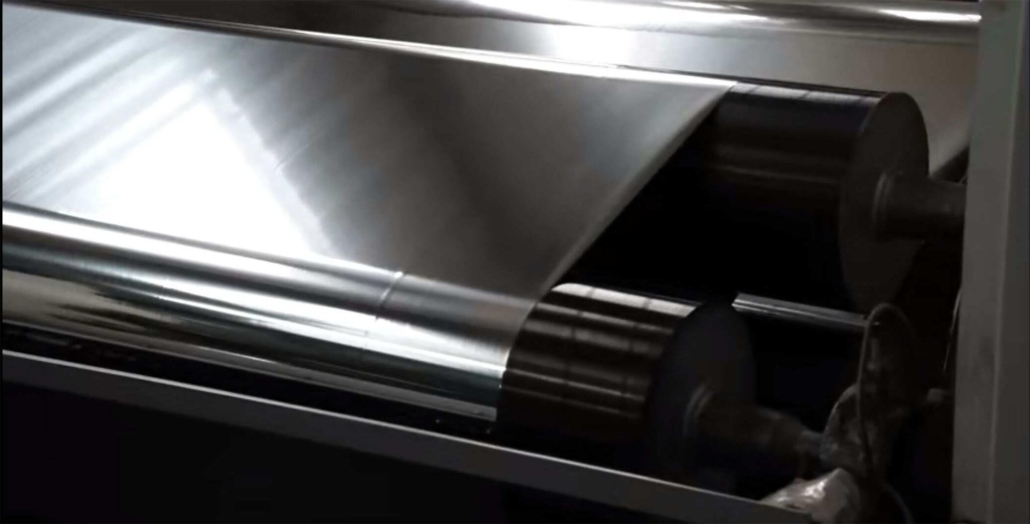

Polyvinyl chloride (PVC) protective film is suitable for industrial applications that protect surfaces from various problems. It is a temporary film that offers several advantages to industries. However, it is wise to know more about PVC protective films before buying them from a manufacturer or supplier. This will help industries meet their requirements during the production process. PVC protective films are available in standard thicknesses tailoring to the needs of users.

What are the advantages of using PVC protective films for industrial applications?

- Durability

A PVC protective film is highly durable and will enhance the lifespan of surfaces to a greater extent. It exhibits exceptional resistance to surfaces, thereby showing ways to protect them from corrosive chemicals, abrasion, shock, etc. Furthermore, it is ideal for medium- to large-term applications that help reduce unwanted problems.

- Fire resistance

PVC protective films are highly resistant to fire due to their high chlorine content. They don’t ignite easily or produce excess heat when burned. On the other hand, industries should choose eco-friendly products because they can emit harmful chemical agents while melting.

- Non-conductivity

Another advantage of using a PVC protective film is that it doesn’t conduct electricity. It acts as an insulator in industrial and mechanical components to overcome risks. Industries can choose high-quality films that cater to their requirements.

