Knowing various things about PE protective film

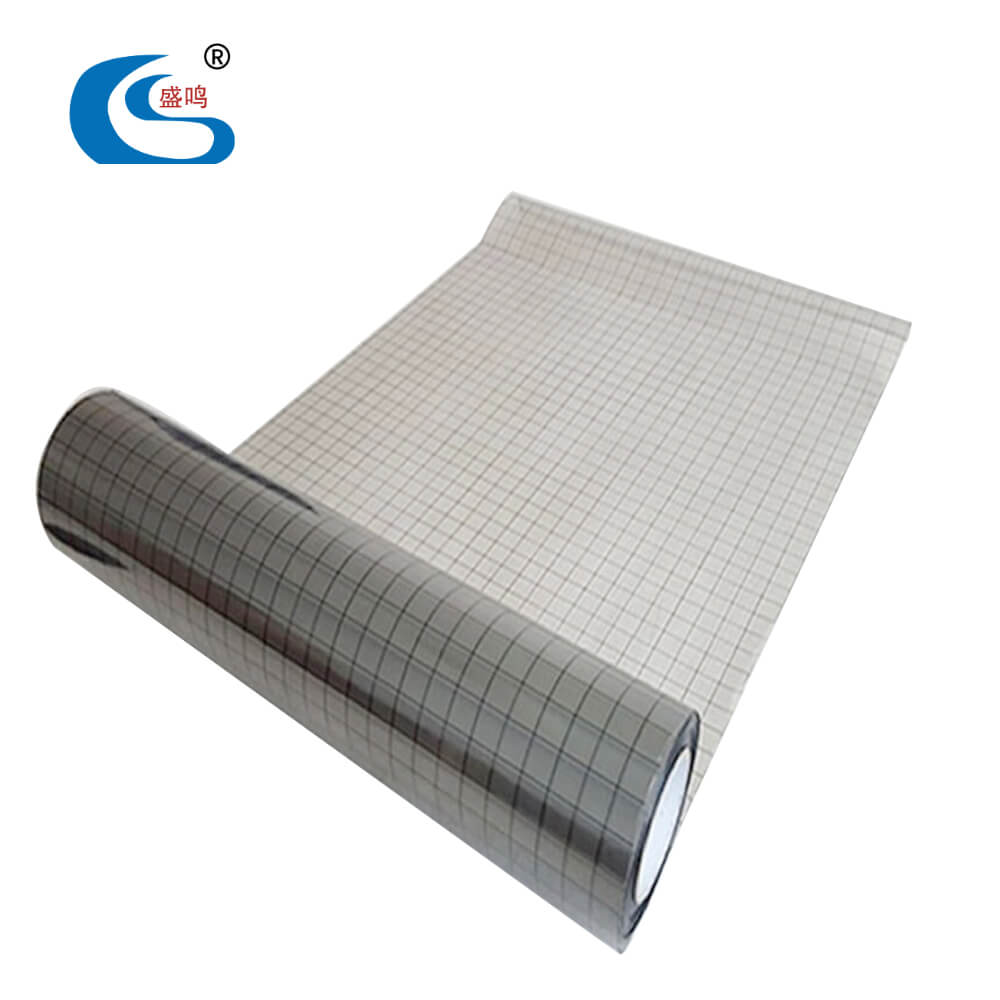

Polyethylene protective film, also known as PE protective film, is widely used in finished products to protect them from scratches, dirt, damage, and other issues. It is a thin layer of plastic that provides more safety for various items. PE is a non-toxic and environmentally friendly product that helps preserve the quality of a product. It uses pressure-sensitive adhesive coating and special polyethylene film to get the desired outputs.

Advantages of using PE protective film

- Provides more protection for surfaces

The primary advantage of PE protective film is that it provides more protection to surfaces during the storage, manufacturing, and transportation processes. Moreover, it acts as a barrier to several products to reduce unwanted problems.

- Enhances the aesthetics

PE protective film allows surfaces to maintain their original appearances to make sure that they are in good condition. This is important for high-end products that require high aesthetics.

- Easy removal

PE protective films adhere firmly to surfaces and are easily removable without leaving residue. This will simplify the cleanup process, which will help keep the protected surfaces in their original condition.

- Highly resistant to UV and weather conditions

Using PE protective films enables products to be protected from UV and other problems to get the best results. Besides, the weather-resistant properties of films make them suitable for outdoor applications. They are highly resistant to rain, wind, and bad weather which can affect the quality of finished products.

- Ideal for special applications

PE protective film is suitable for special applications such as glass, aluminum, plastics, and painted surfaces. It absorbs minor impacts, thereby showing ways to prevent scratches and other problems to a large extent.

- Cost savings

Using PE protective films reduces the need for repairs, replacements, and reworks and gives ways to save more money.

Knowing the performance of PE protective films

- Low-viscosity protective film

A low-viscosity protective film has a temperature resistance of up to 60 degrees. It is suitable for stable and good adhesion applications, which offer better peeling performance. The film is the best choice for nameplates, titanium metal, silk screen printing, and steel mirror plates.

- Medium-viscosity protective film

A medium-viscosity protective film has a peel strength of 60 to 80 g/cm and an elongation that is less than 400. Some of the applications of medium-viscosity protective film include stainless steel plates, artificial stones, ceramic tiles, etc.

- High-viscosity protective film

A high-viscosity protective film has a width of less than or equal to 1.3 and a peel strength starting from 80 g/cm to 100 g/cm. It is suitable for aluminium-plastic boards, fine-grained matte boards, etc.

- Ultra-low-viscosity protective film

It has a peel strength of less than or equal to 5 g/cm and can stand up to 60 degrees. The film is ideal for display screens, plastic lenses, instruments, etc.

- Ultra-high-viscosity protective film

Ultra-high-viscosity protective film is a water-based acrylic acid film that can be used as a pressure-sensitive adhesive. It has no residual glue phenomenon and is easy to stick and tear, which will save time.

What are some of the material properties of PE protective films?

PE protective films have excellent dielectric properties and are lighter than water. They are insoluble in common solvents and are lighter in weight. Moreover, a PE protective film has a certain degree of transparency and excellent chemical stability and is highly resistant to various chemical substances.

Buying high-quality protective films from Wuxi Changsheng

Wuxi Changsheng is one of the reputed manufacturers of PE protective films in China and offers high-quality products to wholesalers and others. All our products undergo several tests and processing techniques to make sure that they cater to the needs of end-users. We follow the best practices and the latest methodologies in the production process that provide temporary protection for several products.

Our products are suitable for the hardware industry, the optoelectronics industry, the printing industry, the construction industry, the manufacturing industry, the mobile phone industry, etc. Furthermore, they are eco-friendly and don’t cause any problems for the environment. They are easy to apply to surfaces and allow users to remove them without any hassle.

Why choose us?

- Better performance

Wuxi Changsheng provides PE protective films in various sizes, enabling users to ensure better performance.

- Cost-effective

Our PE protective films are cost-effective and provide more protection to surfaces, and clients can order them based on their budget.

- Suitable for different applications

PE protective films offered by our company are suitable for different applications, which help retain the quality of products.

- Customer Guidance

Wuxi Changsheng offers guidance to customers with expert teams to learn more about our products and other things in detail. Our customer support team will work closely with clients to evaluate their requirements while buying PE protective films.

Anyone who wants to get more details about our PE protective films can contact us by mail or phone.

Leave a Reply

Want to join the discussion?Feel free to contribute!