Poor quality protective film may have a series of defects and problems, these problems may lead to the protective film can not provide effective protection, and may even cause damage to the protected object.

The following are some of the features that an inferior protective film may have:

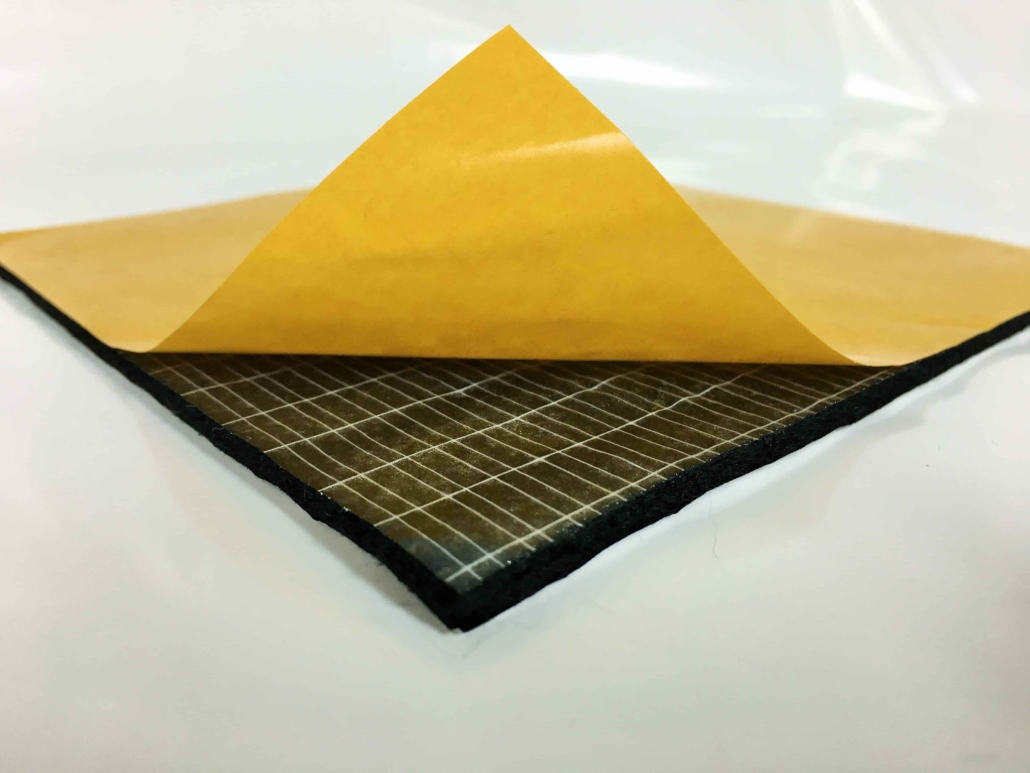

- Unstable viscosity: Poor quality protective film may have unstable viscosity, may be too sticky or too weak, resulting in the protective film can not be effectively attached to the protected object, or can not be easily removed.

- Easy to tear: the low-quality protective film may be easy to tear when torn, resulting in residue at the tear, or can not be completely torn.

- Deformation and shrinkage: poor quality protective film may become easy to deform, fold or shrink under temperature changes, affecting the appearance and performance.

- Sticky residue: poor quality protective film may leave adhesive or sticky residue after removal, causing the surface of the protected object to become dirty or difficult to clean.

- Vulnerable: Low-quality protective films may be vulnerable to scratches, wear, or tears during transportation, installation, or use.

- Easy to fade: poor quality protective film may fade or lose transparency when exposed to ultraviolet light, affecting the appearance of the protected object.

- Temperature resistance: poor quality protective film may lose viscosity in high or low-temperature environments, affecting the protection effect.

- Low transparency: The transparency of the protective film is not good, which may affect the appearance and visibility of the protected object.

- Chemical reaction: Poor quality protective film may be sensitive to chemicals in the environment, resulting in material deterioration, discoloration, or damage.

- Safety concerns: Low-quality protective films may contain hazardous substances that may pose a potential threat to health and the environment.

- Construction problems: the poor quality protective film may be difficult to paste flat in the construction process, resulting in bubbles, wrinkles, or other construction problems.

In short, poor quality protective film may have viscosity problems, easy to tear, deformation, easy damage, and other characteristics, these problems may affect the function and performance of the protective film, and may even cause damage to the protected object. Choosing a high-quality protective film can ensure effective protection of the protected object and extend its service life.

If you are interested in our products, please feel free to contact us!