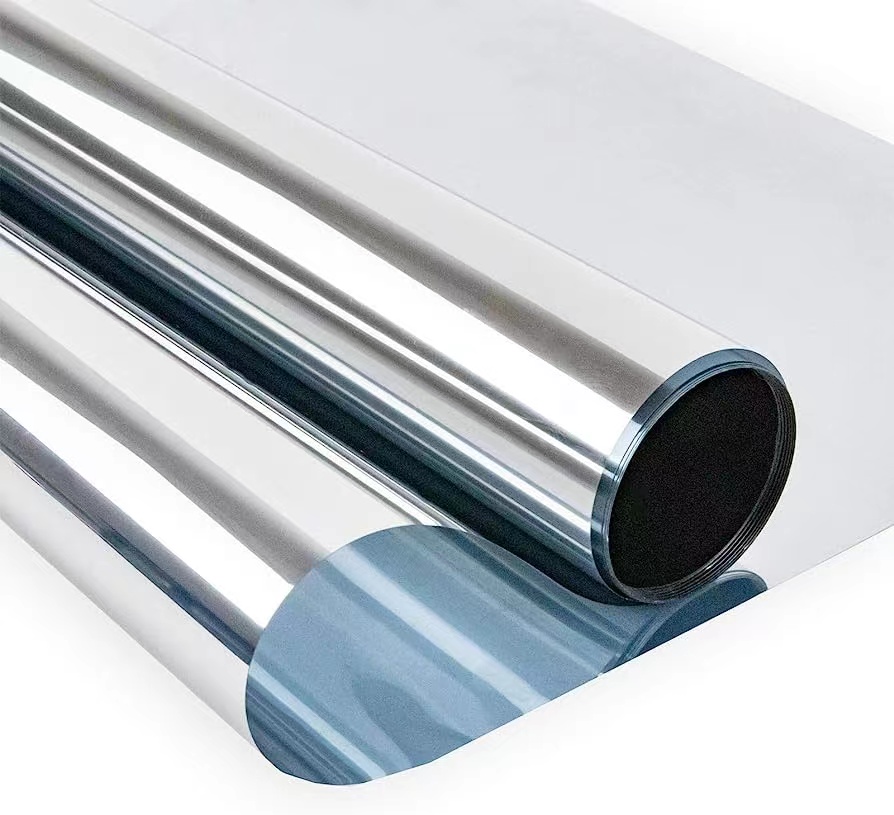

Production Process of Aluminum-coated Film

The production process of aluminum-coated film involves a series of steps.

Here are the basic steps typically used in the production of aluminum-coated film:

- Cleaning and preparing the glass substrate: Firstly, the glass substrate needs to undergo cleaning and surface preparation to remove dirt and impurities and ensure a smooth and clean surface.

- Substrate pre-treatment: Next, the substrate goes through pre-treatment steps, including surface activation treatment and chemical treatment. These steps help improve the adhesion and uniformity of the coating.

- Coating preparation: Before preparing the aluminum-coated film, the aluminum coating material needs to be prepared. One common method is to evaporate or sputter the aluminum material onto the specific substrate in a vacuum environment.

- Aluminum coating preparation: When preparing the aluminum coating, it is typically deposited on the substrate surface under specific process conditions. This can be achieved through methods like physical vapor deposition (such as evaporation, sputtering) or chemical vapor deposition (such as chemical vapor deposition, thermal decomposition).

- Coating protection: After the aluminum coating is deposited, it often requires the application of a protective layer to improve its corrosion resistance and durability. This can be achieved by applying a transparent protective layer.

- Inspection and packaging: Lastly, the prepared aluminum-coated film undergoes inspection and quality control to ensure it meets the requirements. Subsequently, the film is cut, trimmed, and properly packaged for transportation and use.

It is important to note that the production process of aluminum-coated film may vary depending on the manufacturer and specific application. The above steps represent a general preparation process, and the actual production process may differ due to variations in materials, equipment, and process conditions.

If you are interested in our products, welcome to contact us.

Leave a Reply

Want to join the discussion?Feel free to contribute!