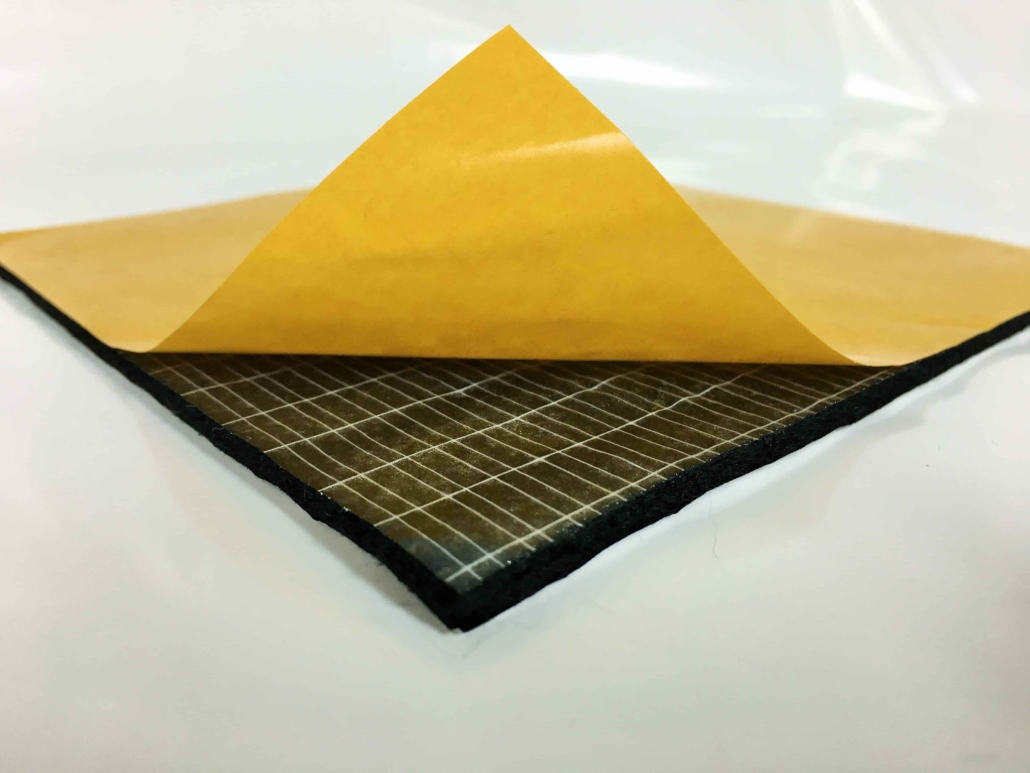

For protective films applied on rough surfaces, higher adhesive requirements are usually needed to ensure the film adheres firmly to the surface and provides effective protection.

Here are some considerations for adhesive requirements for protective film on rough surfaces:

1. Strong Adhesion: Rough surfaces typically have more irregularities, so the protective film requires strong adhesion to prevent it from peeling or loosening during transportation, handling, and installation.

2. Filling Capability: The protective film needs to have a certain filling capability to cover and fill the depressions and uneven parts on the rough surface, providing a uniform protective layer.

3. Adaptability: Rough surfaces can have various shapes and textures, and the protective film should possess strong adaptability to closely fit the surface and cover all the detailed parts.

4. Abrasion Resistance: As rough surfaces are prone to abrasion and scratching, the protective film requires good abrasion resistance to prevent surface damage.

5. Temperature Resistance: Rough surfaces may be exposed to different temperature environments, and the protective film needs to have good temperature resistance, ensuring it does not deform or detach due to temperature changes.

6. Tear Strength: Rough surfaces can exert a greater pulling force on the protective film, so the film needs to have sufficient tear strength to prevent tearing or damage.

In practical applications, to meet the adhesive requirements for protective film on rough surfaces, special adhesives with high adhesion and durability are often chosen to ensure the film effectively adheres to the surface and remains stable during use. Additionally, adjusting the film thickness and coverage method can enhance the film’s adhesion and filling capability.

If you are interested in our products, please feel free to contact us!