What is film-coated paper adhesive, and what are the film-coating materials?

Film-coated paper adhesive is a special type of adhesive used to bond film-coated paper or laminated paper. Film-coated paper is a common printing and packaging material typically composed of one or more layers of film or coating applied to the surface of paper to provide additional protection, enhance appearance, or serve specific functional purposes.

Film-coated paper adhesive typically possesses the following characteristics:

- Adhesion: This adhesive usually has strong adhesion to ensure that the film coating on film-coated paper adheres tightly to the paper’s surface, preventing it from peeling or separating.

- Compatibility with various materials: Film-coated paper adhesive needs to be compatible with different types of paper and film-coating materials to meet the requirements of various projects.

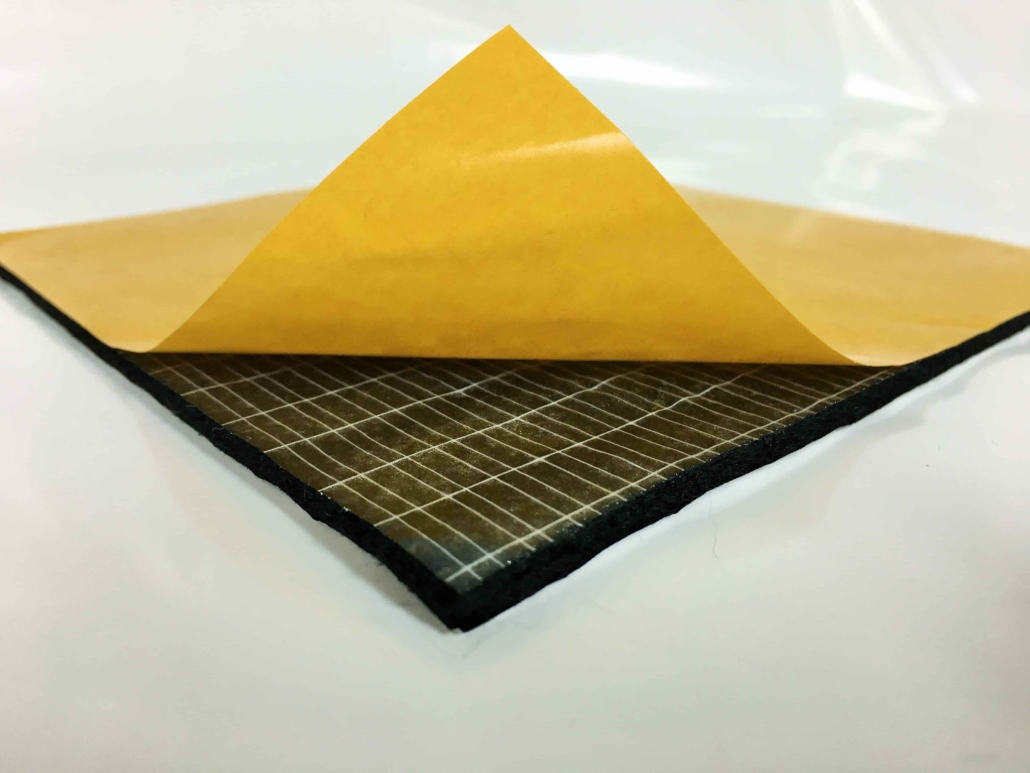

- Adaptation to different film-coating techniques: Film-coated paper may use various film-coating techniques, such as heat lamination, cold lamination, or pressure-sensitive lamination. Therefore, the adhesive needs to be adaptable to these diverse application methods.

- Quick drying: This adhesive typically needs to dry rapidly to ensure efficient production processes.

- Durability: Film-coated paper is commonly used in packaging, labels, posters, etc., where durability is essential. Therefore, the adhesive must have sufficient durability to ensure the long-term stability of the lamination.

Film-coated paper adhesive is often used in the printing and packaging industry to produce various products such as book covers, food packaging, advertising posters, brochures, labels, and more. The choice and use of this type of adhesive are crucial because they directly impact the appearance and performance characteristics of the printed products.

Film-coated paper adhesive is usually applied to bond cardstock (paper or cardboard) with various types of film-coating materials to provide additional protection, enhance durability, improve appearance, or serve specific functions. Here are some common film-coating material types:

- BOPP Film (Biaxially Oriented Polypropylene Film): BOPP film is a transparent polypropylene film commonly used for printing, packaging, and label making. It can be adhered to cardstock using film-coated paper adhesive to provide a glossy appearance and protection.

- PET Film (Polyethylene Terephthalate Film): PET film is a robust, transparent film widely used for book covers, brochures, advertising posters, and other printed materials. Cardstock adhesive can be used to attach PET film to cardstock, providing durability and visual appeal.

- PVC Film (Polyvinyl Chloride Film): PVC film is a transparent and durable film often used for book covers, folders, greeting cards, and labels. Cardstock adhesive can be used to bond PVC film to cardstock.

- PE Film (Polyethylene Film): PE film is commonly used for food packaging, bags, labels, and more. It can be attached to cardstock using cardstock adhesive to provide a flexible covering and protection.

- Metal Films: Metal films like aluminum foil or copper foil can be attached to cardstock using cardstock adhesive for specific applications such as antistatic packaging and heat insulation.

- Satin Finish Film: Satin finish film is typically used to create a satin or matte surface effect, often applied to book covers and brochures. It can be adhered to cardstock using cardstock adhesive to achieve a special tactile and visual appearance.

- Matte and Dull Finish Films: These films are used to create a matte or semi-matte surface effect and are often employed in high-end printing and packaging.

- Thermal Laminating Films: These are special laminating materials used in thermal lamination. They can be attached to cardstock using cardstock adhesive to provide protection and special effects for printed materials.

The above list includes some common types of film-coating materials, but there are many other types of laminating materials available. The choice of suitable film-coating materials and adhesives is crucial because they directly influence the appearance, performance, and durability of cardstock products.

If you are interested in our products, please feel free to contact us!

Leave a Reply

Want to join the discussion?Feel free to contribute!