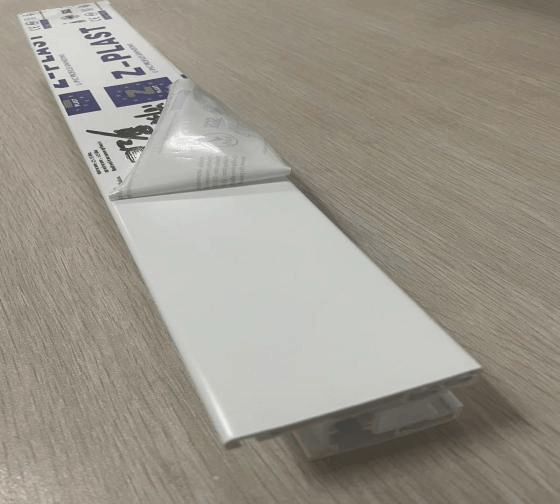

Low-viscosity protective films can be used on smooth surfaces

Low-viscosity protective films typically have lower adhesion and higher wearability, allowing them to adhere more easily to smooth surfaces and be easily peeled off without leaving residue or damaging the surface.

They provide an effective protective layer to prevent physical and chemical damage such as scratches, impacts, and chemical corrosion. For smooth surfaces like glass, aluminum alloy, and stainless steel, using low-viscosity protective films can provide the following benefits:

1. Protection against scratches and damage: The protective film reduces the risk of scratches and damage to the smooth surface, keeping it intact and extending its lifespan.

2. Prevention of contamination and corrosion: The protective film prevents contact and corrosion from contaminants and chemicals, keeping the surface clean and durable.

3. Convenient removal: Low-viscosity protective films are easy to peel off without leaving residue or contaminating the surface, facilitating subsequent processes and use.

4. Improved product quality: The use of protective films maintains the appearance and quality of the smooth surface, enhancing overall product quality and market competitiveness.

It is important to choose the appropriate low-viscosity protective film product based on specific application needs and to clean and prepare the surface before application to ensure effective protection.

If you are interested in our products, please feel free to contact us!

Leave a Reply

Want to join the discussion?Feel free to contribute!