Different application areas need to choose the right protective film to meet their specific needs and requirements.

The following are some common application areas and corresponding protective film choices:

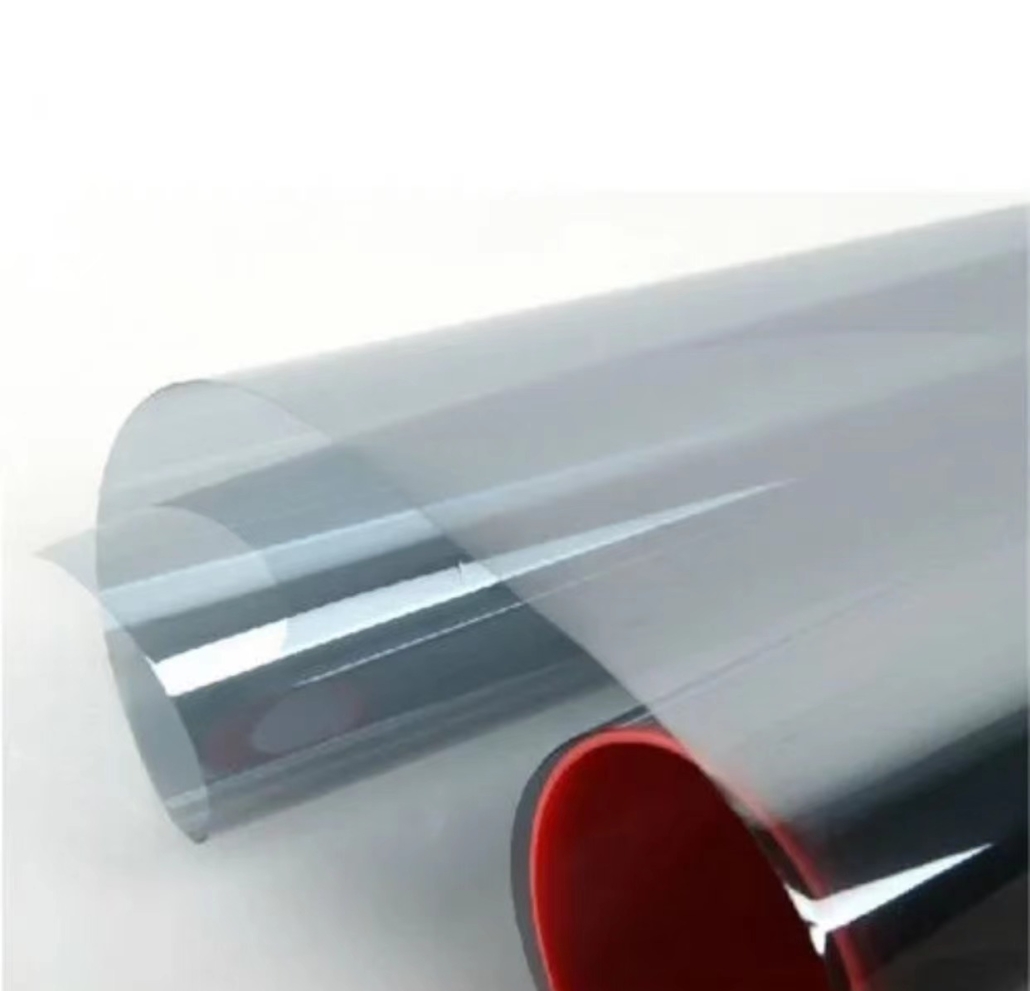

1. Automotive industry: Automotive protective film is usually used to protect the body surface from external damage such as scratches and stones. In this application, common protective films include body film, car window film, and radiator film. These films usually have high wear resistance, scratch resistance, and UV protection.

2. Electronic products: In the field of electronic products, commonly used protective films include screen protective films, touchpad protective films, and surface protective films. These films are often required to have characteristics such as high light transmission, wear resistance, and anti-fingerprint to protect the screens and surfaces of electronic products from scratches, stains, and fingerprints.

3. Building and glass: In the field of building and glass, commonly used protective films include window protective films, explosion-proof films, and anti-ultraviolet films. These films are usually required to have characteristics such as high light transmission, weather resistance, and UV protection to protect glass Windows from the effects of sun exposure, scratches, and cracks.

4. Packaging and transportation: In packaging and transportation, protective films are usually used to protect items from moisture, dust, extrusion, and damage. These membranes are usually required to have properties such as tear resistance, water, and moisture resistance, and to provide safety and stability of the item.

5. Agriculture and agricultural products: In the agricultural field, the commonly used protective film includes agricultural film, mulching film, and fruit protective film. These membranes are often required to have properties such as UV resistance, frost resistance, and insect protection to protect plants and produce from natural conditions, pests, and pathogens.

These are just some of the common application areas and the corresponding protective film options. When selecting a protective film, it is necessary to consider the specific application requirements, material characteristics, environmental impact, and other factors to ensure that the selected protective film can effectively protect and meet the needs.

If you are interested in our products, please feel free to contact us!