Analyze the role of floor protection film

Floor protection film is a material used to protect the surface of the floor, usually a thin film or coating that can be applied to the floor to prevent damage, contamination, and wear. This protective film is typically used after the floor is installed or on special occasions such as construction, renovation, moving, etc., to temporarily protect the floor from factors like scratches, dirt, liquid penetration, and more.

The primary functions of floor protection film include:

- Scratch and wear prevention: Floor protection film can reduce scratches and wear caused by furniture, shoes, and other items, extending the lifespan of the floor.

- Waterproof and dirt-resistant: It can prevent liquids from seeping beneath the floor, preventing discoloration or damage. Additionally, it can block dust, dirt, and other contaminants from entering the tiny pores of the floor.

- Easy cleaning: Floor protection film is typically easy to clean, allowing for quick wiping or scrubbing and reducing the maintenance workload.

- Safety: Some floor protection films have anti-slip properties, improving the safety of the floor, especially in wet environments.

- Easy removal: Floor protection film is usually removable, making it easy to peel off when needed without leaving residue or damaging the floor surface.

Floor protection film can be used on various types of flooring, including hardwood, tile, laminate, carpet, and more. They are highly useful in construction sites, home renovations, exhibitions, moving, and other situations where floor protection is required. Different types of floor protection films have different characteristics, and you can choose the appropriate type based on your specific needs.”

For spray painting, what type of floor protection film is needed? When protecting the floor during spray painting, it is typically necessary to choose a specific type of floor protection film to prevent damage from paint pigments and solvents.

For spray painting jobs, the following types of floor protection films are recommended:

