Classification of environmentally friendly adhesives

Solvent-free adhesive

(1) Solvent-free adhesive, also known as reactive adhesive, is the two components that can be chemically reacted are respectively brushed on the surface of the bonded material, and the components are in close contact under certain conditions to achieve the purpose of chemical reaction crosslinking. The two components must have strong adhesion to their respective adhesives, and reaction time, pressure, temperature, and other technological factors are appropriate. It is reported that a new single-component solvent-free sealant with low molecular mass polyisobutylene polymer as the main body and prepared with various additives is developed in our country. The rubber is cheap, easy to construct, has good weather resistance and permanent bonding performance, and can ensure the sealing between the auto sheet metal and the rubber seal strip. Another kind of non-polluting two-component polyurethane adhesive with good bonding performance, low-temperature curing, and low cost solves the problem of low-temperature curing difficulty. Solvent-free adhesive solvent-free volatilization does not cause pollution, of course, should also be used in the process of no harmful small molecule release. At present, this adhesive mainly consists of hot melt adhesive. This kind of adhesive has no pollution, fast curing, wide bonding surface, is suitable for continuous production, and easy storage, and transportation.

Water-based adhesive

(2) Water-based adhesive is one of the oldest varieties. In ancient times, people used water-soluble polymers containing bone glue, casein, and other natural substances as adhesives. It wasn’t until the early 1960s that the field saw new developments. In recent years, safety and pollution-free, especially solvation-free, have been promoted in the development of water-based adhesives. Water-based adhesives are adhesives that take water as a dispersing medium and are divided into water-soluble adhesives, water-dispersed adhesives, and water-emulsion adhesives, which are a major category of environmental protection adhesives. Water-based adhesive is to take water as the dispersion medium of polymer, when the polymer is soluble in water, called water-soluble adhesive, and when the polymer with the effect of an emulsifier, dispersed in water, is called water emulsion adhesive. The advantages of water-based adhesive are: friendly to the environment, non-toxic, non-combustible, high solid content, available for existing application equipment and equipment is easier to clean. For example, water-based acrylate adhesive modifies water-based acrylate through organosilicon, which can give acrylate emulsion some new properties. In recent years, water-based adhesive environmental protection adhesive has developed rapidly in our country, while the output is growing, product quality is improving, increasing varieties, some high technical content and good performance of adhesives continue to appear, such as cold resistance and water resistance of good latex, scrub resistance, pollution resistance, and water resistance of organically modified acrylic acid building emulsions.

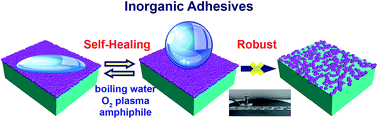

Inorganic adhesive

(3) Inorganic adhesive is a series of adhesives composed of inorganic salts, inorganic acids, inorganic bases, and metal oxides. The inorganic adhesive is a new type of adhesive, and many varieties, according to the curing conditions are divided into gas dry type, water solid type, hot melt type, and reaction type. Inorganic glue is mostly made of a solid and liquid mixture into a paste, raw materials are easy to obtain. The general organic adhesive can withstand high temperatures usually below 100 ℃. Such as latex below 60 ℃, epoxy resin at about 100 ℃, and phenolic resin at about 220 ℃. The inorganic adhesive can withstand the high temperature of 600 ~ 900 ℃, and the improved composition can reach more than 1 800 ℃. Usually water soluble, low toxicity, no combustion, no environmental pollution; The coefficient of thermal expansion is small, only 1/10 of steel, ceramic 1/3; Oil resistance, radiation resistance, no aging, good durability, but not acid, alkali corrosion, water resistance is poor, brittleness is larger, not impact resistance. Can be cured at room temperature, and basically does not shrink, but some slightly expanded. Socket and groove bonding strength is high, and should not be flat. The sleeve tensile shear strength is greater than 100 MPa.

Natural glue and modified natural glue

(4) Natural glue and modified natural glue is the earliest adhesive used by human beings, so far has thousands of years of history, in the development of human society and the historical process, but played a great role in promoting and promoting, such rubber raw materials are easy to obtain, simple production process, convenient use, generally water-soluble, and most non-toxic. There are many varieties of natural adhesives, which can be divided into plant adhesives, animal adhesives, mineral adhesives Marine biological adhesives, etc., and according to the chemical structure can be divided into glucose derivatives, amino acid derivatives, and other natural resin adhesives.

adhesives

Leave a Reply

Want to join the discussion?Feel free to contribute!