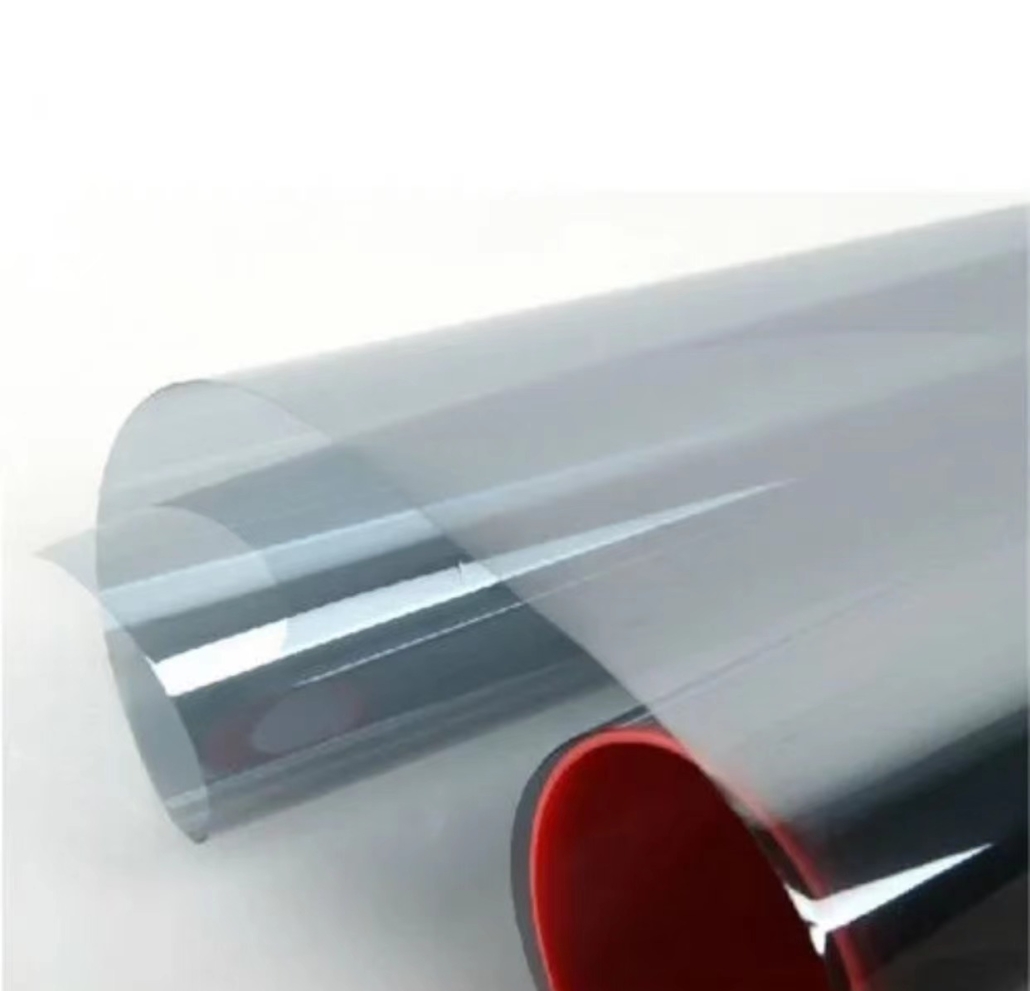

Reasons for the layer of protective film

The reasons for the lamination of protective film can be many, usually involving material quality, manufacturing process, environmental factors, etc.

Here are some common causes that can cause layer of protective film:

- Poor material quality: If the quality of the material used is unstable or does not meet the requirements, there may be non-uniformity within the material, or the adhesion of the material is not good enough, which may lead to the lamination of the protective film in use.

- Manufacturing process problems: The process of manufacturing the protective film may affect the layering problem. If the temperature, pressure, coating speed, and other parameters in the manufacturing process are not properly controlled, it may lead to uneven bonding of the material, resulting in delamination.

- Poor adhesion: The protective film needs to be firmly attached to the substrate or the surface of the protected object. If the attachment is not good, stratification may occur during use.

- Temperature and humidity changes: Changes in temperature and humidity may cause the material of the protective film to expand or contract, thus affecting the bonding performance. Especially under extreme temperature and humidity conditions, the delamination problem may be more prominent.

- Chemical reaction: The chemical properties of the protective film and the surface of the protected object may interact, resulting in a chemical reaction of the material, resulting in delamination. For example, chemical incompatibility can lead to material separation between the protective film and the object being protected.

- External damage: The protective film may suffer physical damage during use, such as scratching, impact, etc., which may lead to the rupture or delamination of the film material.

- Storage and transportation conditions: the protective film is affected by environmental conditions such as temperature and humidity during storage and transportation, which may affect the stability and adhesion performance of the film, resulting in layering problems.

To avoid the lamination problem of protective film, manufacturers usually need to ensure that the material quality is stable, the manufacturing process is reasonable, the adhesion is good, and extreme environmental conditions are avoided during use. In addition, the correct use and maintenance methods can also reduce the risk of protective film delamination.

If you are interested in our products, please contact us!

Leave a Reply

Want to join the discussion?Feel free to contribute!