Yes, customers often struggle with whether to purchase protective films with release liners. Here are some factors to consider that can help customers make a decision:

1. Convenience of use: Protective films with release liners can be easily peeled off and removed without the need for additional tools or machines. This makes it easier to remove the film after use, reducing the complexity of the process.

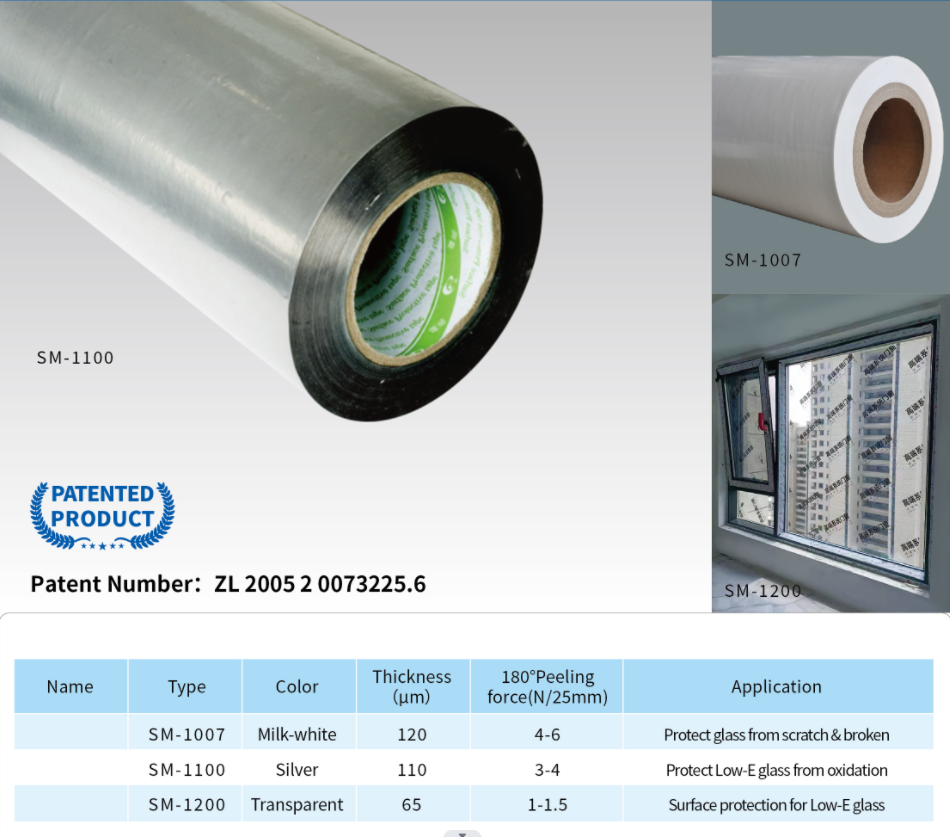

2. Protection effectiveness: Release liners can provide better protection, preventing scratches, contamination, and damage. They can safeguard the surface of the items during transportation, installation, or use, ensuring that the items maintain a good appearance before use.

3. Transparency: Protective films with release liners typically have high transparency and do not affect the appearance of the items. This is particularly important in situations where the appearance of the items needs to be showcased, such as display samples or sales exhibitions.

4. Cost factors: Protective films with release liners are generally relatively more expensive because additional processes and materials are involved in their manufacturing. Customers can weigh the cost and benefits based on their budget and protection requirements.

5. Application environment: Determine whether a release liner is needed based on the specific application environment and usage requirements. If the protected items need long-term protection with the film during use, a release liner may be more important.

Customers should consider the above factors when purchasing protective films and make the most suitable choice based on their own needs and budget. If the protection requirements are relatively simple or cost limitations are high, choosing a protective film without a release liner is also an option to consider.