Customizable and Versatile: The Power of Our Adhesive Products in Diverse Industries

In today’s business landscape, adhesive products have become indispensable industrial materials. Manufacturers and businesses across various industries require high-quality adhesives to meet various bonding needs.

As a B2B manufacturer specializing in adhesive products, we take pride in our extensive range of adhesive products known for exceptional customizability and versatile applications, making us a popular choice in diverse markets.

Exceptional Customizability

As adhesive suppliers, we understand that different industries and customers have distinct bonding requirements. Therefore, our adhesive product range emphasizes customizability to meet specific demands. Whether it’s high-strength adhesives for automotive assembly or micro-adhesives for electronic device assembly, we can provide tailored solutions to meet your needs.

Our research and development team boasts extensive experience and expertise, allowing us to customize adhesive products based on precise customer requirements. Whether it’s adjusting bond strength, adhesion properties, or weather resistance, we can fine-tune our products to align with your unique specifications. This high degree of customizability ensures that our adhesive products can cater to the demands of various industries and applications, providing customers with optimal solutions.

Versatile Application Across Industries

Our adhesive products find wide-ranging applications across various industries, including but not limited to automotive manufacturing, electronics, medical, construction, and packaging.

In the automotive manufacturing industry, our adhesive products are extensively used in body assembly, interior assembly, and sealing. They not only exhibit excellent bonding performance but also feature high-temperature resistance, weather resistance, and resistance to chemical corrosion, ensuring stable performance under various challenging conditions.

In the electronics sector, our adhesive products are employed in circuit board assembly, encapsulation, and heat dissipation. They offer outstanding electrical insulation properties and maintain stability even in high-temperature environments, ensuring the reliability and durability of electronic devices.

In the medical field, our adhesive products are widely used in medical device assembly and encapsulation. With excellent biocompatibility, they are safe for use in medical equipment manufacturing and also possess antimicrobial properties, contributing to the hygiene and safety of medical devices.

In the construction industry, our adhesive products are utilized for various structural bonding, sealing, and insulation applications. They exhibit excellent weather resistance and durability, ensuring the longevity and safety of building structures.

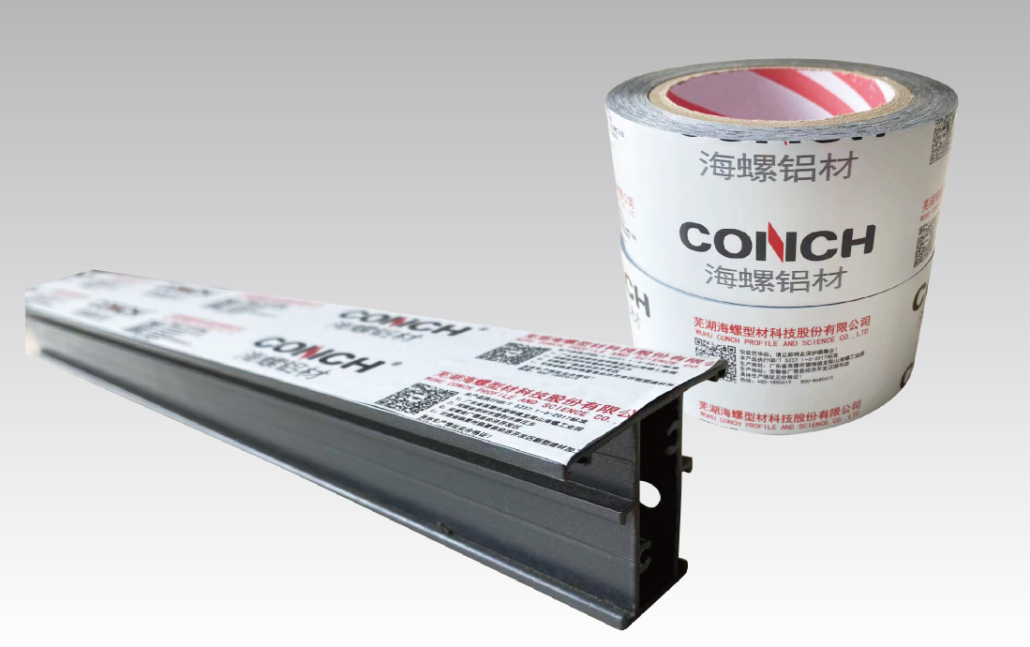

In the packaging sector, our adhesive products are employed for sealing and securing various packaging materials. They offer superior adhesion and sealing properties, ensuring the integrity and freshness of packaged goods.

Conclusion

As a B2B manufacturer specializing in adhesive products, our offerings feature exceptional customizability and versatile applications. Whether you work in automotive manufacturing, electronics, medical, construction, or packaging, we can provide adhesive product solutions tailored to your needs. Our products not only deliver outstanding bonding performance but also offer high-temperature resistance, weather resistance, and resistance to chemical corrosion, ensuring exceptional performance in diverse application conditions.

If you are in search of a reliable adhesive supplier, consider choosing us. Our team is dedicated to providing customized solutions to meet your bonding requirements. We believe that with our exceptional products and services, your projects will achieve greater success. Regardless of the scale of your project, we are willing to be your partner in growth and development.

Leave a Reply

Want to join the discussion?Feel free to contribute!