Crosslinking modified water-based acrylic pressure sensitive adhesive

The adhesion of PSA is mainly due to the van der Waals force and hydrogen bond formed between PSA and the surface of the bonded substrate. The surface of the bonded substrate has a complete structure and partial electron rearrangement. Aqueous acrylate emulsion has good surface wettability, so the adhesion and initial adhesion of corresponding PSA is relatively good. Generally, the initial adhesion of PSA is improved by reducing the polymer T[(glass transition temperature), but the cohesion strength of PSA will be weakened; excessive Tg reduction will lead to the lack of rigid components of PSA, resulting in the decline of adhesion and creep resistance, so the comprehensive performance of PSA will be reduced. By using crosslinking modified PSA, the system can form a cross-networking structure, which can effectively enhance PSA’s peeling strength, adhesive strength, and creep resistance, which can effectively solve the balance problem between PSA’s peeling strength, adhesive strength, and initial adhesive strength, and also improve PSA’s tensile strength, adhesive strength, heat resistance, and water resistance at high temperature.

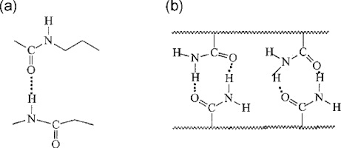

Generally, the crosslinking modification method is to introduce monomers containing alkenes or reactive functional groups in the copolymer, so that the copolymer macromolecular chain can be connected with the crosslinking groups; Then the copolymer reacted with the hydroxyl group, carboxyl group, and epoxy group to achieve the purpose of crosslinking modification.

Carboxyl or hydroxyl crosslinking modified PSA not only increased the crosslinking density and spatial network structure of the polymer but also affected the entangling degree between the polar molecular chains on the surface of the PSA polymer, which had an impact on PSA. The peeling strength, initial adhesion, and holding adhesion of the two components play a key role. The creep resistance, bonding, and tensile properties of PSA were effectively improved by the crosslinking reaction. Suitable crosslinking agents are available in varying degrees. Improve PSA’s heat resistance, water resistance, and film-forming properties.

Leave a Reply

Want to join the discussion?Feel free to contribute!