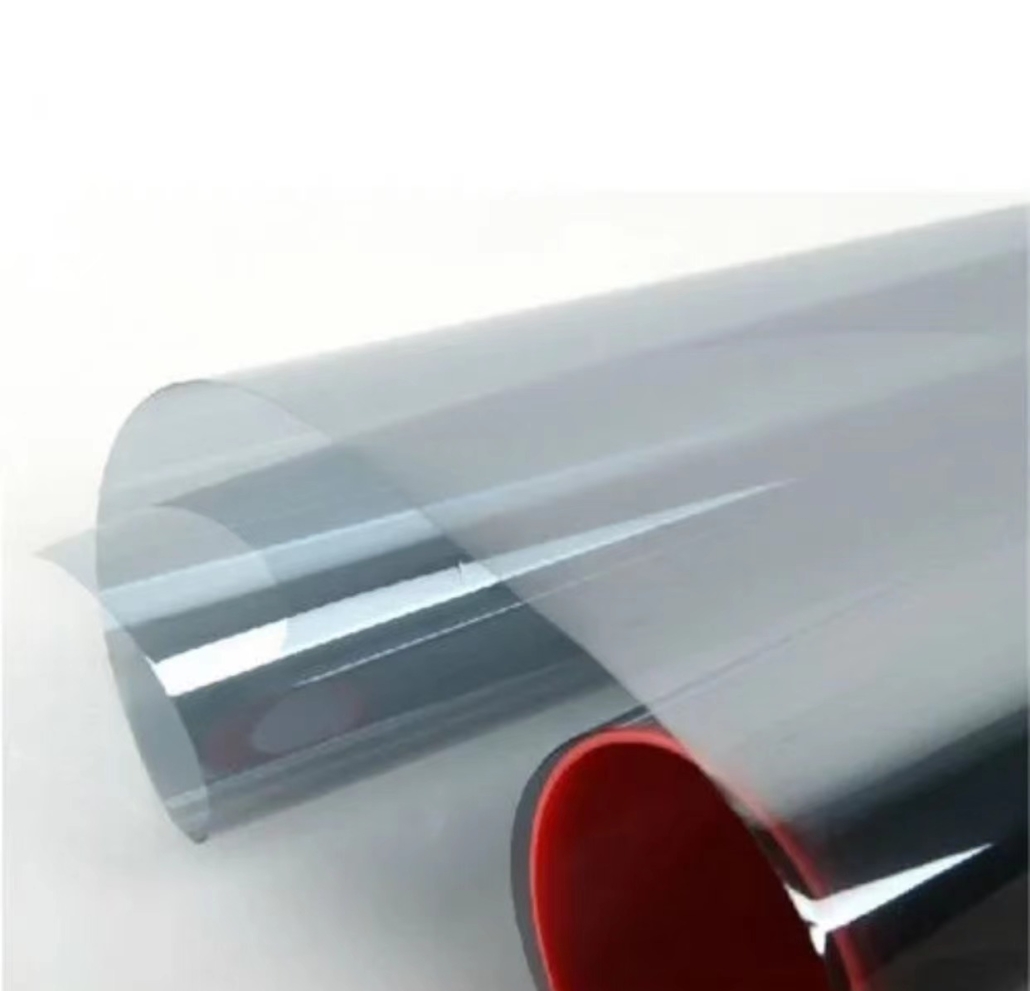

- Transparent plastic film: This type of film is usually made from polyethylene or polypropylene and is transparent. It can completely cover the floor surface and provides excellent protection against liquids and paint while allowing you to see the floor’s condition. These films are typically easy to apply and remove without leaving residue.

- Adhesive-backed film: These films have a layer of adhesive on the bottom, allowing them to adhere to the floor and prevent shifting or sliding during the painting process. This type of protection film offers a more secure protection as it is less likely to be accidentally removed or moved. However, care should be taken when removing it to avoid leaving adhesive residue.

- Paper-backed film: These floor protection films have a paper backing similar to tape. You can roll them out onto the floor, and the paper backing helps keep the film in place and makes it easier to remove when needed. This type of film is often suitable for larger surfaces, such as at exhibitions or construction sites.

When choosing a floor protection film for spray painting, consider the following factors:

- Floor-type: Ensure that the selected film is suitable for your type of flooring to prevent damage or staining.

- Type of paint: Different types of paint (e.g., water-based, oil-based, clear coats) may require different protection films due to variations in chemical properties and solvents.

- Expected duration: Consider how long you need to protect the floor to determine whether you need temporary or long-term protection.

- Safety: Ensure that the chosen film does not make the floor slippery, especially in wet conditions.

When using floor protection film, follow the manufacturer’s guidelines to ensure the best results and prevent any potential damage. Additionally, regularly check the film’s condition to maintain the integrity of the floor.”

For transportation, what type of floor protection film is needed? When transporting flooring materials, it is generally necessary to use a specific type of floor protection film to ensure that the flooring remains undamaged and uncontaminated during transit.

The following are common types of protective films used during transportation:

- Surface protection film: This type of floor protection film is typically a transparent thin film that can cover the surface of the floor to protect it from scratches, dirt, and minor abrasions. It can be used on various types of flooring, such as hardwood, tile, and laminate. Transparent film allows you to inspect the floor’s condition while providing protection.

- Foam-backed floor protection film: This film has a built-in foam cushion layer that provides additional impact absorption protection, preventing the floor from being damaged during transport due to bumps or impacts. Foam-backed floor protection film is particularly suitable for fragile or easily damaged flooring materials.

- Adhesive-backed floor protection film: This type of film has a layer of adhesive on the bottom, allowing it to adhere to the floor and prevent the film from sliding or coming off during transportation. This design ensures that the protective film stays securely in place and doesn’t shift during transit.

- Paper-backed floor protection film: These films have a paper backing similar to tape, making them easy to roll out onto the floor. The paper backing helps maintain the film’s position and facilitates easy removal when necessary. This type of film is often used for larger surfaces, such as at exhibitions or construction sites.

When selecting a floor protection film for transportation, consider the following factors:

- Floor-type: Ensure that the chosen film is suitable for the type of flooring you are transporting to prevent damage.

- Transportation conditions: Consider the distance, mode, and conditions of transportation to determine the required level and type of protection.

- Budget: Different types of protective films have varying prices, so budget constraints should be taken into account.

- Ease of use: Choose a protective film that is easy to install and remove to improve efficiency during transportation.

When transporting flooring materials, make sure to properly install and secure the protective film to ensure adequate protection for the floor during transit. Additionally, regularly check the condition of the floor protection film, especially for longer transportation periods, to ensure its effectiveness.

If you are interested in our products, please feel free to contact us.

Leave a Reply

Want to join the discussion?Feel free to contribute!