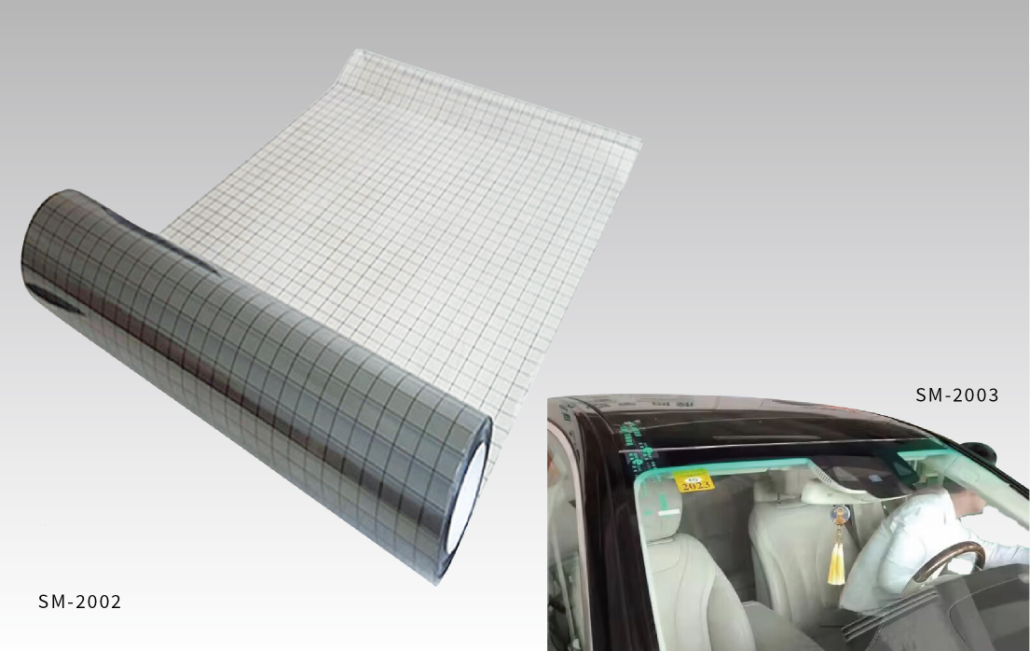

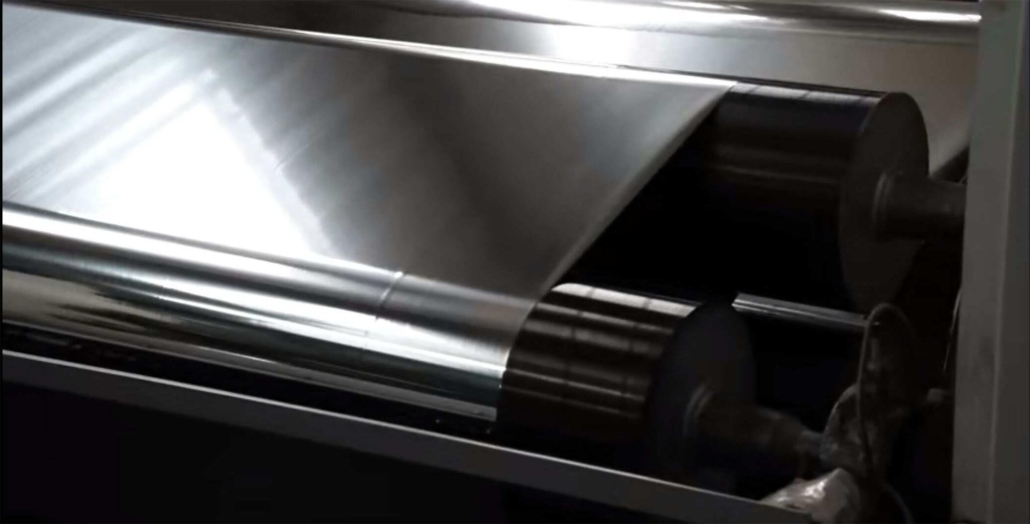

The heat-resistant ultra-low stripping force protective film is a high-performance packaging material for electronic devices with the following characteristics:

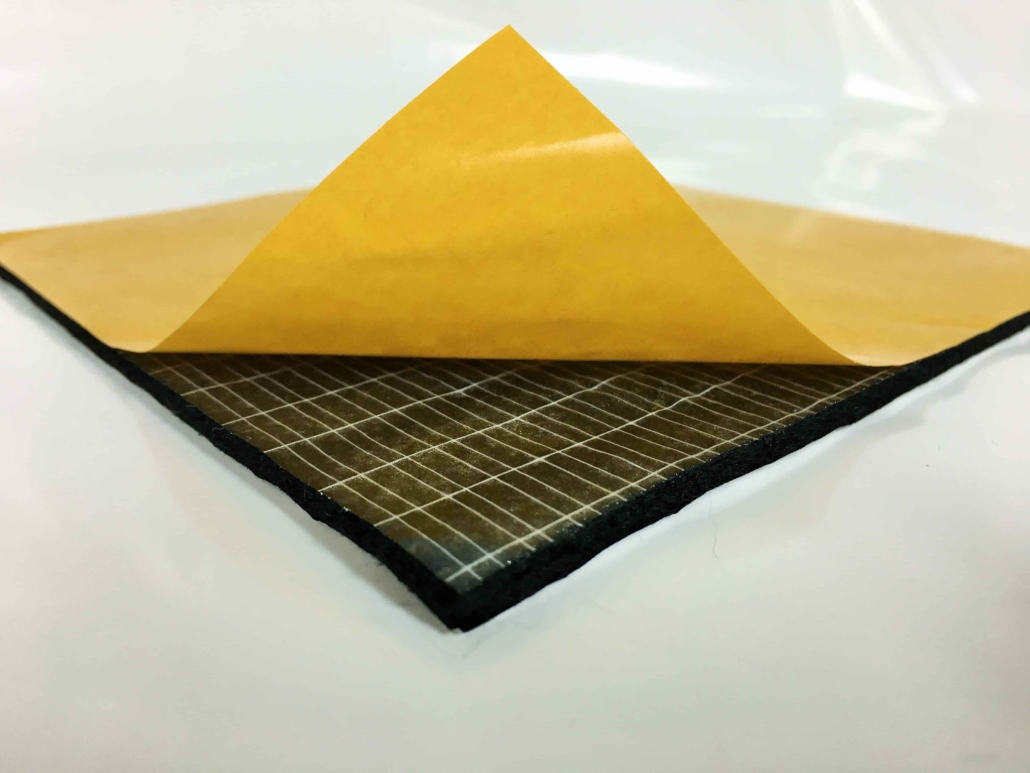

- Ultra-low stripping force: the protective film can maintain ultra-low stripping force under high-temperature conditions, reducing the damage when the component is separated.

- High heat resistance: the protective film has good thermal stability under high-temperature conditions and can withstand oxidation and aging process under high-temperature environments.

- Excellent electrical performance: The protective film has excellent electrical properties, such as high insulation resistance, low dielectric constant, etc., which can ensure the normal operation of electronic devices.

- Good chemical resistance: the protective film can withstand the corrosion of a variety of chemicals and solvents, and can maintain its stable performance for a long time.

For example, in the production of electronic devices, protective films are widely used in chip packaging, lead welding, circuit board assembly, and other links. Ultra-low stripping force ensures stability when components are separated, while high heat resistance and good electrical performance guarantee high performance and reliability of electronic devices.

If you are interested in our products, please feel free to contact us!