Advantages and Challenges of BOPA for Low-E Glass Edge Protection

Regarding the use of BOPA material for the edge protection film of Low-E glass, it is essential to first understand some of the fundamental characteristics of BOPA.

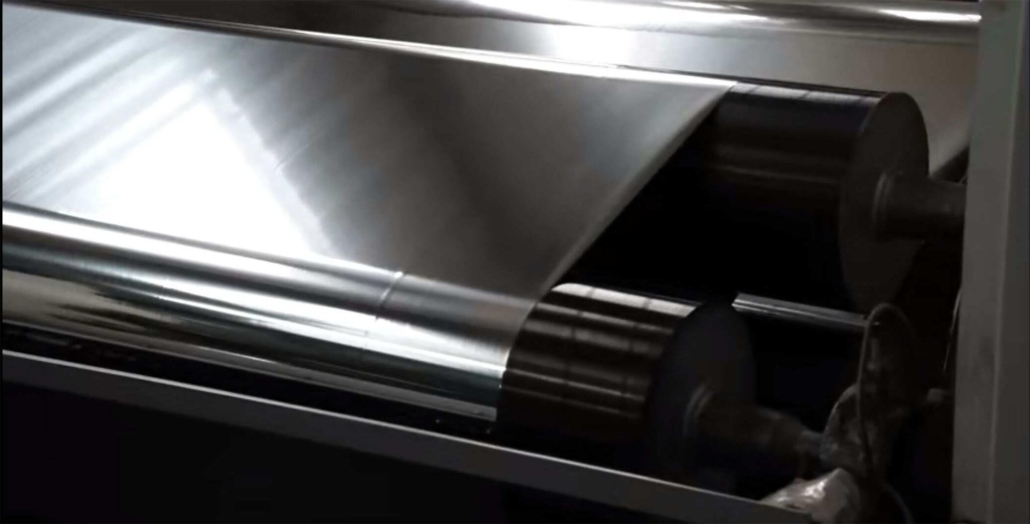

BOPA, also known as bidirectional-oriented nylon film, exhibits high strength, excellent toughness, and puncture resistance, along with good transparency and gloss. Furthermore, its superior gas barrier properties, including oxygen and water vapor, are particularly crucial for safeguarding the edges of Low-E glass.

The primary advantage of using BOPA as an edge protection film for Low-E glass lies in its exceptional performance. Thanks to its high strength and wear resistance, BOPA effectively shields the edges of Low-E glass from damage and scratches. Simultaneously, its superior gas barrier properties efficiently prevent the impact of external gases on the glass, thereby maintaining its performance and appearance.

Moreover, BOPA material boasts excellent processability, allowing for coating, metallization, or lamination with other substrates. This versatility opens up possibilities for producing Low-E glass edge protection films with specific functionalities. For instance, applying specific coatings can enhance the film’s weather resistance or UV resistance.

However, it’s worth noting that BOPA material poses some challenges in terms of moisture absorption and solvent residue. Strict humidity control is necessary during printing and lamination to prevent moisture absorption and deformation. Additionally, careful selection of inks and solvents is crucial to minimize residual solvents and avoid any adverse effects on Low-E glass.

In summary, BOPA material presents a promising option for Low-E glass edge protection film due to its superior performance and good processability. It meets the requirements for protecting the edges of Low-E glass effectively. Nevertheless, addressing challenges such as moisture absorption and solvent residue remains crucial to ensuring the quality and performance of the protective film in practical applications.

Leave a Reply

Want to join the discussion?Feel free to contribute!