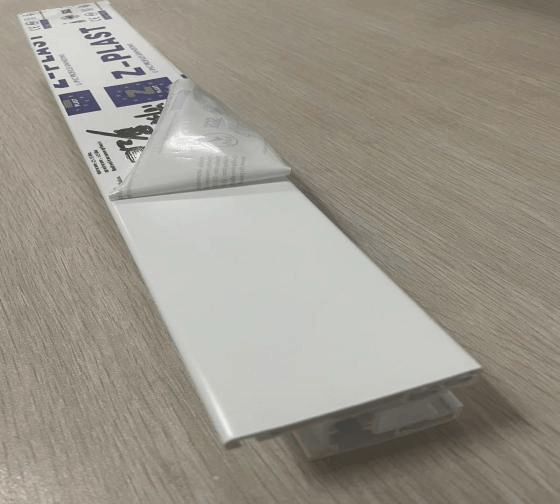

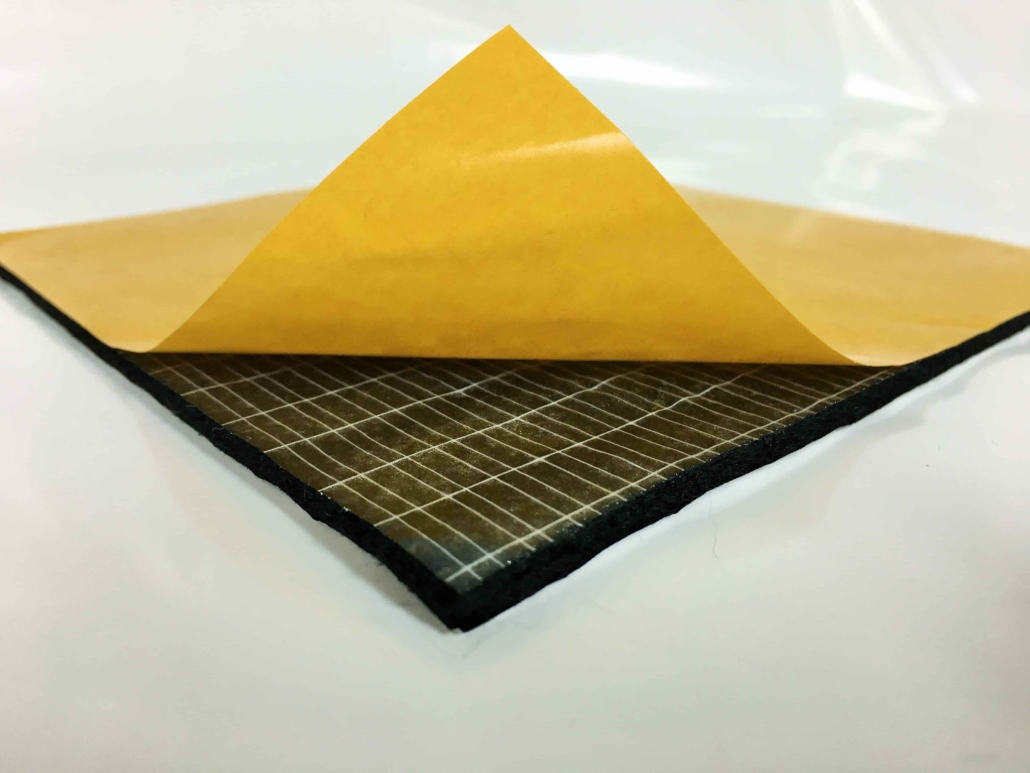

- Easy to apply and remove

PVC protective films are easy to apply to surfaces, and you can remove them at any time without any hassle. Since they are self-adhesive, industries can utilize them anywhere as soon as possible.

- Transparency

Some PVC protective film products are transparent and cater to the needs of surfaces where visibility is important. Aside from that, they provide ways to improve the texture and natural appearance of surfaces with high efficiency.

