70s. Dyne value comes from Dyne, Dyne is a unit of force, usually, we say the surface tension, Dyne value is a popular name, accurately said should be the surface tension coefficient. Defined as the force pulling on each other per unit length between two adjacent parts of a liquid surface. The unit of surface tension in the SI system is Newton/meter (N/m), but dyn/ centimeter (dyn/cm) is still commonly used, 1dyn/cm = 1mN/m.

The Dyne value standard, which refers to the membrane by Dyne pen test out of the surface tension value, is also the decisive standard for membrane surface treatment, generally speaking, Dyne value is higher, the adhesion of the paste will be better, Dyne value is higher, the more surface energy, so the surface is easier to accept ink. If the surface Dyne value is too low, the ink will not dry and will flake.

Contact angle: Contact Angle refers to the tangent line of the gas-liquid interface made at the intersection of gas, liquid, and solid three phases. The Angle θ between the tangent line on the liquid side and the boundary between solid and liquid is a measure of the degree of wetting.

If θ<90°, the solid surface is hydrophilic, with high surface energy, and a high Dyne value, that is, the liquid is easier to wet solid, the smaller the Angle, the better wettability;

If θ>90°, the solid surface is hydrophobic, with low surface energy and a low Dyne value, that is, the liquid does not easily wet the solid and easily moves on the surface.

Surface free energy, Dyne value, and contact Angle are all methods for evaluating the wettability of solid surfaces. Relatively speaking, the contact Angle measuring instrument is more accurate, followed by surface free energy, and the Dyne pen is quick and rough.

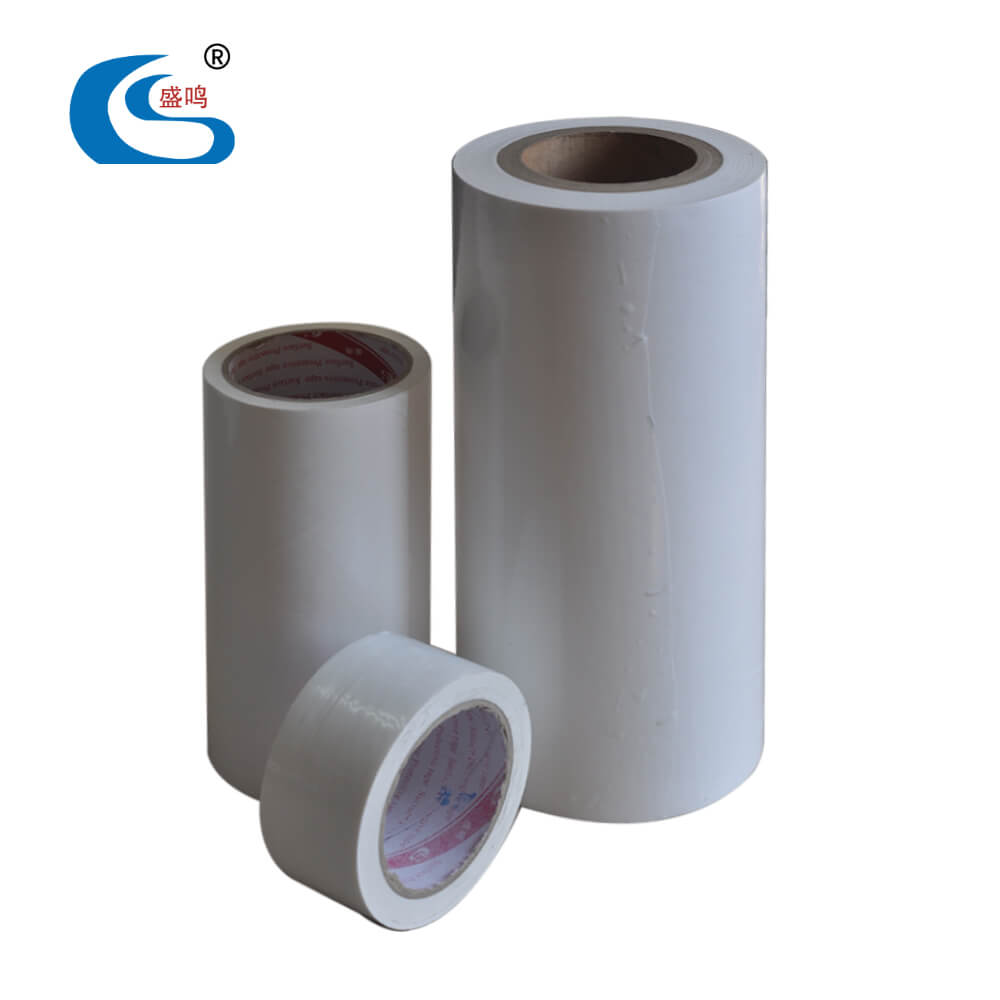

To test the Dyne value of the protective film, we need to use a special tool, called the Dyne pen, Dyne pen is a little like our common water-based pen, we only need to select the corresponding Dyne value of the pen on the surface of the tested protective film to draw a line, from the state of the line can see the Dyne value of the protective film is what. Generally speaking, there are three kinds of test results. One is that the lines are evenly distributed and there is no water point, which indicates that the Dyne value of the protective film surface is higher than or equal to the value marked on the Dyne pen; If the line is slowly shrinking, it means that the Dyne value on the surface of the protective film is lower than but close to the Dyne value marked on the pen; There is also the case that the lines immediately shrink and become water points, which means that the Dyne value of the protective film is much lower than the Dyne value marked on the pen.

The Dyne value of the protective film actually refers to the strength of the adsorption force of the surface of the protective film, the higher the Dyne value, on behalf of the adsorption force of the protective film is stronger, the concept of Dyne value generally exists in the coating industry and printing industry, higher Dyne value, stronger adsorption force, can make us coated glue or printing ink can better adsorption on the surface of the protective film, It is not easy to drop glue or ink in the later period.