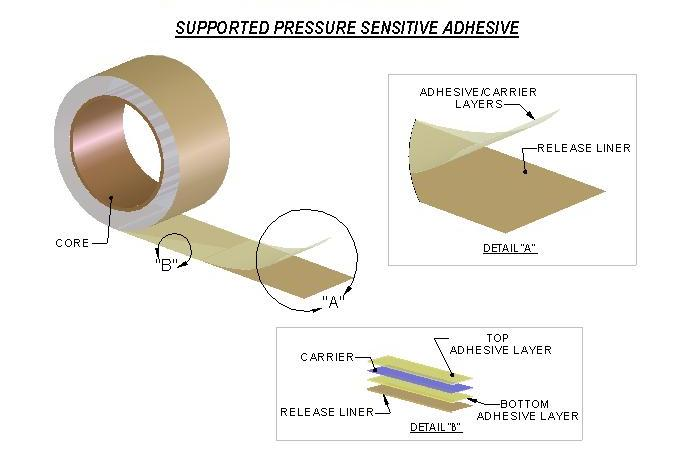

Recently, there has been an increase in the use of pasted surface finishing materials with pressure sensitive adhesives (PSA), such as interior/exterior materials for buildings, interior design materials, advertising materials, etc. Conventional oil-based adhesives discharge residual solvents into the air for a long time after construction. As a result, residents of buildings suffer from symptoms such as headaches, eye, nose and throat irritation, cough, itching, dizziness, fatigue, reduced concentration and when exposed to such residual solvents for a long time, suffer sick house syndrome, which causes respiratory diseases, heart disease, cancer and so on.

For these reasons, water-based emulsion pressure-sensitive adhesives using water as a dispersion medium, which are environmentally friendly and do not emit harmful substances, have received widespread attention and are rapidly replacing conventional oil-based adhesives. Because the viscosity of the adhesive is independent of the molecular weight of the polymer, this water-based emulsion pressure-sensitive adhesive can use polymers with higher molecular weight than solvent-based polymers and can have a wide concentration range of solid content.

In addition, water-based emulsion pressure-sensitive adhesives can have low aging resistance, low viscosity, good bonding strength in the low solid content range, and good compatibility with other polymers.

However, due to the use of water as a solvent, this water-based emulsion adhesive has a slow drying rate, low bonding strength against hydrophobic bonding surfaces and non-porous materials, a narrow range of curing agent selection, and an deteriorated initial bonding strength. In addition, water-based emulsion adhesives contain emulsifiers and dispersants, and therefore do not have superior physical properties (e.g., low water resistance) than oil-based adhesives. In particular, because the fabric itself adheres to a lot of dust, water-based pressure sensitive adhesives used for clothing are difficult to have good adhesion properties, and after adhesion, pressure sensitive adhesives adhere to the fabric more often than labels. In particular, it is necessary to develop a pressure-sensitive adhesive that has excellent bonding strength for clothing fabrics while cleanly removing it from the substrate. However, since the two properties are opposite to each other, if the performance of one of them increases, the performance of the other decreases, making it impossible to satisfy both properties.

In addition, pressure-sensitive adhesives are exposed to high temperatures and humidity during transportation and movement in export containers after adhesion to the fabric substrate. During the process, there was a problem of adhesive sticking firmly to the clothing. In the case of conventional water-based pressure-sensitive adhesives used on clothing, the peeling strength rapidly increases to approximately 3 to 5 times the initial peeling strength, resulting in damage to clothing.