When removing the protective film from the edges of Low-E glass, it is essential to ensure that no adhesive residue remains on the glass surface. To achieve this, the following measures can be taken:

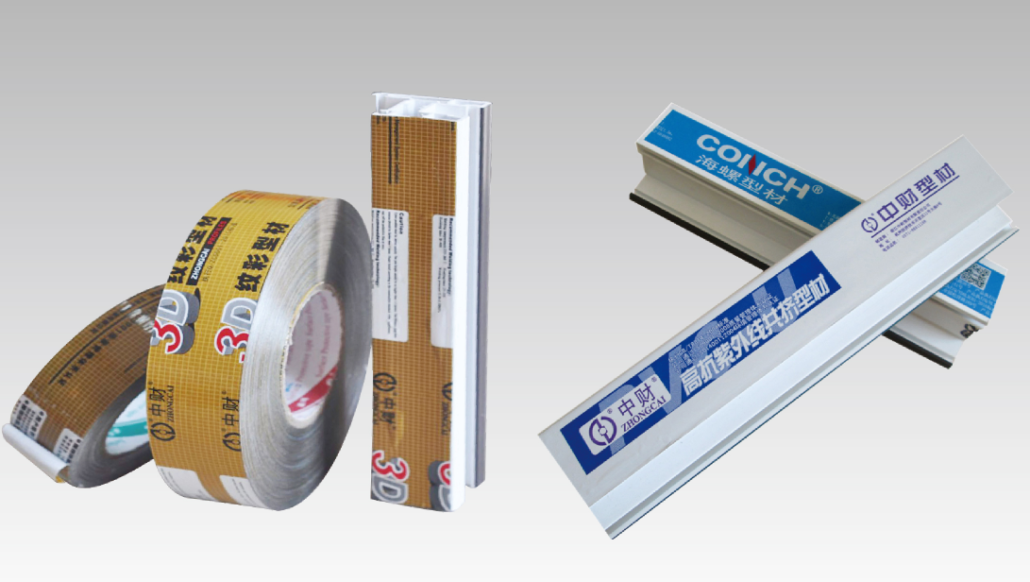

1. Selecting suitable adhesive: When manufacturing the protective film, it is crucial to choose an adhesive with low viscosity and easy peeling properties. This will minimize the likelihood of adhesive residue remaining on the glass during the film removal process.

2. Controlling the amount of adhesive applied: The adhesive should be applied evenly and in moderation, avoiding both excessive and insufficient quantities. Ensuring a thin and uniform adhesive layer can reduce the potential for residue.

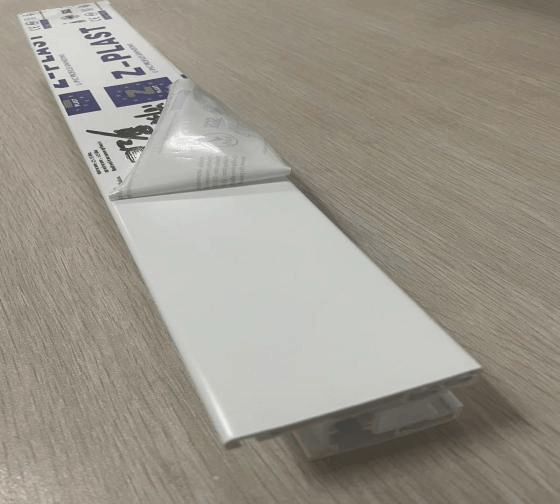

3. Paying attention to film removal techniques: When removing the film, it is essential to follow a specific angle and direction, maintaining a consistent and stable force. Avoid applying excessive or rapid force to minimize the possibility of stretching or tearing the adhesive, which could lead to residue.

4. Using assistive tools: Specialized film removal tools or blades can be utilized to gently scrape along the edges of the protective film or the boundaries of the adhesive. This can assist in removing residual adhesive.

5. Cleaning the glass surface: After removing the film, it is recommended to use a cleaner and a soft cloth to wipe the glass surface, removing any residual adhesive or dirt.

Please note that specific operating methods may vary depending on the type of protective film and the nature of the adhesive used. Therefore, it is advisable to refer to the protective film’s instructions or consult a professional to ensure the correct and safe removal of the film while avoiding adhesive residue.