The correct storage method of adhesives is very important to maintain their properties and extend their service life.

Here are some common adhesive storage methods and examples:

- Temperature control: adhesives should be stored in the recommended temperature range. Generally, adhesives should be stored in a dry, cool place, away from direct sunlight and high temperatures. Avoid overheating or undercooling of adhesives.

- Sealed storage: The opened adhesive container should be sealed in time to prevent moisture and impurities from the air. When using adhesives, minimize the opening time of the adhesive container and seal it immediately.

- Vertical storage: The adhesive container should be stored vertically to prevent the outflow or leakage of the adhesive. Make sure the lid of the container is tight to prevent gas or liquid leakage.

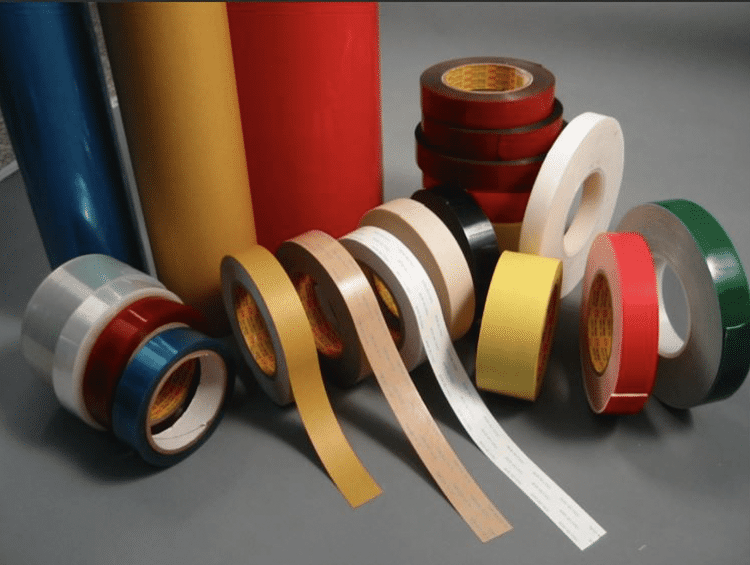

- Classification storage: According to the type, nature and frequency of use of adhesives, different types of adhesives are classified and stored. Avoid contact between different types of adhesives to prevent cross contamination.

- Keep clean: The storage area should be kept clean and away from sources of pollution and chemicals. Avoid storing with corrosive substances, solvents or other chemicals.

Example: A manufacturing company used the following measures when storing adhesives:

– Set up a special storage area: The company has set up a special storage area in the factory to prevent adhesives from mixing with other chemicals and to ensure that the area is dry and clean.

– Temperature and humidity control: The storage area is equipped with temperature and humidity control equipment to ensure that adhesives are stored under appropriate environmental conditions. The temperature is kept within the recommended range and the humidity is controlled at a low level.

– Regular inspection and cleaning: Check the tightness and condition of the adhesive container regularly to ensure that the lid of the container is tight and free of damage or leakage. Clean the storage area regularly and keep it clean.

With proper storage methods, the company has managed to maintain the quality and performance of the adhesive, reduce waste and loss, and ensure the smooth running of the production process.