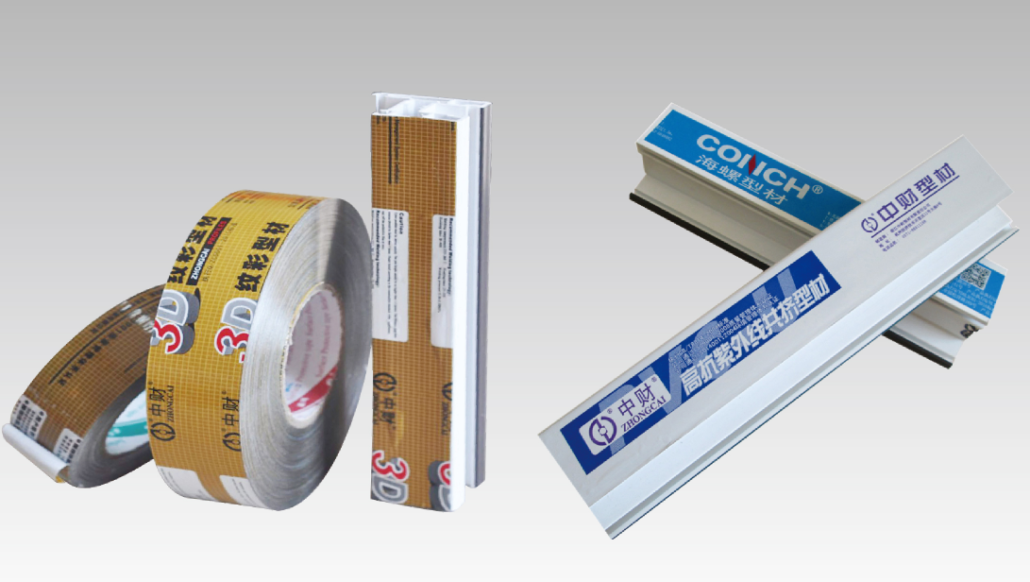

- Versatility

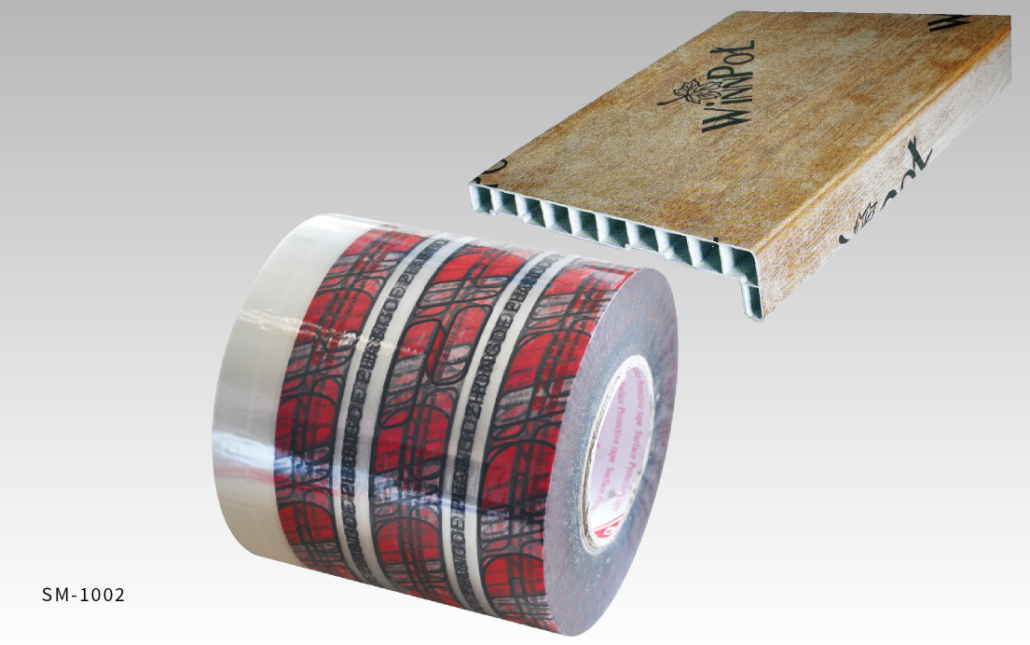

PVC protective films are versatile and can be used for a variety of applications in industries, which help achieve the desired outcomes. At the same time, industries should select films after conducting complete research.

- Serves as a protective layer

Using PVC protective films enables industries to protect surfaces from contamination, dirt, dust, scratches, and other problems. The films serve as a protective layer on surfaces and show ways to enhance their lifespan.

- Flexibility

A PVC protective film offers more flexibility to users by addressing their needs during the installation process. However, industries should ensure that it is compatible with the surfaces and meets the standards.

