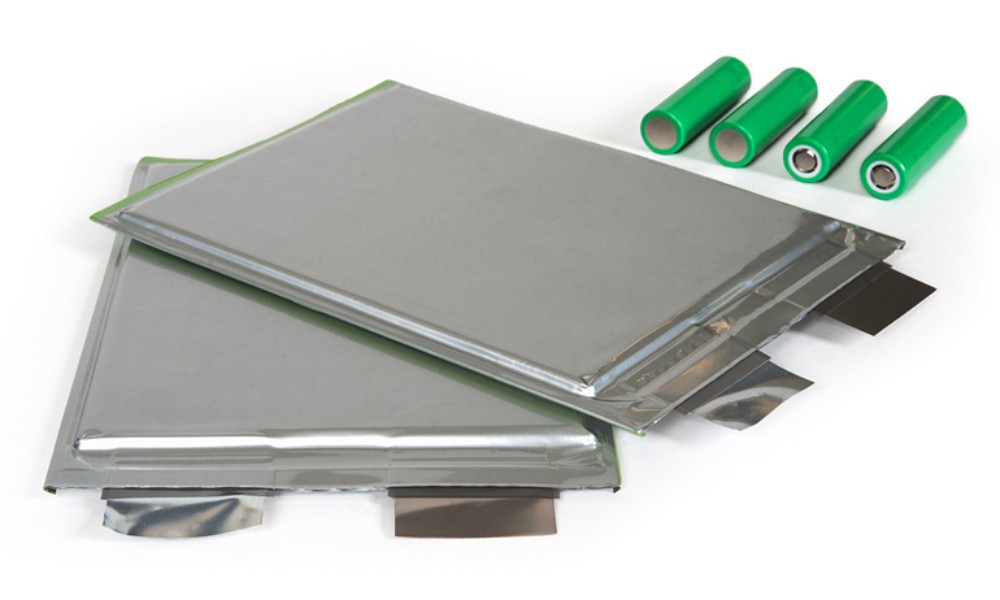

Adhesives required for the lithium battery market

In the manufacturing process of lithium batteries, adhesives play an important role in fixing and connecting different components to provide structural support and protection for the battery.

Here are some of the adhesives that the lithium battery market may need and their applications:

- Conductive adhesive: used for the connection of battery connecting pieces, battery pole pieces, battery housing, and other components to ensure the conduction of current.

- Insulating adhesive: used for insulating isolation between battery components to prevent short circuits and electrical interference between battery components.

- Heat guide adhesive: used between the battery component and the heat sink to promote the heat conduction and heat dissipation of the battery and improve the stability and life of the battery.

- Sealant: Used in the battery assembly process to ensure the tightness of the battery shell and prevent liquid leakage inside the battery.

- Structural support adhesive: used to fix the position of the battery component to enhance the mechanical strength and stability of the battery.

- Bonding adhesive: used for bonding between battery components, such as battery cover plate, battery pole plate, etc.

- Penetration adhesive: used for tight connection of battery components to improve battery performance and life.

- High-temperature adhesive: used to maintain the performance of the adhesive in a high-temperature environment to meet the requirements of the battery under high-temperature working conditions.

- Low-temperature adhesive: used to maintain the performance of the adhesive in a low-temperature environment to meet the requirements of the battery under low-temperature working conditions.

- Chemical-resistant adhesive: used to protect the battery components from the erosion of chemical substances inside the battery.

The types and applications of lithium batteries are wide, so the demand for adhesives also varies by application. When choosing an adhesive, it is necessary to choose according to the type of battery, working environment, and performance requirements. At the same time, because lithium batteries have certain safety risks, it is also very important to ensure that the selected adhesive meets the relevant safety standards.

If you are interested in our products, please feel free to contact us.

Leave a Reply

Want to join the discussion?Feel free to contribute!