Which types of MDF require protective film, and the pros and cons of different protective films

(一) Medium Density Fiberboard (MDF) is commonly used for various applications such as furniture, flooring, wall panels, decorative surfaces, and more. Protective film is often used to safeguard the surface of MDF boards from damage, contamination, or wear and tear. Here are some common types of MDF boards that may require the use of protective film:

- Furniture Panels: MDF is frequently used in crafting furniture like tables, chairs, cabinets, etc. Protective film can preserve the surface of furniture, preventing scratches and dirt.

- Flooring Panels: MDF flooring typically needs a durable surface to withstand foot traffic and furniture pressure. Protective film can enhance the durability of the floor.

- Wall Panels: MDF wall panels are used for wall decoration, providing a smooth appearance and insulation. Protective film can protect the surface of wall panels.

- Decorative Panels: MDF decorative panels are used for custom decor, such as closet doors, wall decorations, door frames, etc. Protective film can maintain the appearance of decorative panels.

- Cabinet Panels: MDF is used for making kitchen and bathroom cabinet panels, and protective film can prevent moisture damage to cabinet surfaces.

- Carved Panels: Some MDF boards are used for carving and cutting to create decorative carved items. Protective film can safeguard the carved surface.

(二) The use of protective film can be customized based on specific application needs to ensure that the MDF surface remains undamaged during production, transportation, and installation. Protective films are typically temporary and can be easily removed once the MDF panels are installed.

Different types of MDF protective films have their own advantages and disadvantages:

– Pros:

– Relatively low cost, cost-effective.

– Provides basic surface protection against scratches and dirt.

– Cons:

– Not suitable for long-term protection, prone to wear and tear.

– Not ideal for applications requiring high abrasion resistance.

-

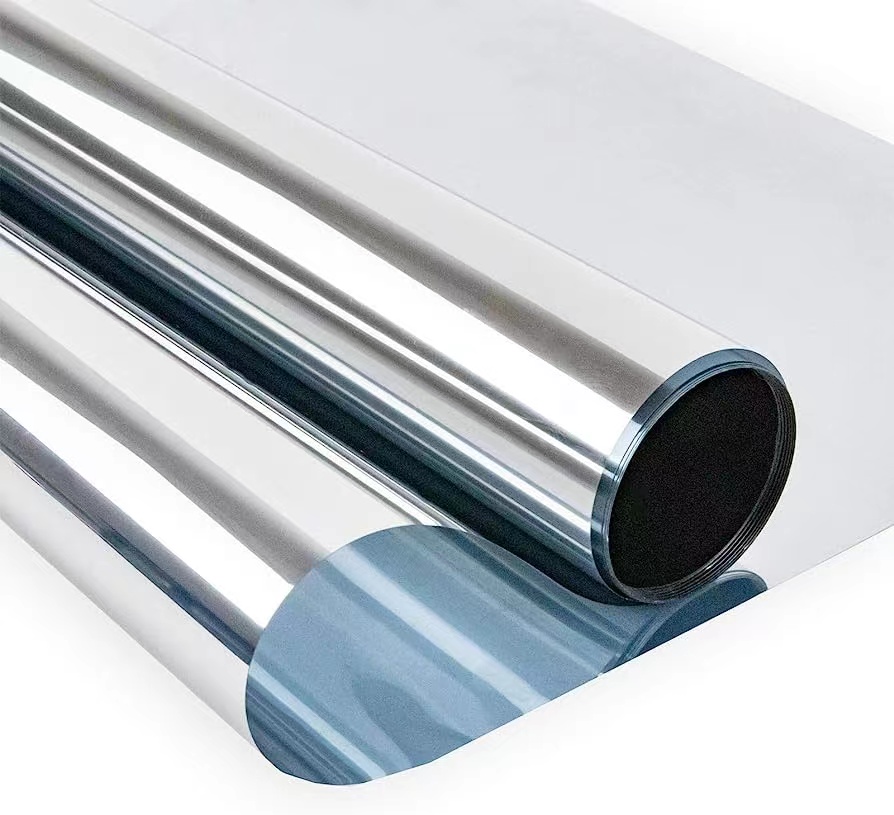

PVC (Polyvinyl Chloride) Protective Film:

– Pros:

– Strong abrasion resistance, suitable for long-term protection.

– Offers better water and chemical resistance.

– Cons:

– Can make the surface opaque in some cases.

– May not be as easy to handle and remove in certain situations.

– Pros:

– Good transparency, preserving the appearance of the MDF surface.

– Some abrasion and scratch resistance.

– Cons:

– Not as chemically resistant as PVC.

– Relatively thin, may not be suitable for highly abrasive applications.

-

Paper Protective Film:

– Pros:

– Biodegradable, environmentally friendly.

– Suitable for short-term protection, like during transport and assembly.

– Cons:

– Less abrasion resistance compared to other materials.

– Prone to moisture damage or tearing.

-

Self-Adhesive Protective Film:

– Pros:

– Easy to install, no need for glue or tape.

– Typically easy to remove without leaving residue.

– Cons:

– Some types may not provide as much surface protection as other film materials.

The choice of the appropriate MDF board protective film should consider the board’s intended use, environmental conditions, expected lifespan, and budget. Different protective film types offer various performance and appearance characteristics, so a careful assessment is required when making a selection.

If you are interested in our products, please feel free to contact us.

Leave a Reply

Want to join the discussion?Feel free to contribute!