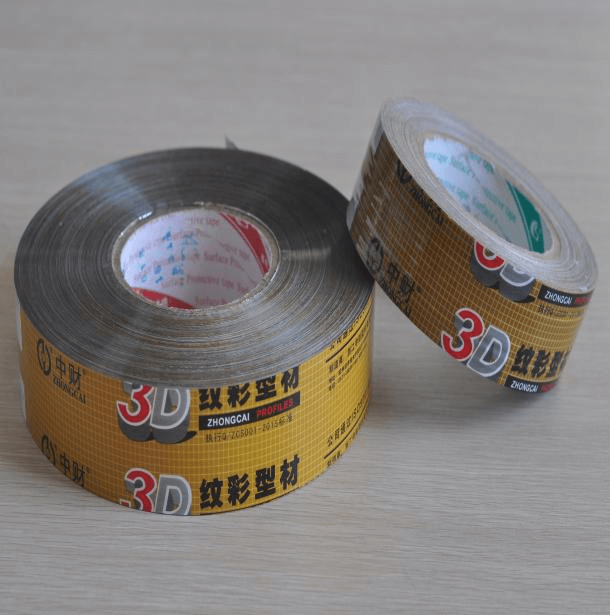

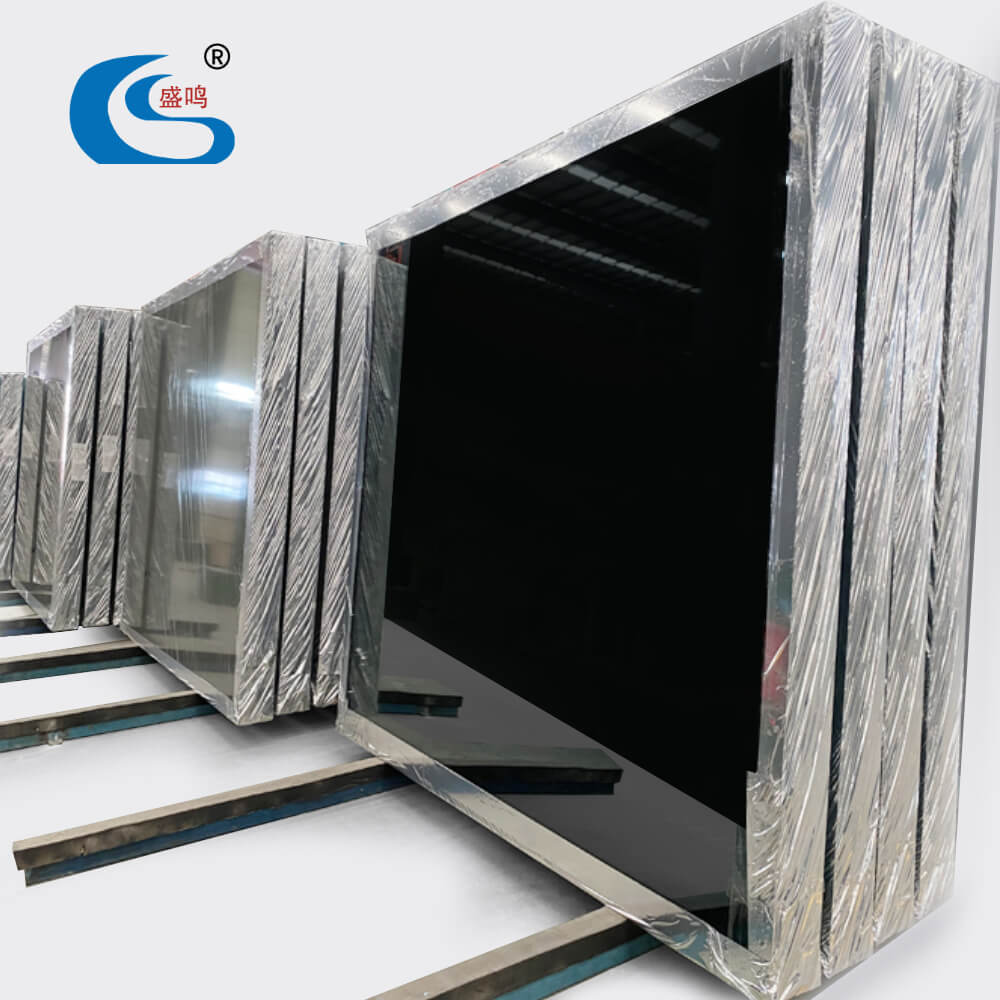

Where to order high-quality PVC protective films?

Those willing to order high-quality PVC protective films should pick a reputed manufacturer in the market. Wuxi Changsheng is a leading PVC protective film producer that offers several products for industrial applications and other purposes. It provides methods to select films at the best prices.

The company provides methods to search for the best PVC films online to accomplish goals in the manufacturing process. Industries and others can send their requirements to the company online. The PVC films offered by the company are eco-friendly, which will reduce the environmental impact.