What kind of protective film do European and American customers generally choose

When choosing the material of the protective film, European and American customers usually tend to choose materials with high quality, environmental protection, and sustainability.

The following are some protective film materials commonly used by European and American customers:

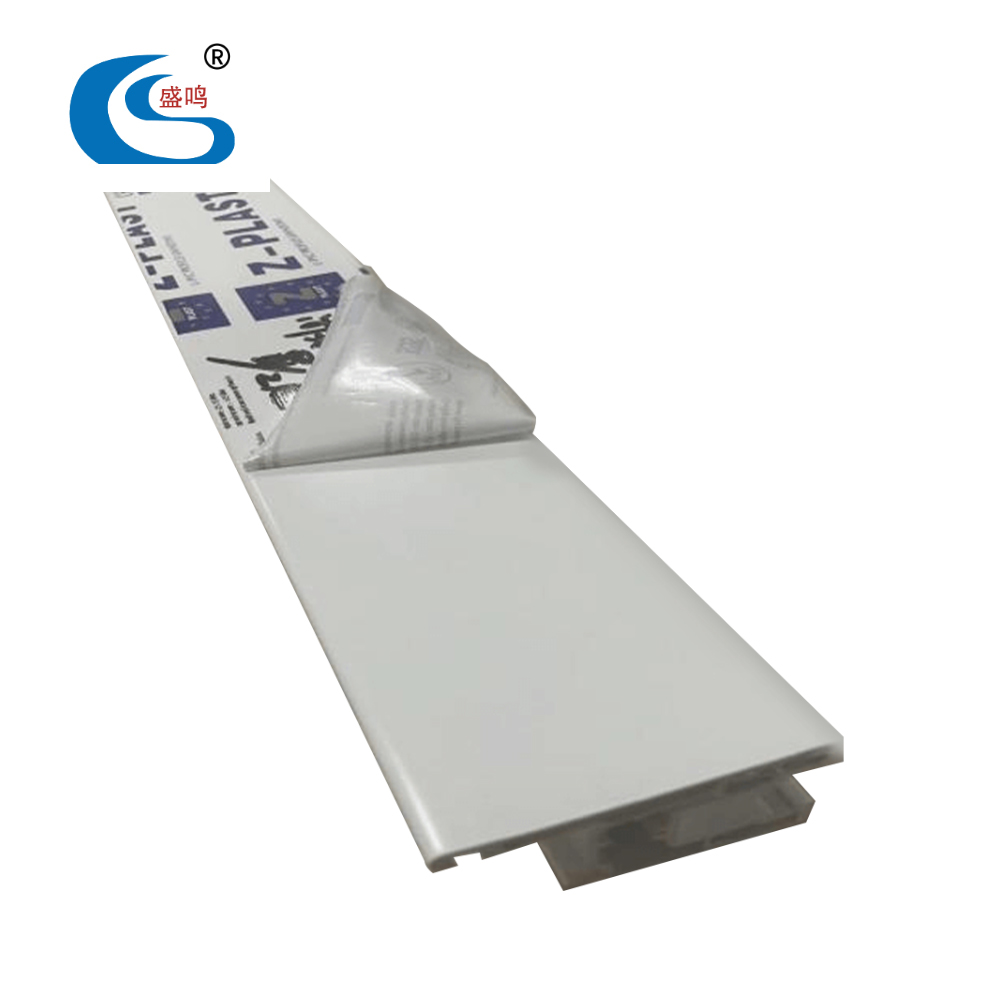

- Polyethylene (PE) film: Polyethylene film is a common protective film material, with good durability and transparency. It is suitable for a variety of applications, including electronics, furniture, glass, etc.

- Polypropylene (PP) film: Polypropylene film usually has high durability and thermal stability, suitable for applications requiring higher temperature resistance, such as industrial equipment protection.

- PET film: PET (polyethylene terephthalate) film has excellent transparency, durability, and heat resistance. It is widely used in electronic products, mobile phones, display screens, and other fields.

- PU film (polyurethane): Polyurethane film is usually used for higher levels of protection, such as high-end furniture, automotive interiors, etc. It has excellent wear and chemical resistance.

- Biodegradable film: In the case of increasing environmental awareness, some European and American customers choose protective films made of biodegradable materials to reduce the impact on the environment. These materials can decompose under certain conditions and do not pose long-term harm to the environment.

- Silicone film: Silicone film has good heat resistance, cold resistance, and chemical stability, usually used in electronic products, medical equipment, and other fields.

- TPU film (thermoplastic polyurethane): TPU film has good elasticity and durability, suitable for products requiring flexible protection, such as curved surfaces or equipment.

European and American customers usually choose the right protective film material according to the type of object they need to protect, application scenarios, environmental considerations, and high-quality requirements. Different materials of protective film have different characteristics and applicability, manufacturers need to be flexible to adjust their product lines according to market demand.

If you are interested in our products, please contact us!

Leave a Reply

Want to join the discussion?Feel free to contribute!