Analyze the functions of glass protective film

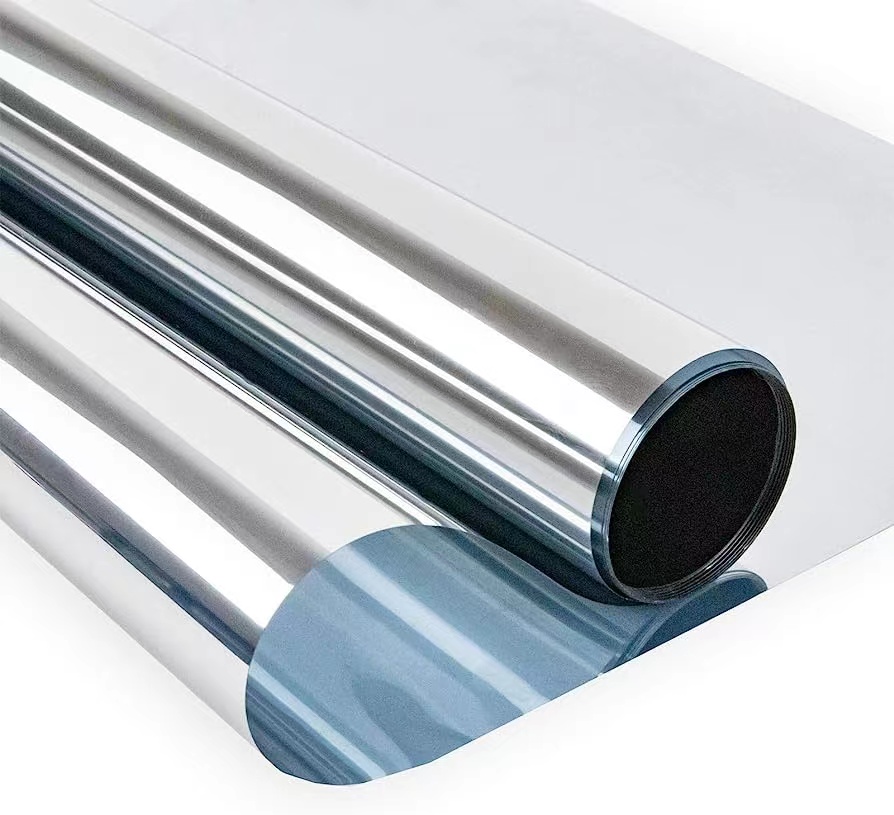

Glass protective film is a thin film or coating used to protect the surface of glass. Its primary purpose is to shield glass from damage, scratches, dirt, ultraviolet radiation, and other external factors. This protective film is typically transparent or semi-transparent and does not significantly alter the appearance of the glass.

However, it offers various functions and advantages, as follows:

- Scratch and Wear Resistance: Glass protective film can reduce scratches and wear on the glass surface, thereby extending the lifespan of the glass.

- Dirt Resistance: It minimizes dirt, water stains, and other contaminants from adhering to the glass surface, making cleaning easier.

- UV Radiation Protection: Some glass protective films can block ultraviolet radiation, helping to reduce fading and damage to indoor furniture, flooring, and decorations.

- Safety: Certain glass protective films can hold glass fragments together in case of glass breakage, reducing the risk of splintering and enhancing safety.

- Privacy Protection: Some glass protective films can reduce transparency or increase privacy by obstructing external views.

- Temperature Control: Specific types of glass protective films can assist in regulating indoor temperatures, reducing heat entry or loss, and improving energy efficiency.

Glass protective films are commonly applied to various glass surfaces, including windows, glass doors, glass walls, glass furniture, and more. They find wide-ranging applications in residential, commercial, and automotive sectors. Different types of glass protective films possess distinct characteristics and functions, and the choice depends on specific requirements. These protective films are typically easy to install, adhering to the glass surface, and can be replaced or removed as needed.

What type of protective film is needed when cutting glass?

During the glass-cutting process, it is typically necessary to use a specialized type of protective film to ensure that the glass surface remains safeguarded against scratches, damage, and contamination. The following are types of protective films used for cutting glass:

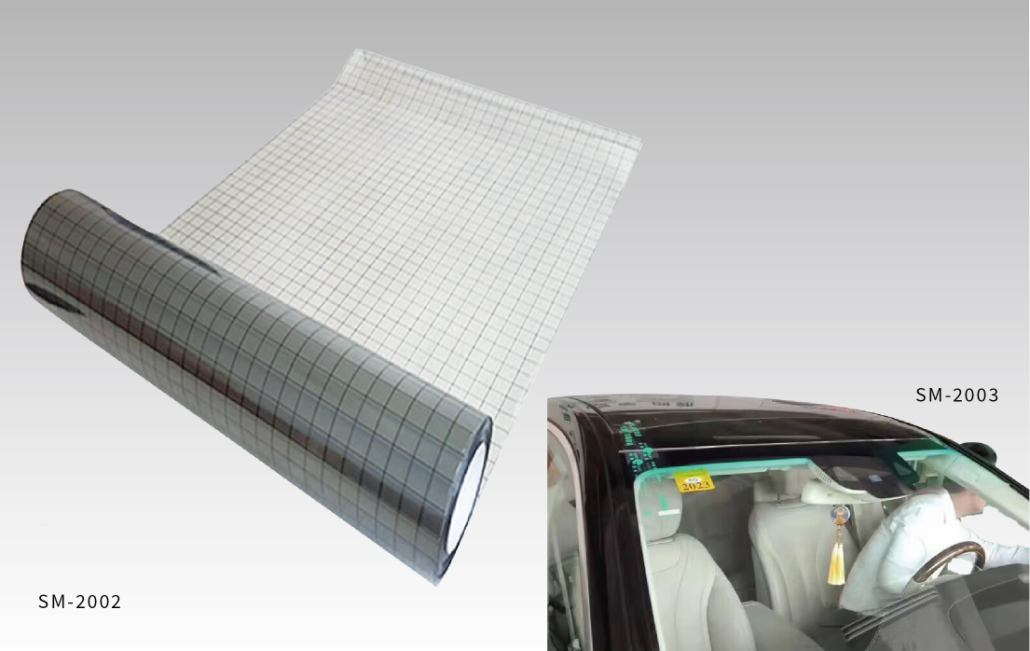

- Glass Cutting Protective Film: This type of protective film is specifically designed for safeguarding the glass surface during the glass-cutting process. It is usually a thin film with high transparency to allow glass craftsmen to see the cutting lines. Additionally, it provides the following protective functions:

– Scratch Resistance: It reduces the risk of scratches caused by glass cutters or cutting tools on the glass surface.

– Dirt Repellence: The protective film prevents dirt, oil stains, and water spots from adhering to the glass surface, ensuring clarity of the cutting lines.

– Safety: In case of glass breakage during cutting, the protective film helps prevent glass shards from scattering, enhancing operator safety.

- Double-Sided Adhesive Bottom Film: This type of protective film has adhesive on both sides, allowing it to adhere firmly to the glass surface. This helps ensure that the protective film does not slip or move during cutting, while also protecting the glass surface from scratches.

- Self-Adhesive Tape: Some glass craftsmen use self-adhesive tape to protect the glass surface during cutting. These tapes can be applied around the cutting lines to prevent scratches and provide protection. However, it is important to ensure that the selected tape is suitable for glass to avoid leaving adhesive residue or damaging the surface.

When choosing a glass-cutting protective film, factors to consider include:

- Glass Type: Different types of glass (e.g., regular glass, tempered glass, laminated glass) may require different types of protective films to accommodate their surface characteristics and strength.

- Cutting Tools: Depending on the cutting tools used (such as glass cutters or glass cutting machines) and the cutting methods, the appropriate protective film should be chosen.

- Cutting Environment: Consider the humidity, temperature, and other factors of the cutting environment to determine the required protective film type and performance.

- Operator Safety: Ensure that the selected protective film provides sufficient safety to reduce the risk of accidental injuries.

- Removal and Cleanup: Select protective films that are easy to remove and clean to ensure that no residue is left on the glass surface after cutting.

In summary, choosing the appropriate glass-cutting protective film is crucial for safeguarding the glass surface and ensuring a smooth cutting process. The selection should be based on specific cutting requirements and processes.

What type of protective film is needed for glass during transportation?

During the transportation of glass, it is typically necessary to use a specific type of protective film to ensure that the glass remains undamaged and free from scratches, fractures, or contamination. The following are common types of protective films used during glass transportation:

- Transparent Plastic Sheeting: This type of protective film is usually a transparent plastic sheet that can cover the entire surface of the glass. It provides a protective layer to prevent scratches, dirt, and minor abrasions. Transparent sheeting allows for inspection of the glass’s condition while shielding it from external elements.

- Foam Cushion Layer Protective Film: This type of protective film comes with an integrated foam cushion layer designed to provide additional impact-absorbing protection. It helps prevent glass from shattering or getting damaged during transportation due to collisions or impacts.

- Double-Sided Adhesive Protective Film: This protective film has adhesive on the bottom side, allowing it to adhere to the glass surface and prevent the film from sliding or moving during transportation. This ensures that the protective film stays firmly attached to the glass, providing long-lasting protection.

- Paper-Backed Sheeting: This type of protective film has a paper backing on the bottom, similar to tape. It can be rolled out onto the glass, and the paper backing helps keep the film in place while making it easier to tear off when needed. This type of film is typically suitable for protecting large glass sheets.

When selecting the appropriate protective film for glass transportation, consider the following factors:

- Glass Type: Different types of glass (e.g., regular glass, tempered glass, laminated glass) may require different types of protective films to accommodate their characteristics and thickness.

- Mode of Transportation: Consider the mode of glass transportation (e.g., by truck, container, handling equipment) and the potential vibrations and impacts that the glass may encounter during transit.

- Glass Size: The size and shape of the glass will impact the type and quantity of protective film required.

- Safety: Ensure that the selected protective film prevents the glass from sliding, reducing the risk during transportation.

- Ease of Installation and Removal: Choose protective films that are easy to install and remove to enhance efficiency and reduce the risk of damage.

When transporting glass, ensure the correct installation and securing of the protective film to guarantee adequate protection for the glass. Regularly inspect the status of the protective film, especially during longer transportation processes, to ensure its effectiveness.

If you are interested in our products, please feel free to contact us.

Leave a Reply

Want to join the discussion?Feel free to contribute!